my 24v build, slightly different than the norm. Now with dyno numbers!

Collapse

X

-

With the drama this engine/your builld has gone through you should set up a R3v meet/celebration for the fireup. -

Stopped by the machine shop and saw my engine and some other fun stuff.

Here is one of my Metric Mechanic coated bearing$$$ that has 10-15 minutes of run time on it...

busted_bearing by 2mAn

busted_bearing by 2mAn

the block still looks nice

bareblockpt2 by 2mAn

bareblockpt2 by 2mAn

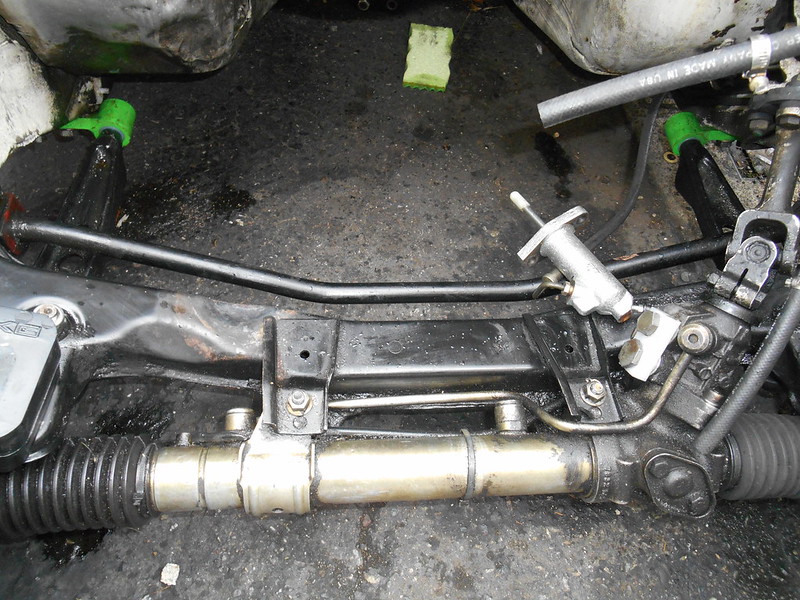

I snapped this pic so you could see some of the fun stuff that you will never see later. AKG motor mounts, Silence Power Steering delete, Treehouse CABs, and the subframe modified for the S50 downpipe

details by 2mAn

details by 2mAn

So, I had to order a Timesert BIGsert kit and according to the engine builder, engine might be assembled and ready to go by the end of the week. Kevin said he just needs one day to assemble the engine and install it into the car. I am planning on a final (one way) trip in February, but haven't bought a ticket yet. I just might be driving this car soon. Fingers crossed....Leave a comment:

-

Bought a one way ticket for 1/9/14, now it looks like I'll need to get myself a return ticket. At least now I can clean the engine bay since there still wont be an engine in it.Leave a comment:

-

Hi,this post is very helpfull!! thanks

i've see your m50 harness scheme and i need to ask if you have check if it's all correct, looks great!Leave a comment:

-

-

Yea he tried to help save me some money by doing some work myself and I was pretty nervous about some of the stuff I was doing, and tried really hard to be extra careful but I still failed. Live and learn.Leave a comment:

-

Glad to see this is still moving forward.

Kevin is a solid dude. It seems like a lot of issues were caused by not having a single person do all the assembly.

Also it just seems like there was some first timer mistakes. Don't worry, it happens to us all and its how we learn to be more careful next time and what to look for.Leave a comment:

-

Engine build #2 is almost done, I think early January Im flying up. Before then I'll decide whos installing the engine. Still leaning towards having him do it (crazy, right??) but I still think thats the best way to do it. We've chatted more lately and he seems to understand my pain. In the end, he is WAY more experienced than me and Id trust his work over mine. Its obvious Ive made some costly mistakes.Leave a comment:

-

So you had a spun bearing? I take it the bearings were aftermarket. Where they miced prior to assembly?Leave a comment:

-

It was a clusterfuck my last week in Seattle. Between working and packing for a 1200mile move AND trying to get the E30 into a position to be swapped that was one thing that the mechanic NEVER mentioned until AFTER the motor was being torn out. Hindsight, the ~4 -8 hours of his labor I saved by doing a little bit of work myself has not been worth it at all because Ive already spent that AGAIN... like I said, this whole thing has killed my E30 boner#1 rule. Always check clearances! Parts suppliers make mistakes, the head/block could have been decked, ect. Any of that can cause piston/valve clearance issues.

I have seen people pull parts from one engine and put them in another and have interference issues. Each motor is unique, always measure/verify.

The motor ran for no more than 15 minutes before it was determined to be ruined. A lot of theories are being thrown around about what happened. Machine shop is trying to say that having only one of two dowels caused the head gasket to fail. Mechanic thinks the head didnt get torqued down properly. Machine shop also said that my time-serting caused metal to ruin one of the bearings, but I have yet to see any evidence besides a ruined bearing. I would tihnk metal would ne in the oil filter screen also. I was pretty anal about any metal shavings getting into my fresh block. Then theres the question of WHY I would drill the timeserts AFTER the block is assembled and not BEFORE. Again, bad communication between the mechanic and myself. Ultimately, Im the one who has spent a shitload of money and still doesnt have a car

/rantLeave a comment:

-

You said the motor failed. So you actually had the motor running? Obviously, I'm only looking at pictures but if the piston in your picture is at TDC it "looks" correct.Leave a comment:

-

#1 rule. Always check clearances! Parts suppliers make mistakes, the head/block could have been decked, ect. Any of that can cause piston/valve clearance issues.

I have seen people pull parts from one engine and put them in another and have interference issues. Each motor is unique, always measure/verify.Leave a comment:

-

I think something else is going on. Im kinda bummed by all of this and stay off of R3V and away from E30s in general because I get super bummed about all of this. I really want to know WHY the motor failed and so far I havent gotten many answers.

Thanks, its been a rollercoaster of emotions. Someday I will be driving this thing and it should be all worth it...Leave a comment:

Leave a comment: