Starting my M54B30 swap...

Collapse

X

-

Make a build thread!:up:Well guys, logic has set in and I've changed my mind yet again. This thread is now relevant to this forum again I'm putting the M54 into my E30 after all, it will make it so I have no downtime with my DD. I'll still be turboing it down the line. I need to order a new pair of engine mounts(probably urethane, love the ones in my E24) and I need to change the brake booster. Once that is done everything will be in line to drop the motor in.

I'm putting the M54 into my E30 after all, it will make it so I have no downtime with my DD. I'll still be turboing it down the line. I need to order a new pair of engine mounts(probably urethane, love the ones in my E24) and I need to change the brake booster. Once that is done everything will be in line to drop the motor in.Leave a comment:

-

Well guys, logic has set in and I've changed my mind yet again. This thread is now relevant to this forum again I'm putting the M54 into my E30 after all, it will make it so I have no downtime with my DD. I'll still be turboing it down the line. I need to order a new pair of engine mounts(probably urethane, love the ones in my E24) and I need to change the brake booster. Once that is done everything will be in line to drop the motor in.

I'm putting the M54 into my E30 after all, it will make it so I have no downtime with my DD. I'll still be turboing it down the line. I need to order a new pair of engine mounts(probably urethane, love the ones in my E24) and I need to change the brake booster. Once that is done everything will be in line to drop the motor in.

Leave a comment:

-

Worked more on my wiring today, found some errors I made and corrected them. Whoops.Leave a comment:

-

Took resistence measurements on my coolant temp sensor today. Need to pull the intake air temp sensor and do the same.Leave a comment:

-

It runs! Got it to start and idle on MS3. Had a small hiccup with the ICV but now it idles fairly well. Need to find a decent Ignition chart that doesn't go up to 300KPa.

See the progress at http://m54megasquirt3.blogspot.com/Leave a comment:

-

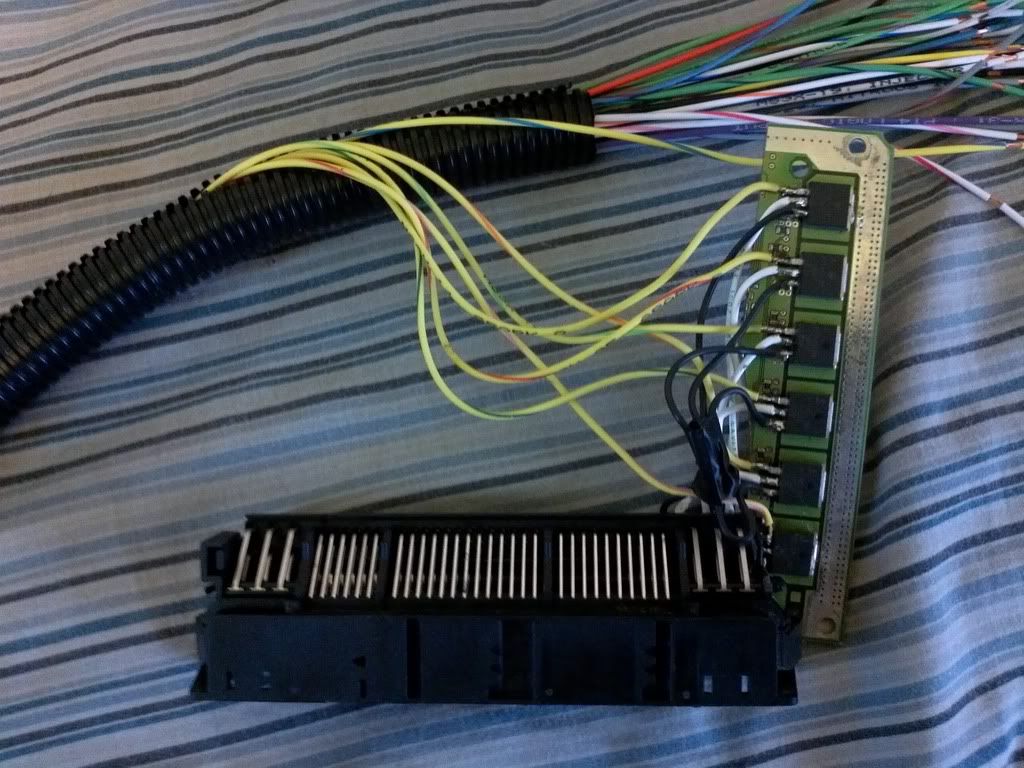

Here we go. I decided to have the drivers just go in order, 1-6. I sorted out the firing order in the MS3X harness. I've checked continuity and made sure there are no unintentional connections anywhere. I used the middle connector instead of the back connector for ease of soldering.Leave a comment:

-

There we go. Now to cut a pair of holes for the MS3X and main harness.Leave a comment:

-

Excellent, just picked up a Hakko 1300w heat gun.Yes, heat gun. hold the board in a vice. Make sure the connector isn't mechanically attached to the board in any way (screws, snaps, etc.). Practice on some of the chips to get a feel for the solder. Start on the end of the plug away from the coil drivers and work your way down. As you heat from the back gently pry and it will slide out like buttah.Leave a comment:

-

Yes, heat gun. hold the board in a vice. Make sure the connector isn't mechanically attached to the board in any way (screws, snaps, etc.). Practice on some of the chips to get a feel for the solder. Start on the end of the plug away from the coil drivers and work your way down. As you heat from the back gently pry and it will slide out like buttah.Leave a comment:

-

Oh good call, that'd make things a lot easier.

Would a heat gun be the best way to get the main connector off of the board?Last edited by Elysian; 09-19-2011, 10:52 AM.Leave a comment:

-

You could leave them on the board and cut the board out around them. That way they're mounted and have some heat sinkage.

You could then scrape off some of the protective screen and solder output directly to the pad.Leave a comment:

-

This is what I'm talking about, it's literally an epoxy. I also like to have this stuff handy because I also water-cool my computer, it helps when I need to attach something Guess I'm taking a trip to Frys for a heat gun and some Arctic Alumina.

Guess I'm taking a trip to Frys for a heat gun and some Arctic Alumina.

Leave a comment:

-

yeah you probably don't want to use a conductive paste (I've got a tube of arctic silver from 10 years ago!). I'd think the thermal tape would work best, it's more of a epoxy than a tape though.Leave a comment:

Leave a comment: