Soon. We have to make a testing tube to be accurate. A flange and a few inches of piping welded up will do the trick.

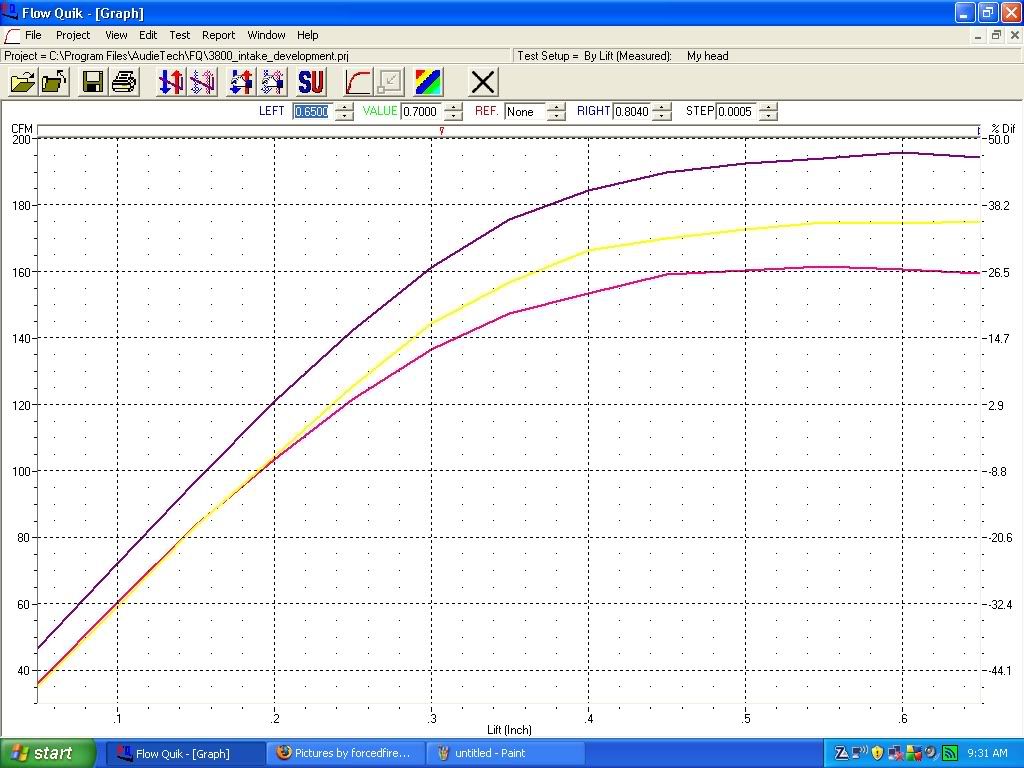

Today we will test the "ported" head fully to see how consistent the previous owner was.

Today we will test the "ported" head fully to see how consistent the previous owner was.

Comment