Well I am trying to keep it reasonably cheap hence the used Pistons, they were in really good shape apart from the number 1 ding. Ring lands measured out in spec. I guess I'm willing to gamble on them.

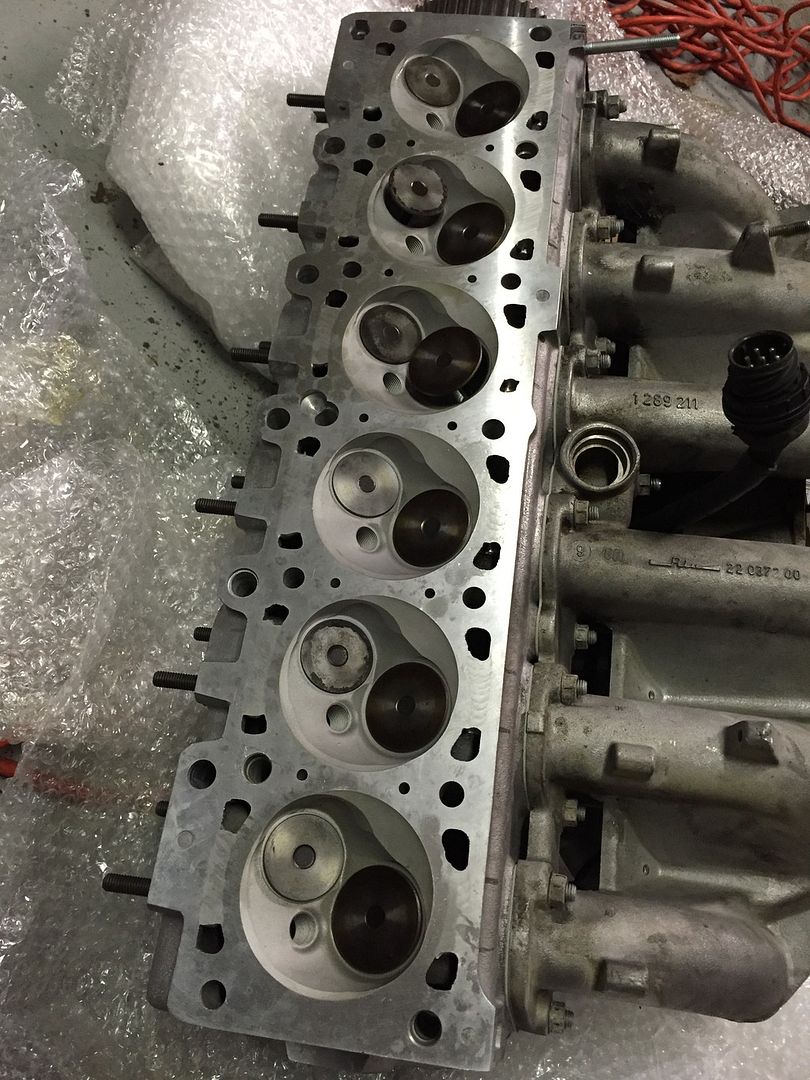

I asked the shop about the deck and he said he'd check it for flatness and machine if needed. He said it was perfect and not to mess with it. That plus the o rings have me pretty confident in the HG seal. Have you seen many warped deck surfaces on these motors?

I asked the shop about the deck and he said he'd check it for flatness and machine if needed. He said it was perfect and not to mess with it. That plus the o rings have me pretty confident in the HG seal. Have you seen many warped deck surfaces on these motors?

Comment