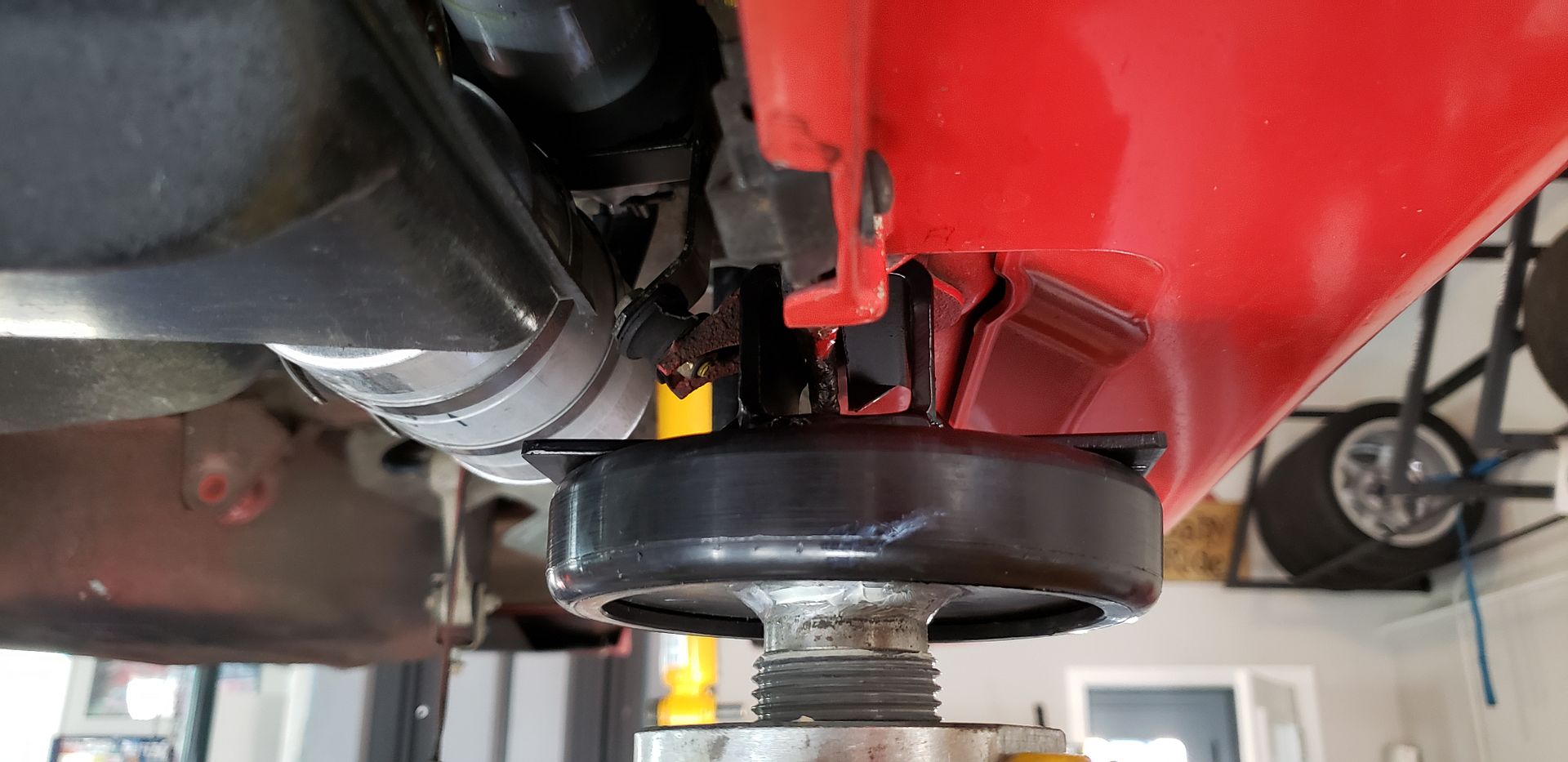

I am planning this job in the spring. I like what you did here dropping the entire assembly onto a rolling cart. Any idea of the weight of the entire subframe assembly? This cart looks decent, rated for 660lbs.

https://www.northerntool.com/shop/to...8589_200748589

https://www.northerntool.com/shop/to...8589_200748589

_20191221_123231.jpg)

Comment