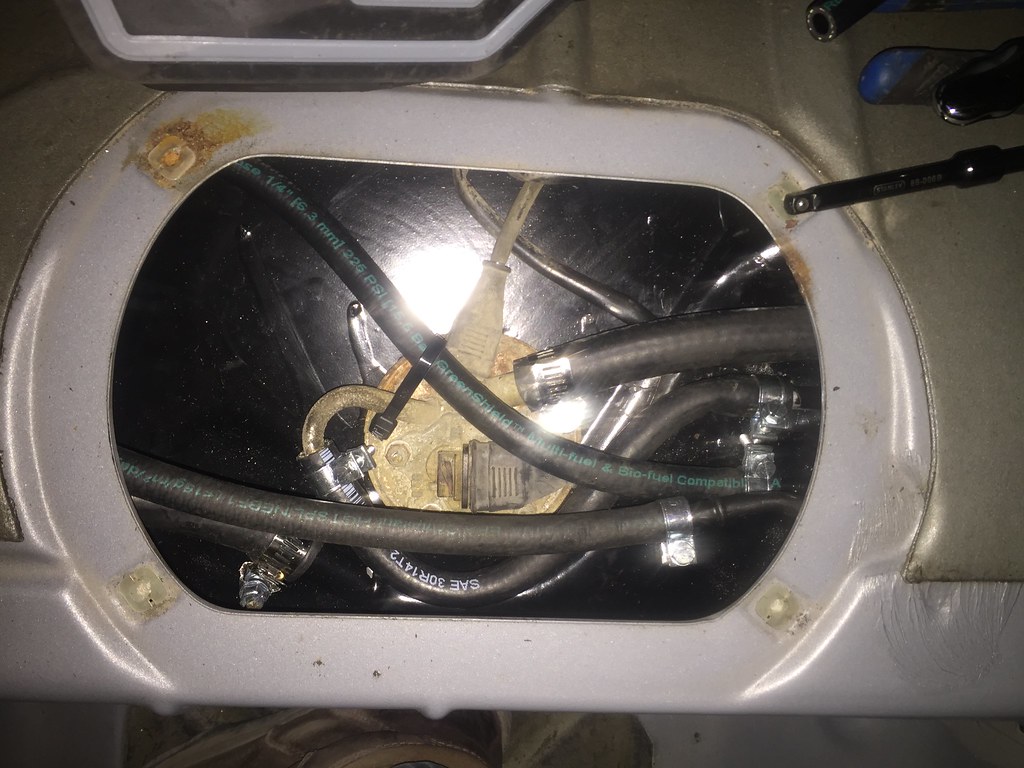

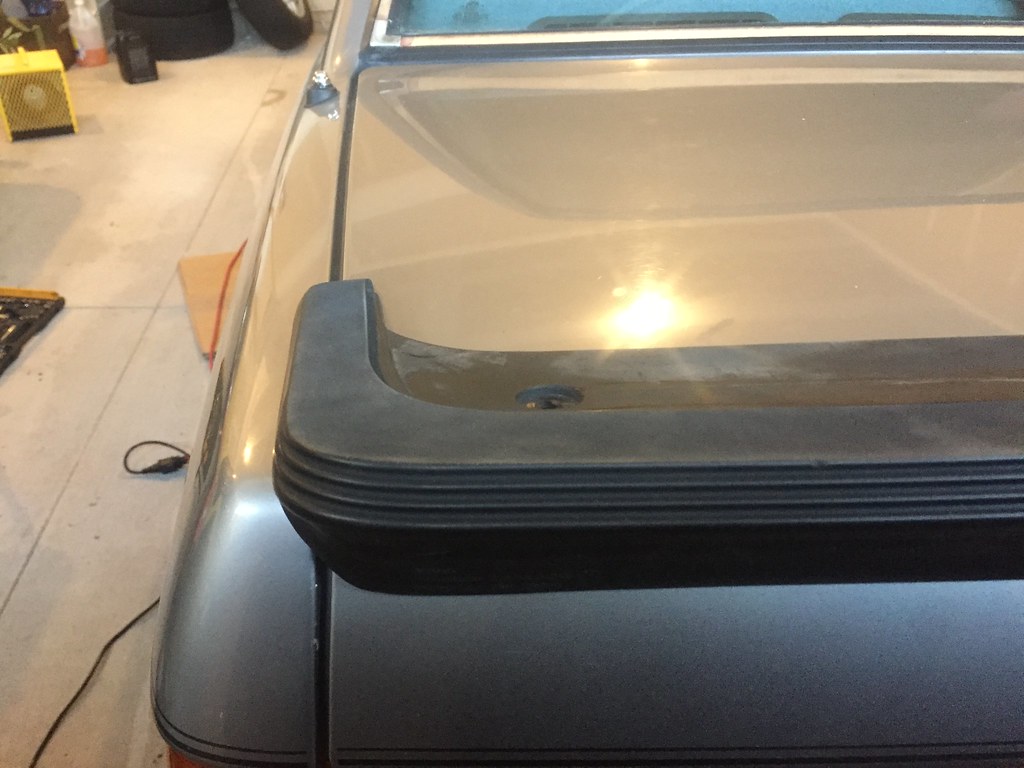

Continuing from the last post, here is today's progress in fixing the fuel vent rust.

This was my first time working with thin sheet metal, and I learned a few things in the process:

In summary, the situation is almost remedied. Another coat of paint tomorrow evening, and a quick cut of the rusted tube inside the car should see it resolved.

I'll update this post with some better finished/painted pictures tomorrow.

This was my first time working with thin sheet metal, and I learned a few things in the process:

- Don't use a reciprocating saw for fine work.

- If I had brought my jigsaw along, I could have removed less good metal on the body and made a smaller patch panel.

- Butt welding here was unnecessary, and made things more difficult.

- Lap joints would have been preferable.

- Don't try to fill in air gaps between your patch panel and the body. It'll just blow through (or you'll have to stack some welds very carefully).

- If butt welding, your patch panel must be the exact shape of the missing metal.

- Shop rags are flammable.

In summary, the situation is almost remedied. Another coat of paint tomorrow evening, and a quick cut of the rusted tube inside the car should see it resolved.

I'll update this post with some better finished/painted pictures tomorrow.

Comment