----------------

Another wash:

----------------

I changed the oil last week.

Running some Dino 20w50 for now (Castrol IIRC), at least for a few (reduced interval) changes.

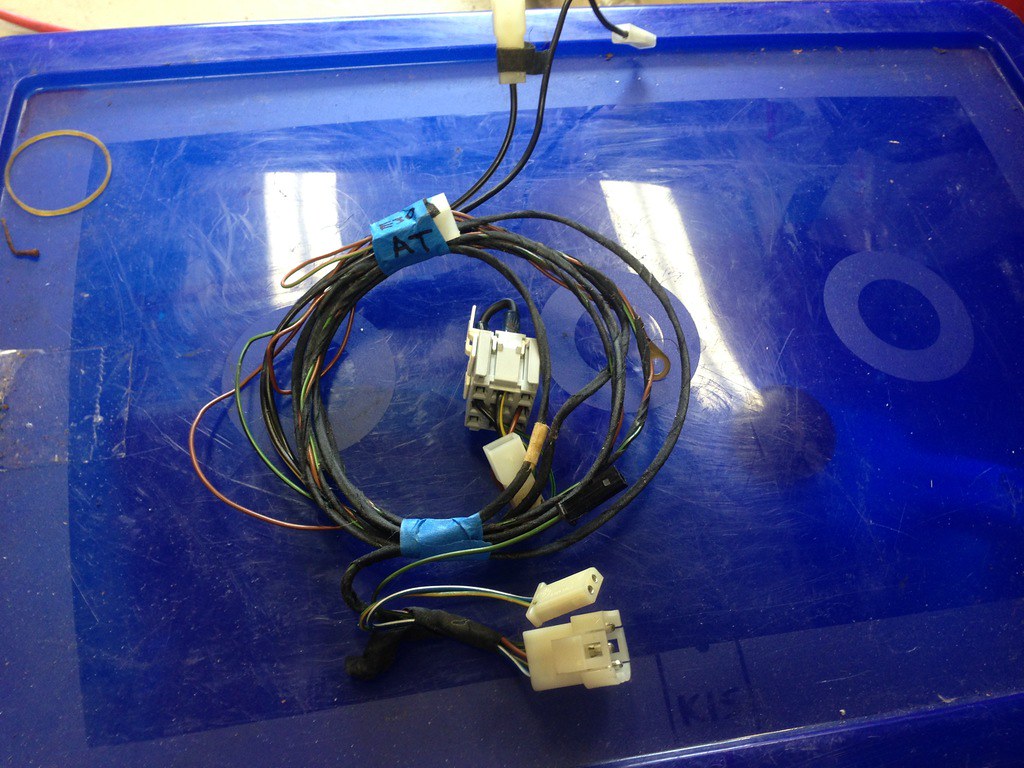

Also got tired of the lack of music, so I decided to try and make sense of how the previous owner had the stereo wired.

The crappy Sony headunit that was in the car when I bought it, had four pairs of wires running to the rear of the car, to the factory amp connector. They were crimped onto the factory speaker wires from there.

Unfortunately the factory amp was long gone. I had already stripped out the aftermarket wiring that was running from the headunit to the rear, so I set about using the factory wiring to run from the "headunit" to the amp connector.

Soldered and later heatshrunk the connections in the rear.

Interestingly enough, all four speakers share a common ground wire from the front of the car. It was originally intended to drive a low level signal to the factory amp, but in this case I'm using it to carry speaker-level current for all four speakers. This is definitely a bottleneck.

Then upfront, I did a quick and dirty job of wiring in a hefty 10 amp, 12v -> 24v step up DC-DC regulator along with a small Class-D amplifier board. These are both jammed behind the faceplate (on top of the climate control unit).

I am running both left (and both right) speakers in parallel right now, and I get the amp cutting out / bad distortion at medium volumes. I think the factory speakers are low impedance and in parallel are driving the amp down too low.

Anyways, I did a quick job of mounting a power switch and a 3.5mm aux jack beside my VDO gauge.

This setup is temporary until I get my other gauges installed, then I will probably hide the power and input switches, and potentially add balance and fade potentiometers.

I may also add a twin Class-D amp if I'm taxing the existing amp too much and that is the cause of my cut-outs. It's just as likely that there is a bad connection somewhere, as I did try to reuse as much of the (crimped) wiring that was left from the Sony HU, rather then cutting more off the factory harness.

When the other two VDO gauges go in, I'll probably be redoing all of the stereo wiring with fresh stuff, soldering all the connections as I go.

For now, I have more music then I did before!

----------------------

08/17/15 Update

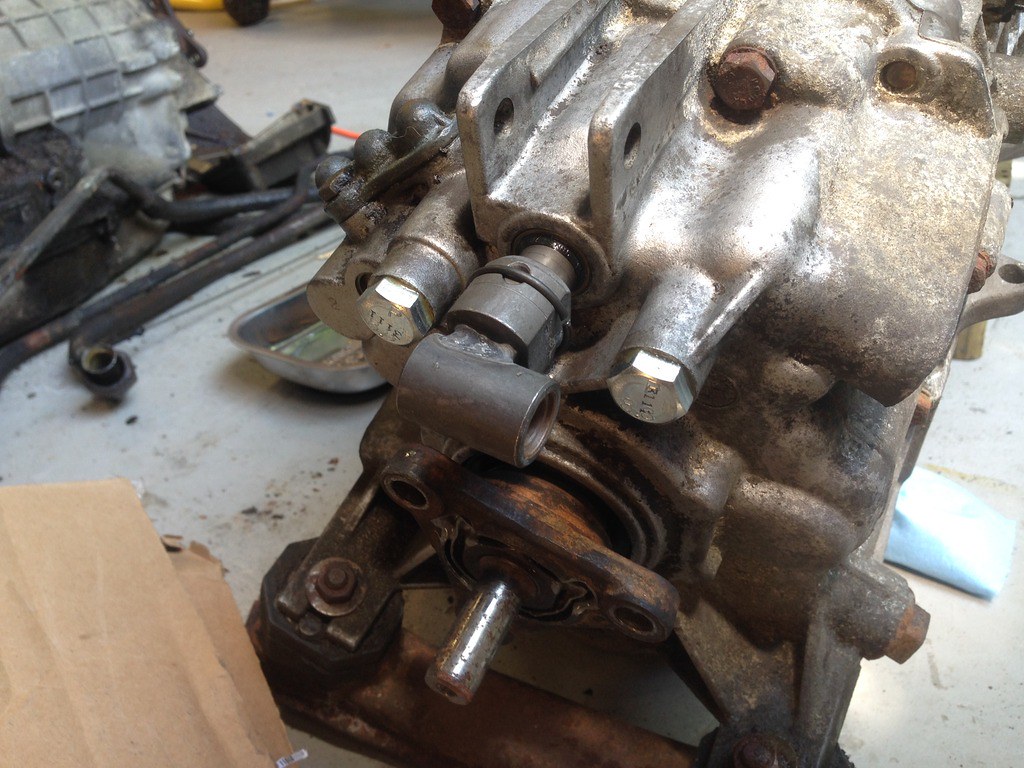

After putting about 2000KM on the car since the trans swap, I am comfortable enough saying that the clutch is broken in. I no longer get clutch chatter when slowly reversing either.

I gave it a good wheelspin launch the other day, and then proceeded to chirp both the 1-2 AND 2-3 shift. :D

The car is slowly turning into what I originally envisioned. Sporty when I want it, but still able to kick back, recline the sport seats, and cruise down the highway and relax.

----------------------

09/01/15 Update

E30 is still bringing a smile to my face whenever I drive it.

I changed the plugs today using a set of Bosch Super Plus (7909)

Here is a picture of the old plugs, mileage unknown. Sorry for the poor cellphone quality.

I was careful to clean out the plug recesses with compressed air, multiple times, before I removed the plugs.

I used antisieze and a small torque wrench to reassemble.

Car seems to idle a little better and has less hesitation under 2000rpm.

Leave a comment: