Subframe Refresh: Day 2

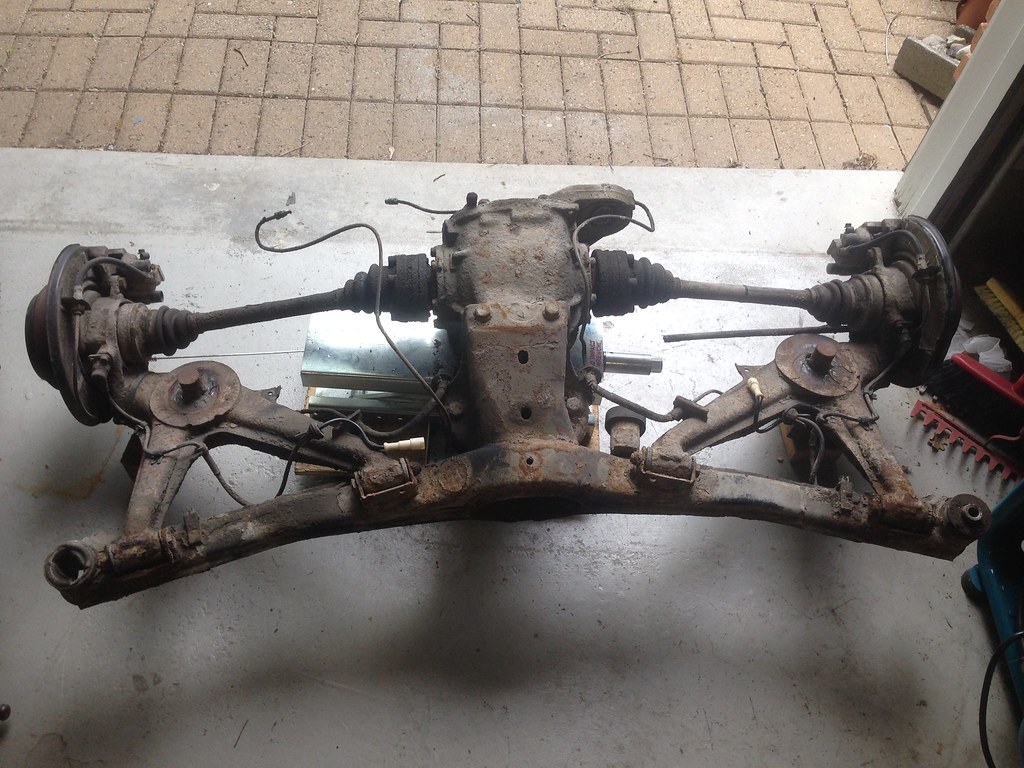

Separated the major components of the subframe today.

I didn't mess about with the very rusty trailing arm bolts. I scraped off all the crusty rust, and then hit them with the propane torch. Along with plenty of PB blaster in the last few days, they came off without issue.

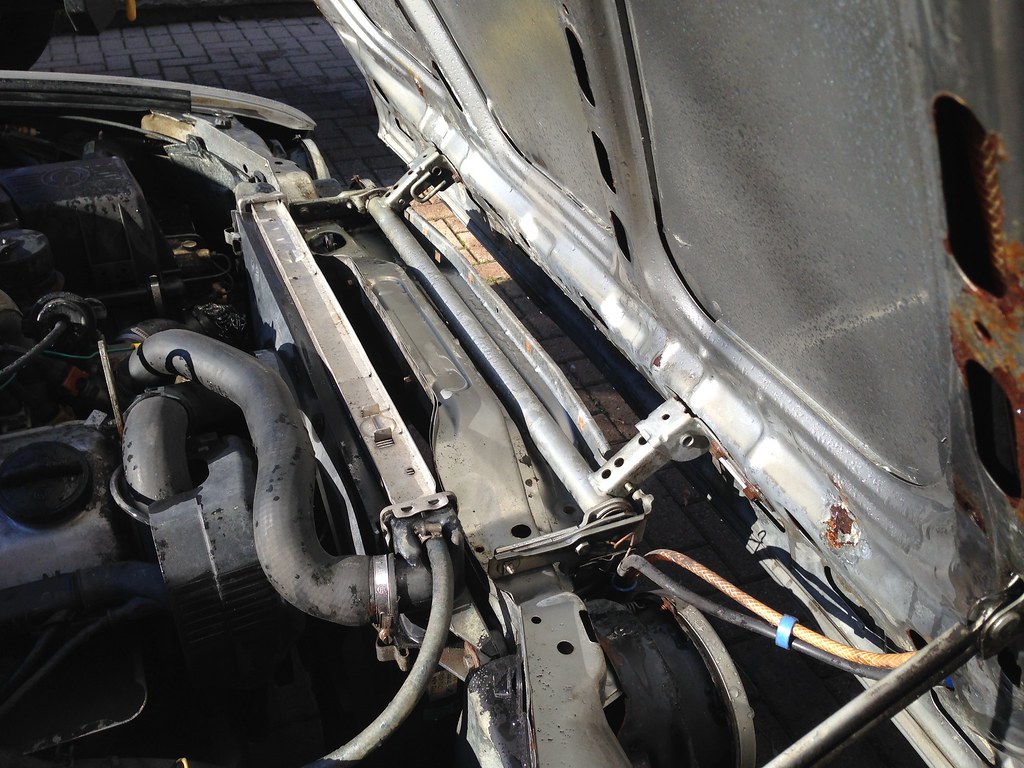

Discovered that my subframe has some major rust on the outer TA mounting points. I'm going to either have to find a local welder to get them reinforced, or find a replacement subframe.

Driver's side trailing arm off, showing the center locating pieces I had epoxied on in 2014. They were still solidly attached (enough to stop the spring from shifting should the suspension be completely unweighted)

Passenger side trailing arm off

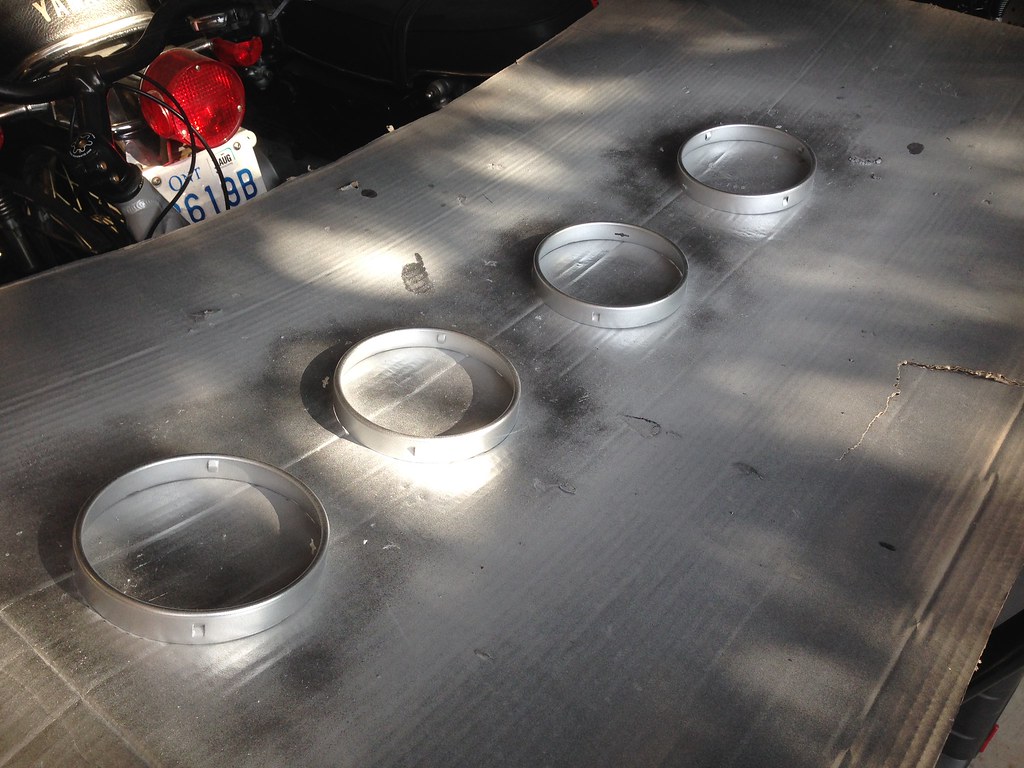

Workspace at the end of the day

Bagged and tagged hardware

Replacement trailing arms compared to the ones that came off the car. Take note of how nice the brake dust shields are on the old arms. I will be reusing these.

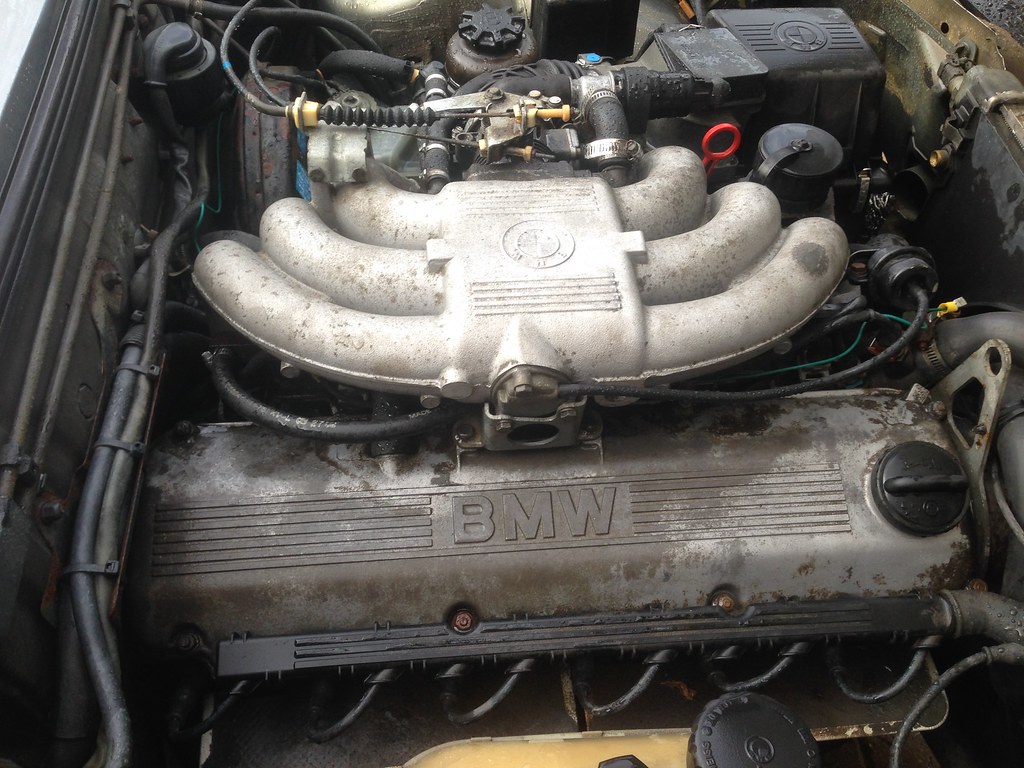

Subframe and differential after cleaning up all the dirt and tools. That jack I made up when I did the transmission swap last year, came in handy again today.

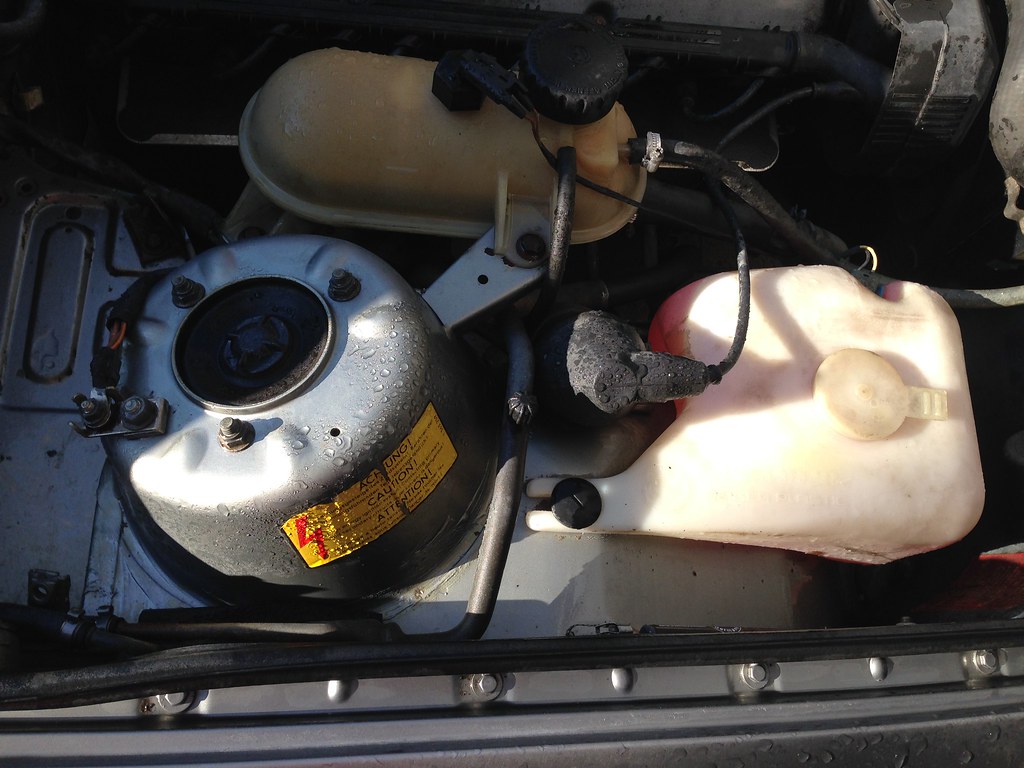

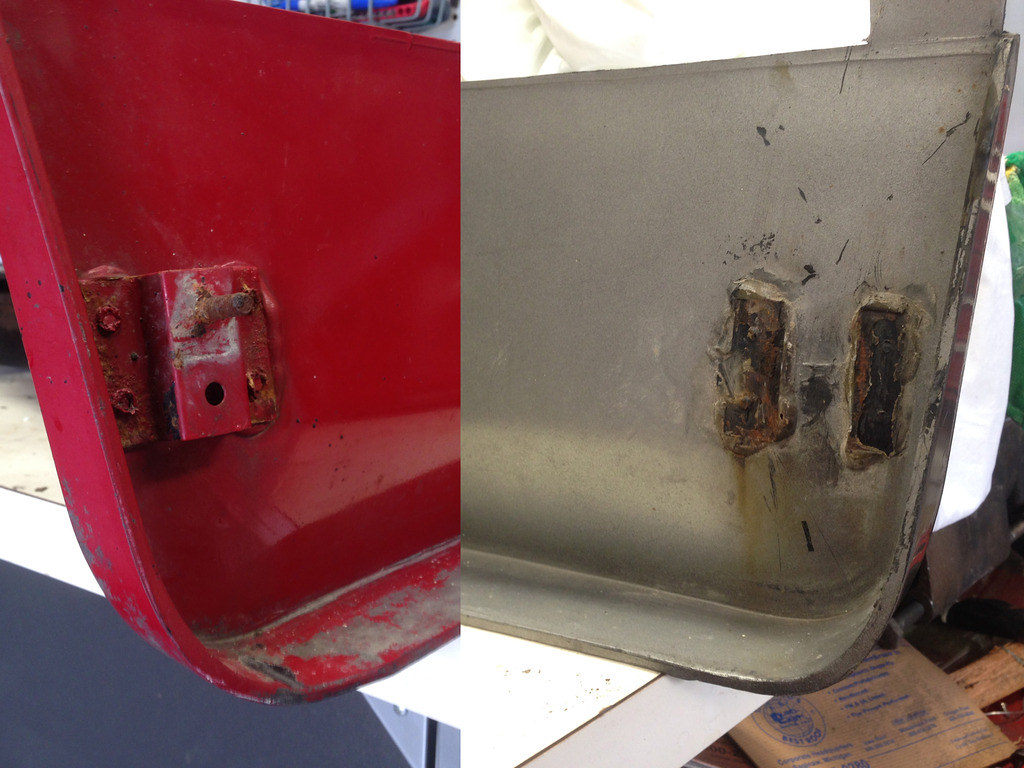

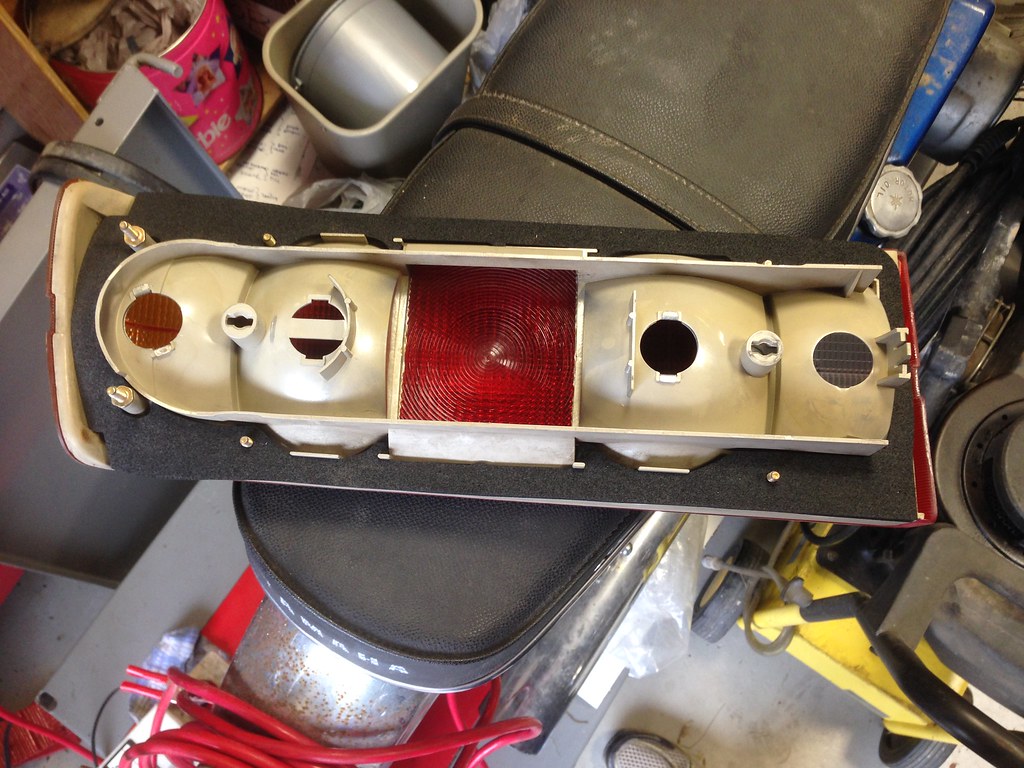

And the downer for the day.

Very rusty outer subframe mounts for the trailing arms.

The area was packed with undercoating, which trapped water all these years, and rusted the metal away. Similar to one of my front spring perches, which I replaced back in 2014.

Leave a comment: