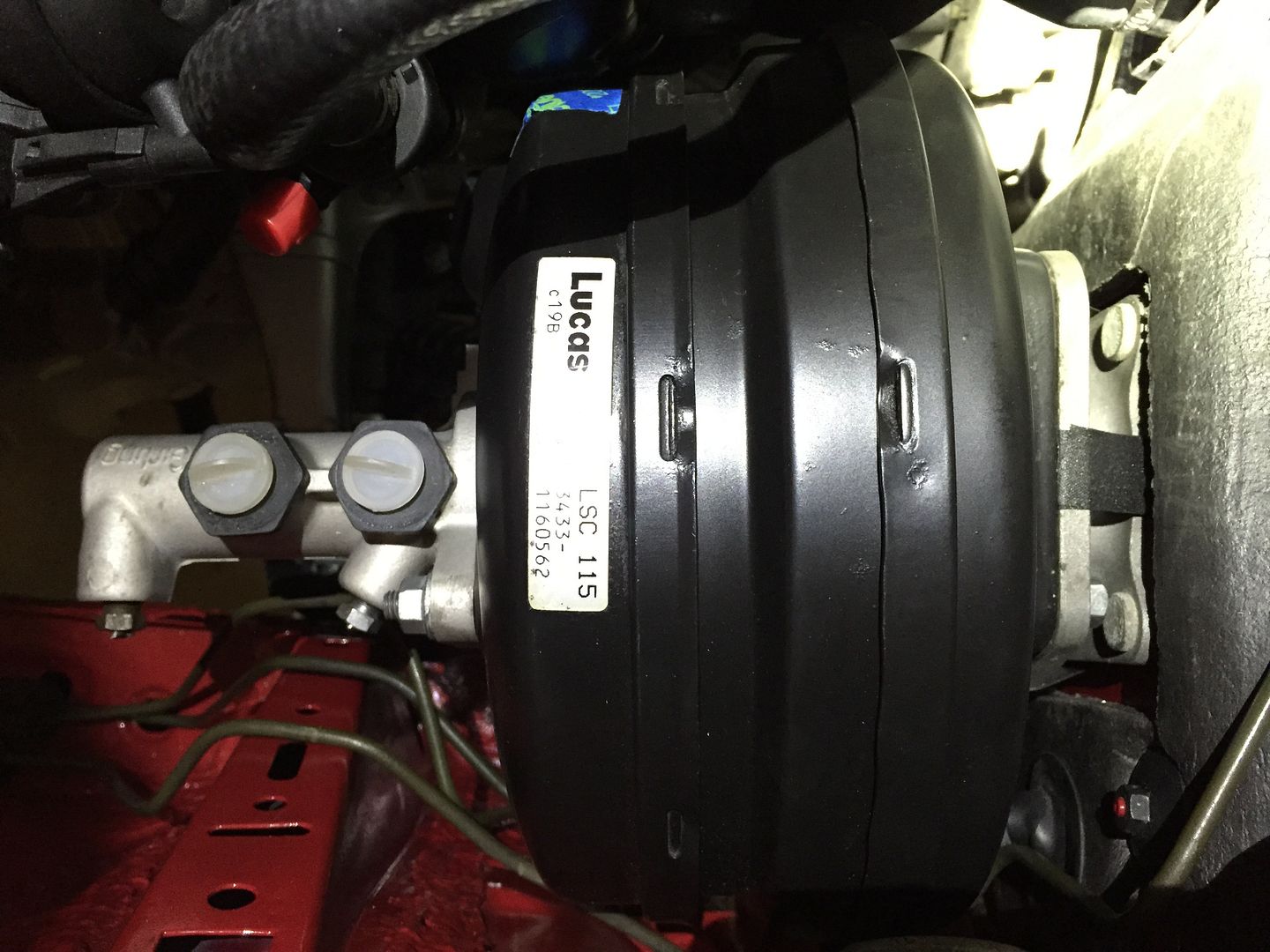

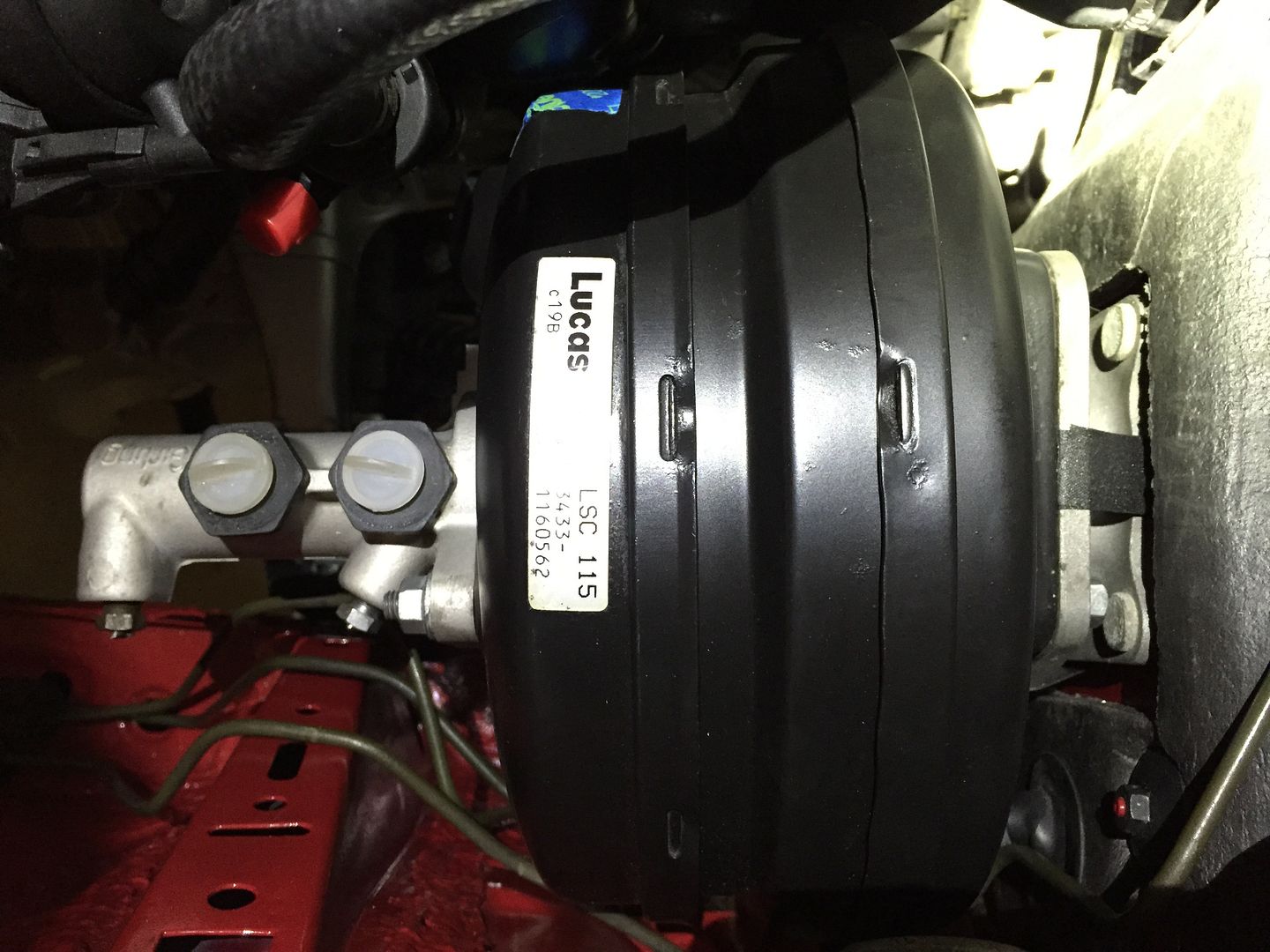

OK so this evening I decided to make my way back around to the brake booster snafu. After making some preliminary measurements I decided to go ahead and remove the booster and flip the angled aluminum bracket to see what kind of room that would make me.

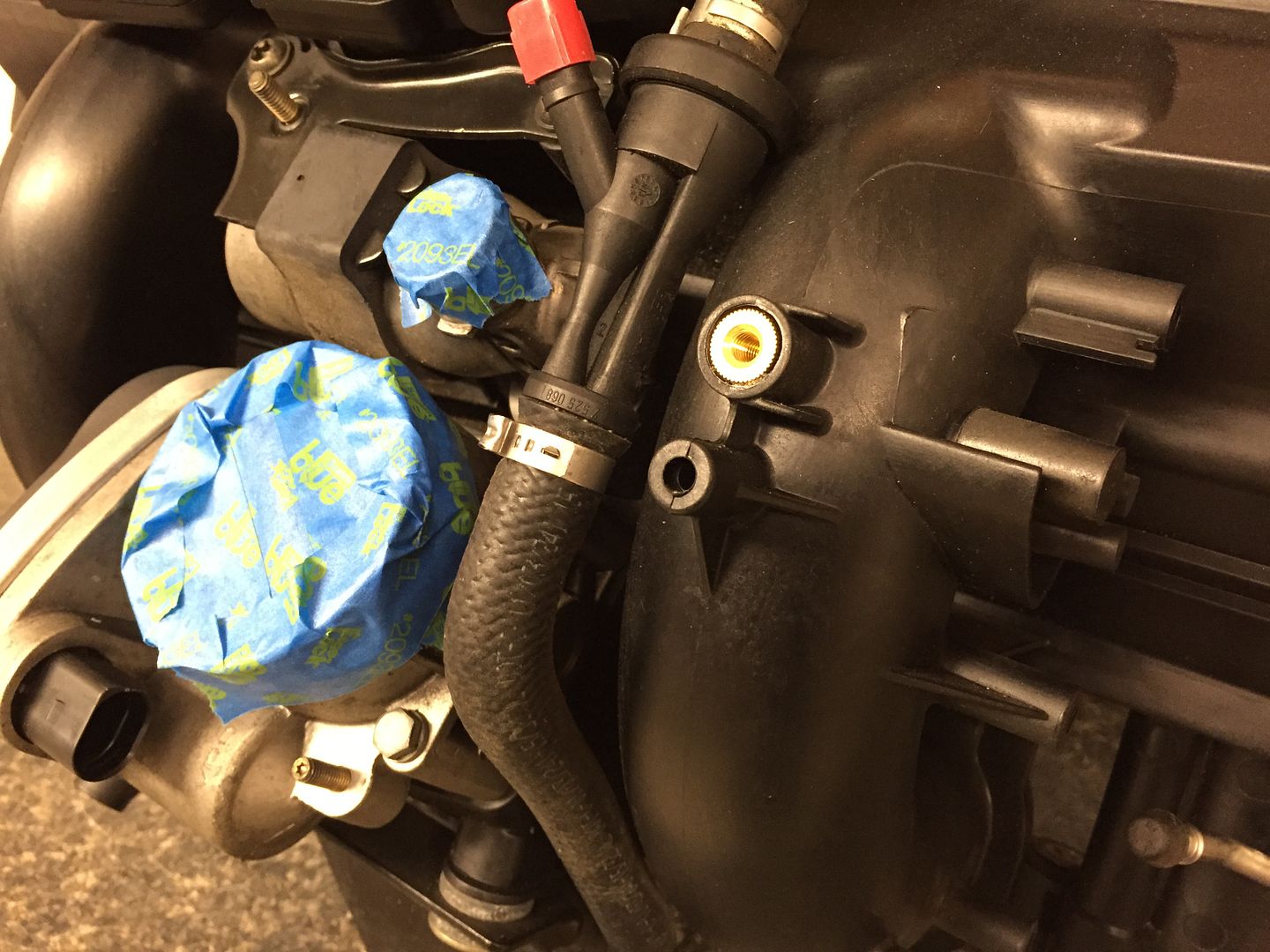

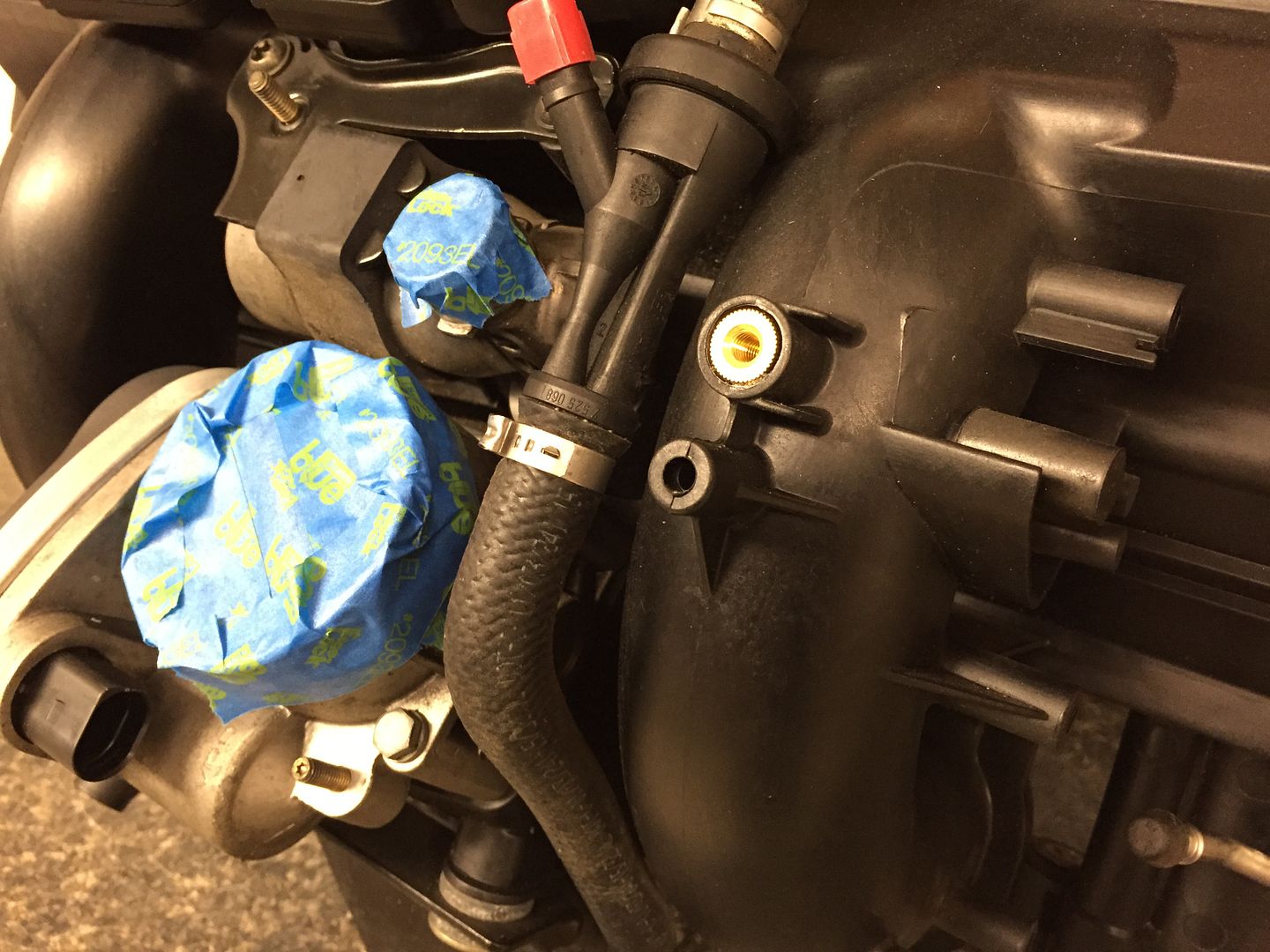

While I was at it I went ahead and modified the intake manifold, shaving off 2 nubs I would not need along with a small part of the vacuum cap wall.

I'll go back and smooth the finish out more once I've finalized everything.

I measured the adapter and found a side to side difference of 3mm, which I would incorporate into the shortened adapter while right side up. I put the adapter in the vice and proceeded to cut it in half and sectioned out a portion of the middle to bring the booster closer to the firewall. I also made sure to mirror the 3mm angle, and actually stepped it up to a 4mm angle in final form.

Booster is pulled back close to 3/4", and angled much closer to the strut tower. As the firewall and or inner structure is also at an angle it becomes a net loss and the booster/master down visually point straight forward.

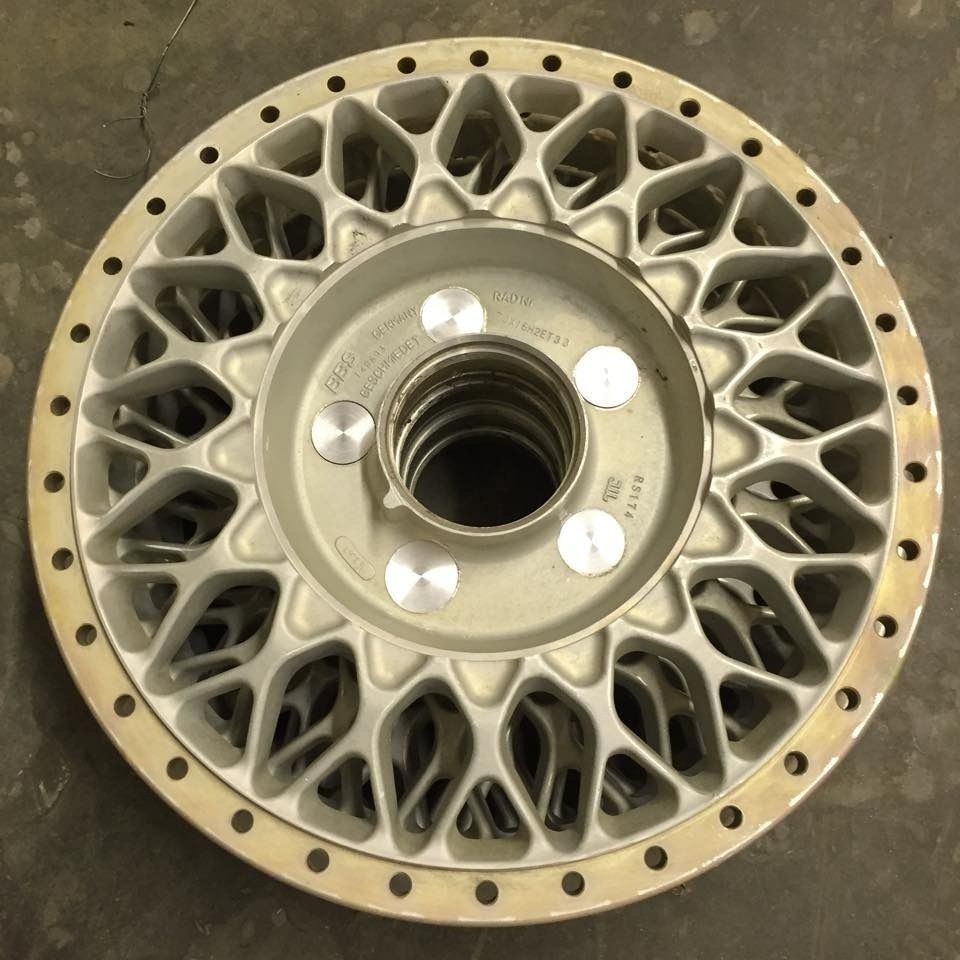

Test fit of the booster, manifold with the adapter taped together:

Clearance of about 1mm. Not much. But its a start. I shortened and angled the adapter as much as possible while still being able to attach a nut to the shortened studs so I'm going to get it TIG welded together tomorrow.

I'd like a little more clearance, so I can either massage the booster a little in that spot, or shim the drivers side engine mount to find that room.

While I was at it I went ahead and modified the intake manifold, shaving off 2 nubs I would not need along with a small part of the vacuum cap wall.

I'll go back and smooth the finish out more once I've finalized everything.

I measured the adapter and found a side to side difference of 3mm, which I would incorporate into the shortened adapter while right side up. I put the adapter in the vice and proceeded to cut it in half and sectioned out a portion of the middle to bring the booster closer to the firewall. I also made sure to mirror the 3mm angle, and actually stepped it up to a 4mm angle in final form.

Booster is pulled back close to 3/4", and angled much closer to the strut tower. As the firewall and or inner structure is also at an angle it becomes a net loss and the booster/master down visually point straight forward.

Test fit of the booster, manifold with the adapter taped together:

Clearance of about 1mm. Not much. But its a start. I shortened and angled the adapter as much as possible while still being able to attach a nut to the shortened studs so I'm going to get it TIG welded together tomorrow.

I'd like a little more clearance, so I can either massage the booster a little in that spot, or shim the drivers side engine mount to find that room.

Comment