If you recall, ever since installing my Megasquirt setup, I've been having rich idle issues when the engine bay is heat soaked. One last ditch effort I did was one step colder spark plugs. It seemed like I wouldn't NEED them... but that it wouldn't hurt trying. Surprisingly at my last track day, they might have done the trick! I say might, because we got rained out. But we got in one solid session with a pretty dry track, and I was still pushing the car hard. The idle was perfect pitting in after the session. Before, I would basically have to hold the car at part throttle to keep it from stalling out, it was idling so rich.

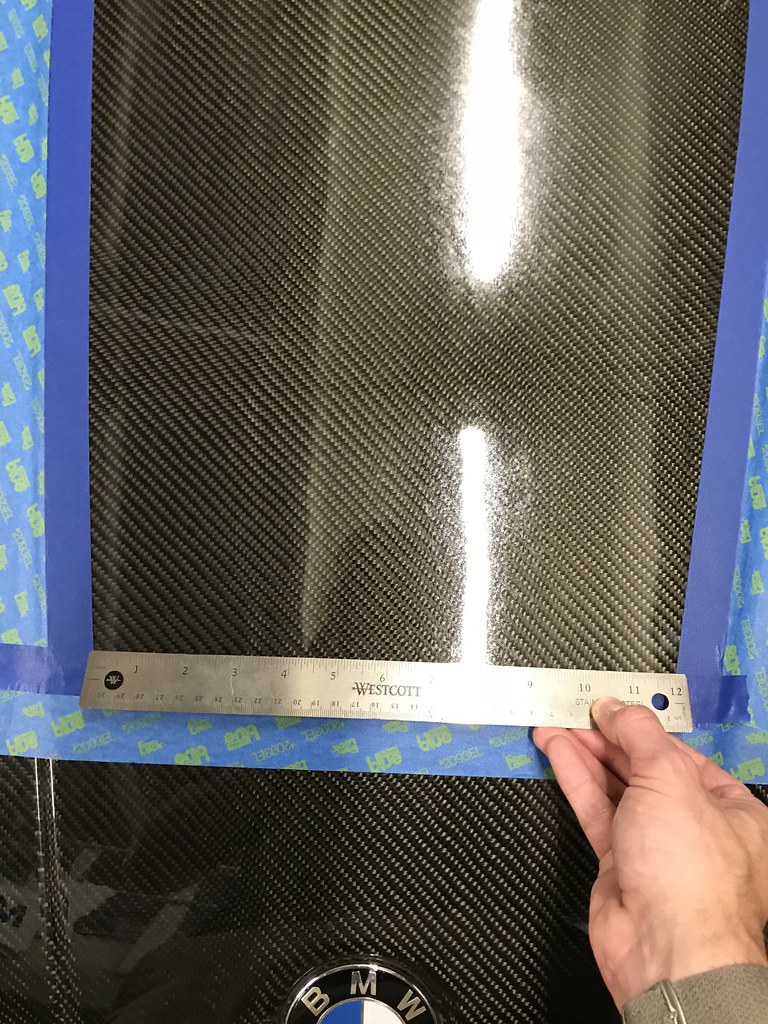

So that's good news. I will report on that again after the next track day in a couple of weeks. In other news, I have been working with Lawrence over at N15 Design (www.n15design.com) to develop a center hood vent specifically for E30s. The design has been finalized, and they are being cut soon. We spent several weeks taking measurements [from my OEM hood and engine bay]. I'm really happy with how the design came out.

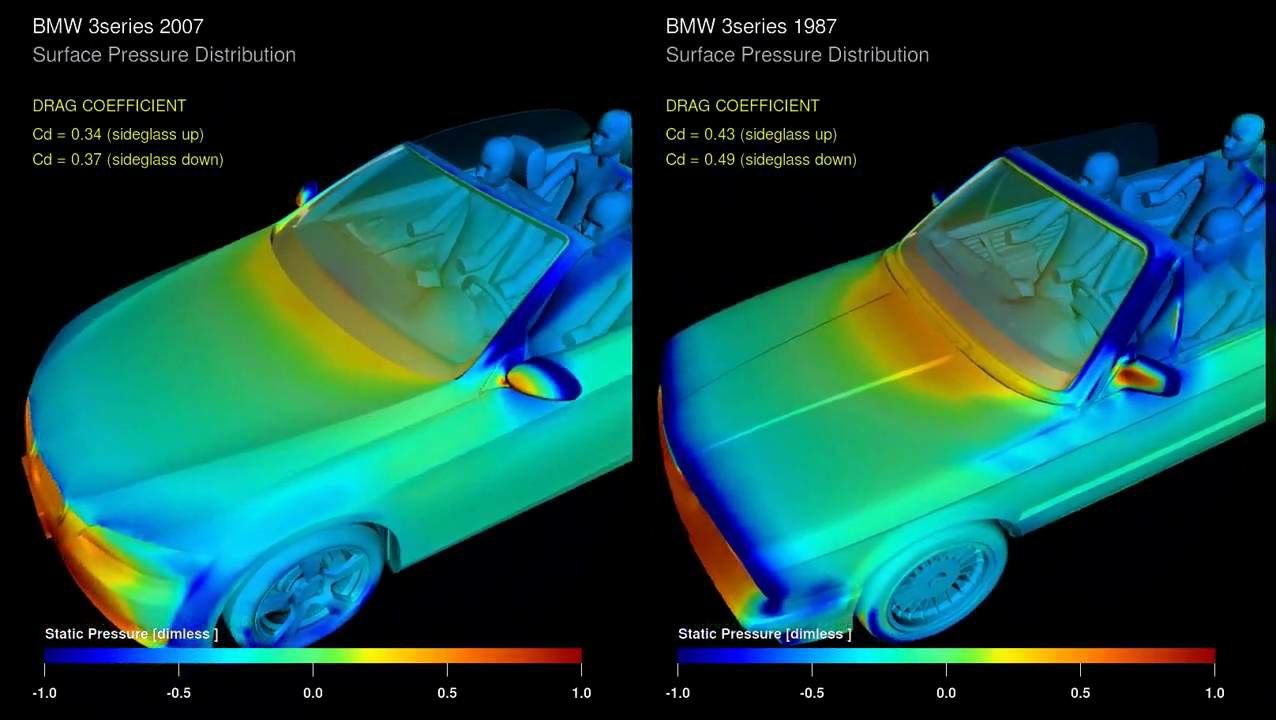

The center vent is about 8" long, a good compromise for 6 cylinder engine bays. It will feature a leading edge gurney flap to kick up the air, and the last slat is recessed so the air can settle back down on the hood. Each individual slat has the same natural arch/curve to it as the hood does. So if you look at it from the nose of the car, the far edges of the slats will not stick up higher than the center does. Little details like this make it very nice! They will be for sale on his site soon for anybody interested.

I will also be installing one of his E36 side vents on the passenger side of my hood, where the headers are. I don't see any need to do the same on the driver's side, as my intake is closed off to the high beam delete. There isn't anything particularly hot on that side of the bay, and I know the center and pass. side vents will make a big difference.

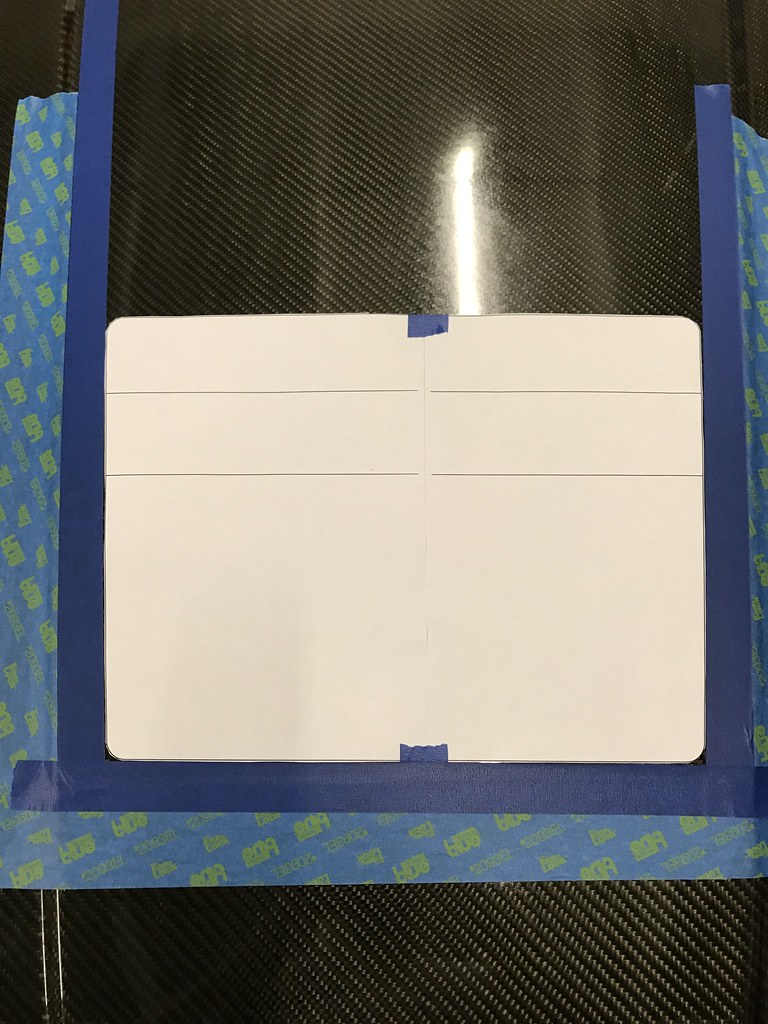

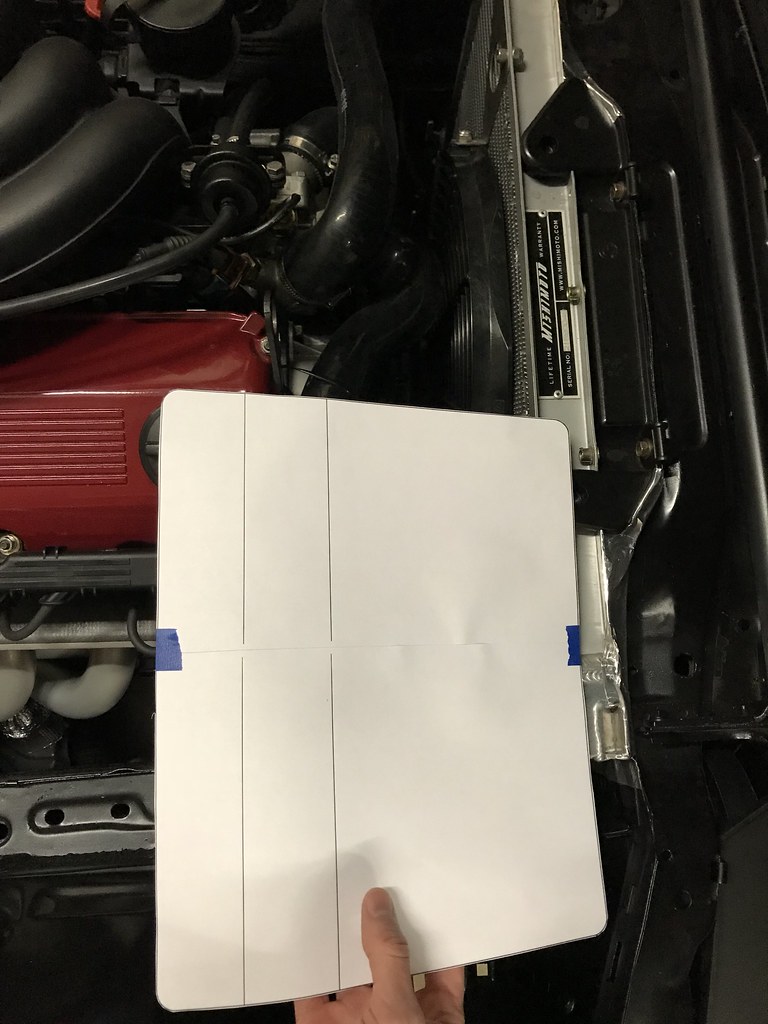

This was the first mock up that included lines at 8", 10", and 12" long. With the coolant sensors, CPS, and injector Home close to the front of an M20, we decided 8" is the way to go.

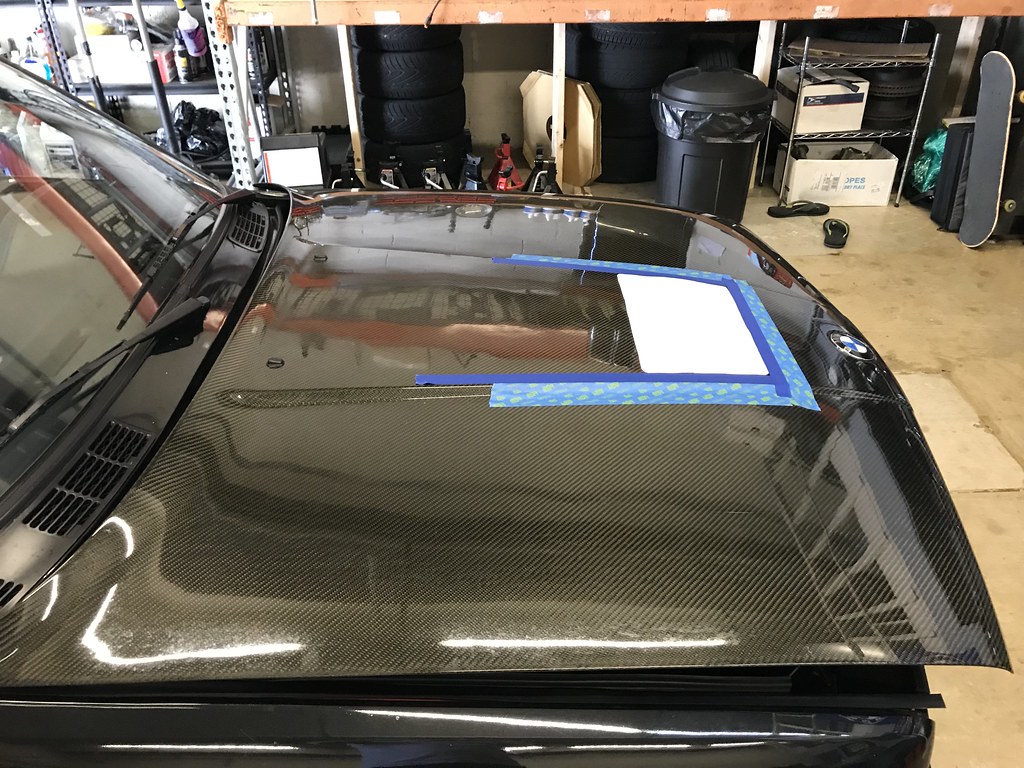

And here is the final size and placement.

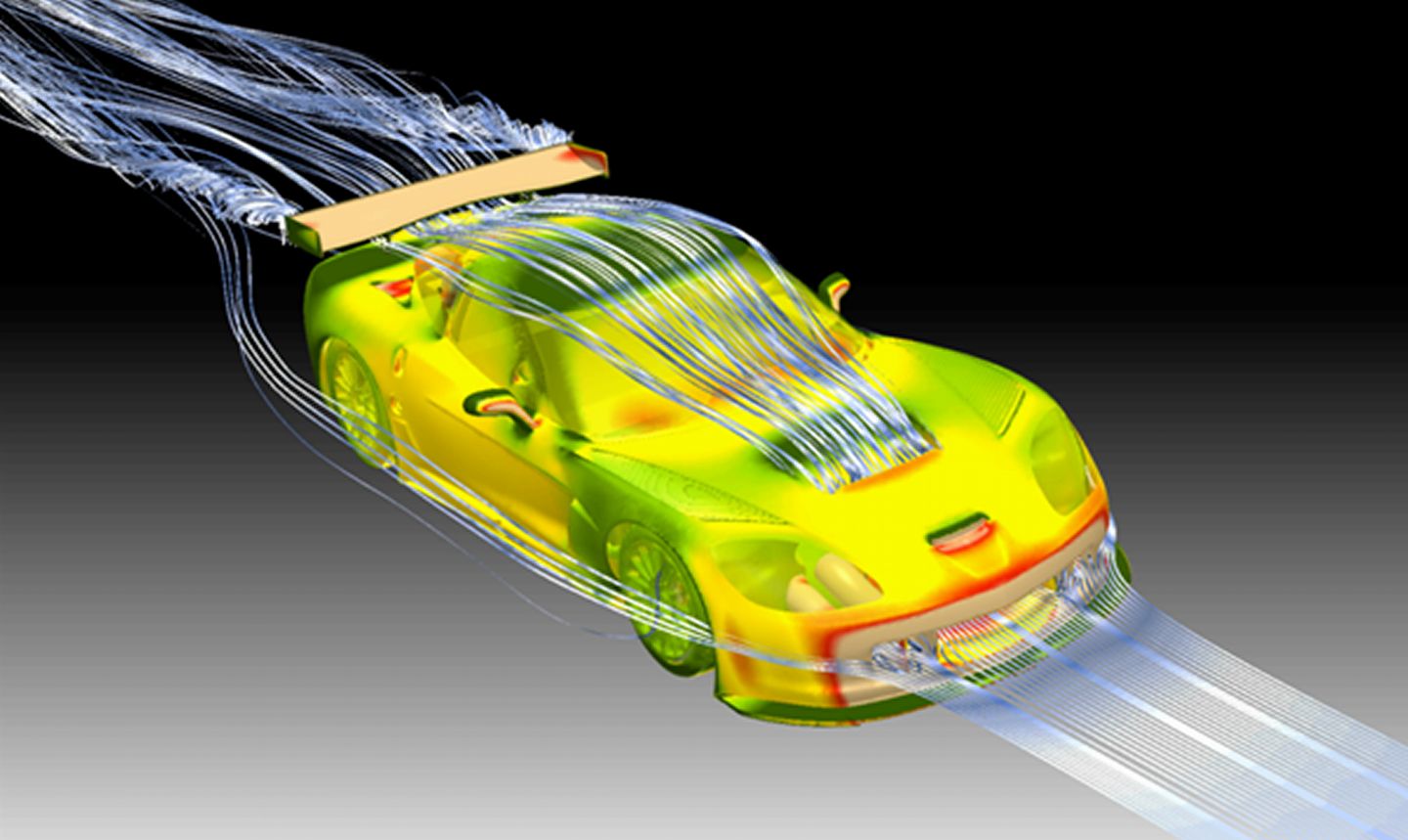

Here is some inspiration I drew from the new Corvette (first pic), and I believe an ATS-V I saw at Cars & Coffee.

Knowing I'd probably have at least some water intrusion up front in the near future, I trimmed up my distributor plastic shroud to reinstall. This was because I have a relocated coil, and I run the single wire up behind the pass. side headlights.

The next project I worked on was making sure my electrical system was up to snuff. I always thought my running voltage was fairly low, usually around 13.4v-13.5v, even after charging the battery. After talking to Greg at Bavarian Restoration, he made some great suggestions that I applied to my car.

The first was to replace all of the fuses in the fuse box with brand new fuses. I always thought it was cool having old school factory BMW fuses in there, but he explained that the corrosion and oxidation on them after 30+ years usually causes some voltage drops. That was a cheap, quick, and easy thing to do.

I then went through every ground and power connector in the bay, and cleaned them up with a scotch bright pad and contact cleaner.

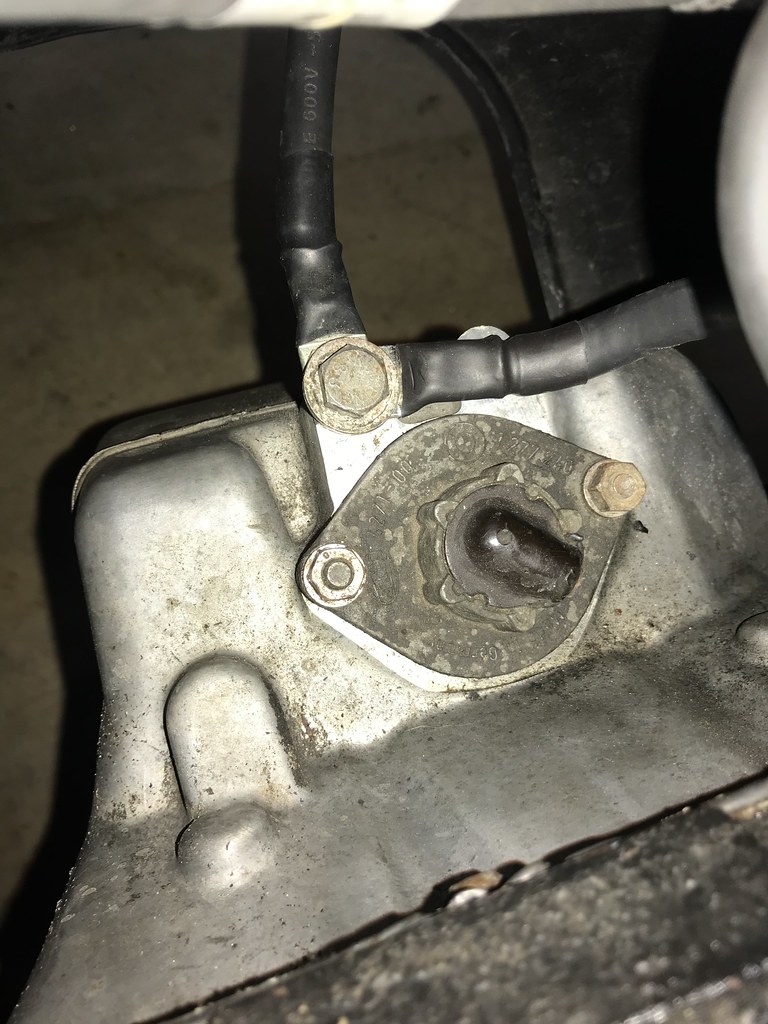

Next up was the alternator. I installed new brushes, which was very quick and easy. I did not realize that the alternator grounded through the case and the mounting point. I had painted my mount when installing this engine. I am sure it was still grounding through the adjusting bracket, but at Greg's recommendation, I installed a dedicated ground cable from the back of the adjustment bolt down to the oil pan, at the same point that the main engine ground attaches.

I also installed one of Greg's mucho nice alternator power cable -- the thick one that runs from the alternator to the starter. Lastly, I cleaned up all the connections on the engine bay power distribution block. They were all pretty nasty.

I then used my multimeter to measure voltages at various points: the Megasquirt board, the injectors, the coil, etc. to make sure they all read accurately (and that Megasquirt was "seeing" proper voltage).

The end result? The first E30 I've seen run at over 14v! I am not consistently getting 13.8-14.1v, which I am quite happy with. It's an original alternator and a battery that is about 5 years old to boot.

Next up I adjusted the fitment of the CF hood. It actually fits MUCH better now. I don't know how I biffed it so bad last time I mounted it up. The hood seal now seals much better, which I think will help with engine bay air extraction, especially once the vents are on. Lastly, I adjusted the rear latches/catches, so that they are tighter. On the track, this GREATLY reduced the cowl shake I was seeing at 120mph.

Some new goodies from Kooglewerks arrived. Hand made aluminum front splitter and rear duckbill spoiler. I am going to have both of them powdercoated black, then both will be mounted and braced with Longacre turnbuckle supports.

The paint under my rear iS lip spoiler was atrocious, and the new spoiler does not fully cover up the footprint from the stock spoiler (although it uses the same bolt holes). I decided to shoot that area with some black spray paint. It's nothing to write home about, but it looks MUCH better than it did, and doesn't stand out like a sore thumb anymore. Also, the stock holes were a little rusty, so I hit them with a wire wheel to clean them up before painting.

And here is the final result after several coats of satin black Rustoleum. It's far from perfect, but it looks so much better!

Got to do a track day this month with my friends Julian and Gerry, as well as Carlos from Condor Speed Shop (in the white M3). We had a good time, but ran cut the day short. I think I need some anti fog for my windscreen. No blower motor. Doh!

The next track day is on May 8th. In June I hope to bring the car up to Sebring (finally). I've got a short list of things to do before hitting the track again:

-- Powdercoat splitter, spoiler, hood vents (black)

-- Install the splitter, spoiler, and turnbuckle supports

-- Cut the hood and install the vents

-- Install thinner spring pads (or remove completely) in the rear. The car has too much rake

-- Bleed the brakes

-- Rotate the tires

-- Do a once over on the suspension, brakes, etc. for safety

-- Touch up the tune in cruise a little bit. There are a couple of minor lean spots in transitions.

Leave a comment: