I have done a couple of track days, which were a blast. Finally got down to a new personal best time at PBIR (1:34.90).

It's pretty hard to "read" spark plugs, but my stock Bosch Super's were looking pretty baked for being brand new. I switched to one step colder NGK's. Didn't notice any difference, but I am going to run them for a bit and see how they look.

I cleaned all the contacts and reseated the pins on my ICV wiring. Pulling back the rubber gasket, I was surprised there was moisture or oil in there. Weird.

I remembered by chance that when I originally lengthened the wiring for my tucked ignition coil, I did not continue using shielded wiring on the wire from the ECU to the coil. I wanted to re-do that, so I removed as much as I could of the stock shielded wire from my spare engine harness.

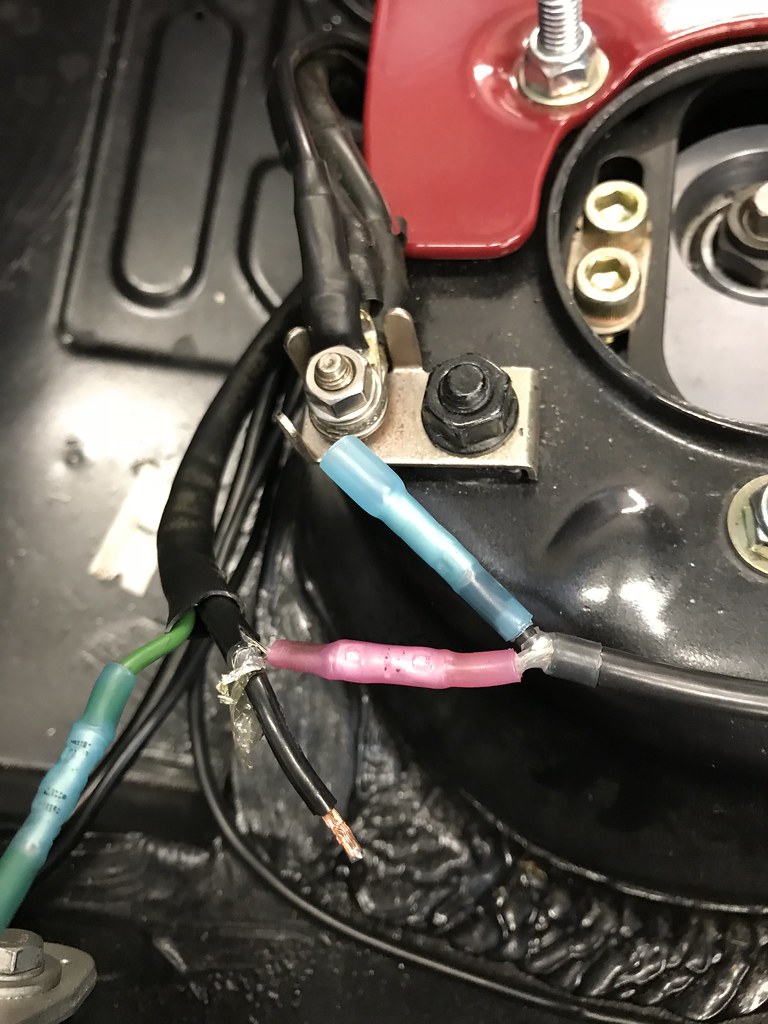

This is how I had originally extended it, soldered with normal copper wire.

Made brand new eyelets for the coil using the OEM method, both crimped and soldered. The original eyelets were corroded.

First step is to join the shielding, being extra careful that none of the grounded shielding strands mix with the power cable.

Then join the power cable separately, wrap in foil, electrical tape the whole thing. Then I finished the rest of the harness with TESA cloth tape.

I bought a new SI board, as mine was causing several issues on the cluster. Sure enough, the one I pulled out had some bad traces from somebody using the long trim screws in the wrong place. The board from ProgRama appeared to be brand new, not a remanufactured original board. It was very nice, easy to install, and worked perfectly.

A new project I've started on is cleaning up all my grounds in the car. I also replaced all of the factory ~30 year old fuses with brand new fuses. I am trying to get the voltage system up to snuff. Next up is a new alternator cable and a dedicated ground cable for the alternator from Bavarian Restoration. I didn't realize that the alternator grounds through it's mount, and I spray painted it, LOL. I am going to run a ground cable from the case to the oil pan, and replace the brushes/voltage regulator on my alternator.

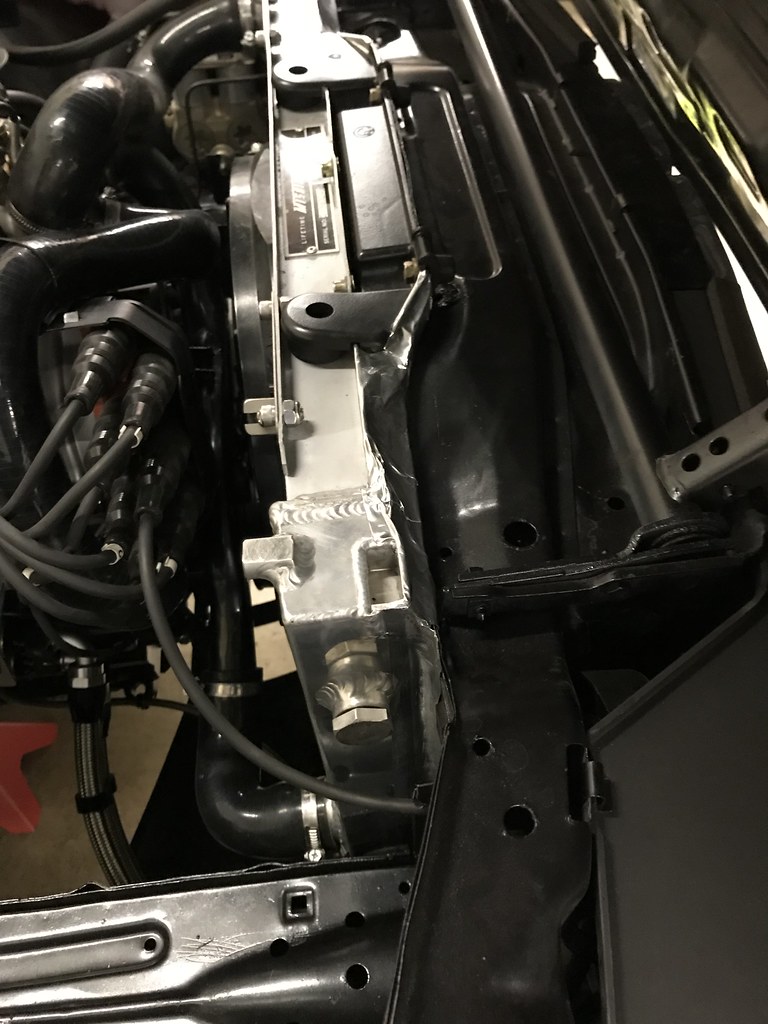

I've also been working on engine bay cooling. It gets quite hot on there, even with the ceramic coated headers. The first thing I did was tape up the gaps around the radiator with DEI aluminum tape. This stuff grips well and doesn't show any signs of loosening up yet.

On the track, I did not see any appreciable difference in temperatures, but it did not hurt. I also experimented with removing my hood seal on the track. You could tell the difference in wind noise at 100+ mph, and the wiper blades were getting pushed up, but again, no noticeable difference in temperatures.

I am thinking about drilling holes in my front bumper (a la Sherpaking) and core to get more flow to the radiator, and also considering adding a vent to the front-center of my hood (like Trent did back in the day).

And as usual, here are a couple parting shots of the car on the track:

Leave a comment: