Got the rear subframe pretty much completely assembled, starting with the parking brakes:

Pressed the hub in using the old tricks (I'm telling you that Astro kit was invaluable):

Rotors, pads, and calipers in, and adjusted the parking brake per the Bentley:

Had tried a few days earlier to tap the half shafts into the hubs but I had to hit them a little harder than I liked and didn't make a ton of progress. Ended up picking up this kit which has been mentioned in various DIY's that proved to work as well as advertised:

Pretty self explanatory, you get the half shaft spines aligned with the hub and tap it on just enough to get it started. I lubed the splines with some liquimoly LM508 antiseize. You then thread the tool onto the half shaft thread and then tighten, I could almost do it with just my hand it worked so easily:

All done:

Almost a shame to buy something and then use it for all of about 30 seconds, but it definitely saved me a nice chunk of time and potential damage to the half shafts.

I was going to just mount the dif as well until I realized how damn heavy that would be to pick back up off the work table. I'll end up getting the complete subframe under the car and get the diff on a jack, mount it all up and lift into place when I'm ready for it.

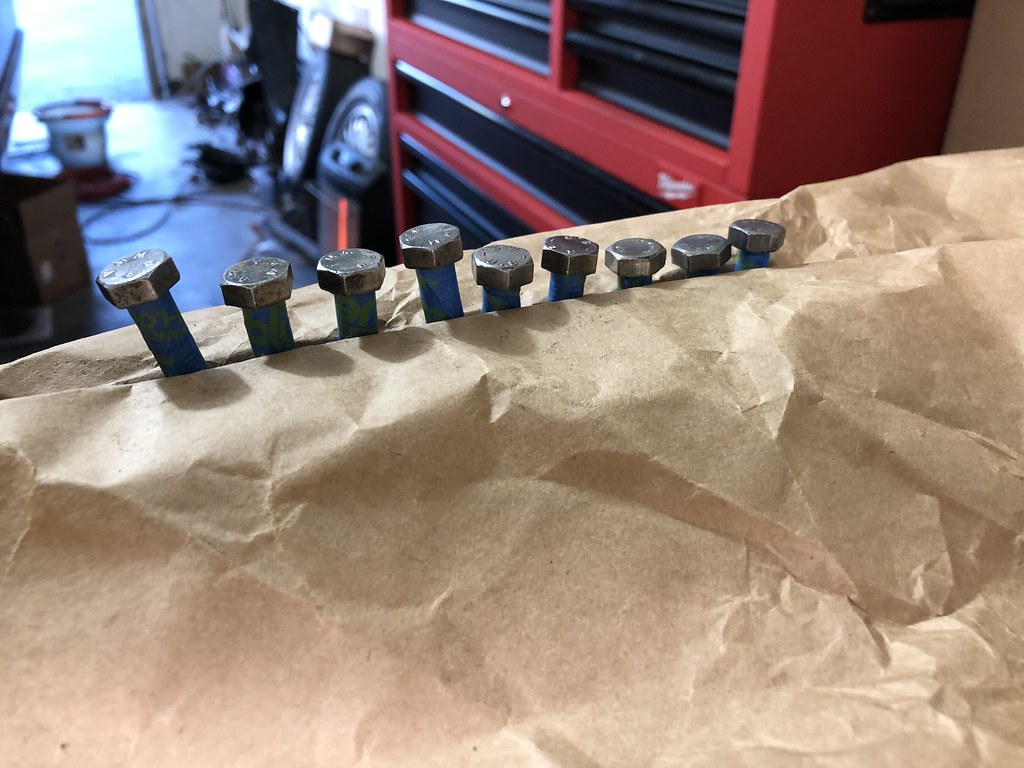

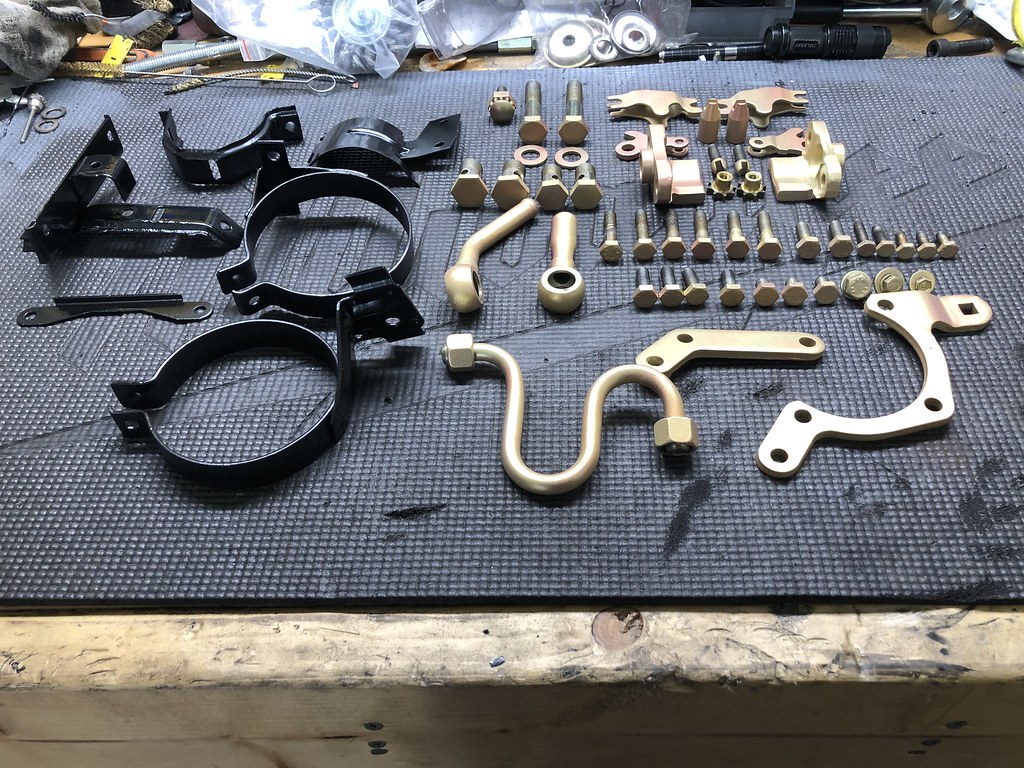

I started on the front strut tubes and was flying along. Got the dust shields and hubs pressed on in no time. Thought I'd pause for some shots with my sparkly new goodies, that hubris must have got me...

The left strut slid in no problem, I hand tightened the gland nut then went to slide the strut into the right strut tube...

and only made it in this far:

I immediately knew the tube must be bent. Sure enough:

Ever so slight of a bend, but the tube won't go in. It's barely noticeable but I wish I had caught it sooner. I'm more pissed about all the prep work to get the damn thing painted, now I'll either have to refinish mine or buy another and risk the same thing happening. I contacted the guy on ebay I bought it from and he's sending a replacement, so we'll see.

Then I remembered I have to get the front hub back off without ruining it or else this would really be an expensive screw up. It came off no problem but obviously the inner race and ball bearings stayed behind. I got the race off very gently so as not to mess it up and it came off just fine. I put it all back together and it seems to still spin smoothly:

I don't think there's a reason not to use it, the race basically came off and I popped it back on without issue. Any apprehension to using it? What do you guys think???

Dammit, I was almost going to be able to get at least some of this stuff mounted back up today. C'est la vie.

Leave a comment: