Got the muffler installed, it looks pretty damn good!

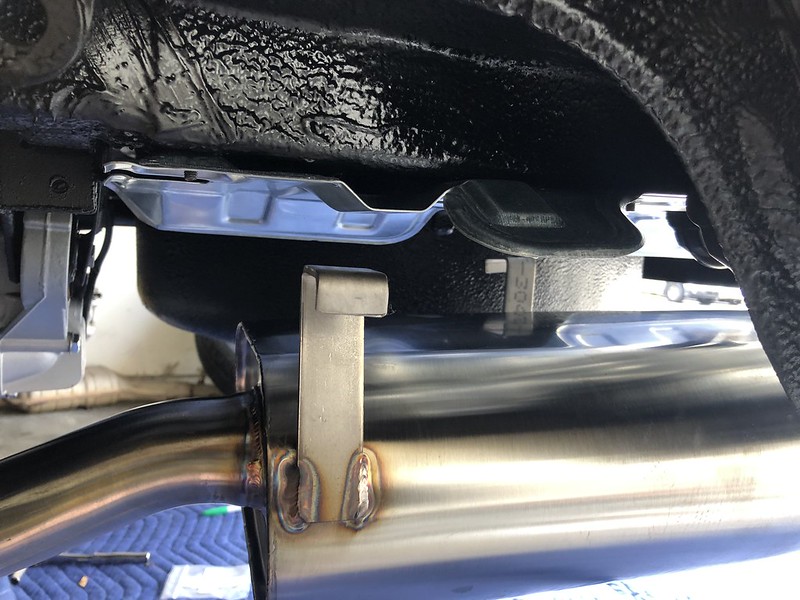

My OCD is much happier with the uncut heat shield:

Can't notice the old hanger position much, and definitely not with the wheels on:

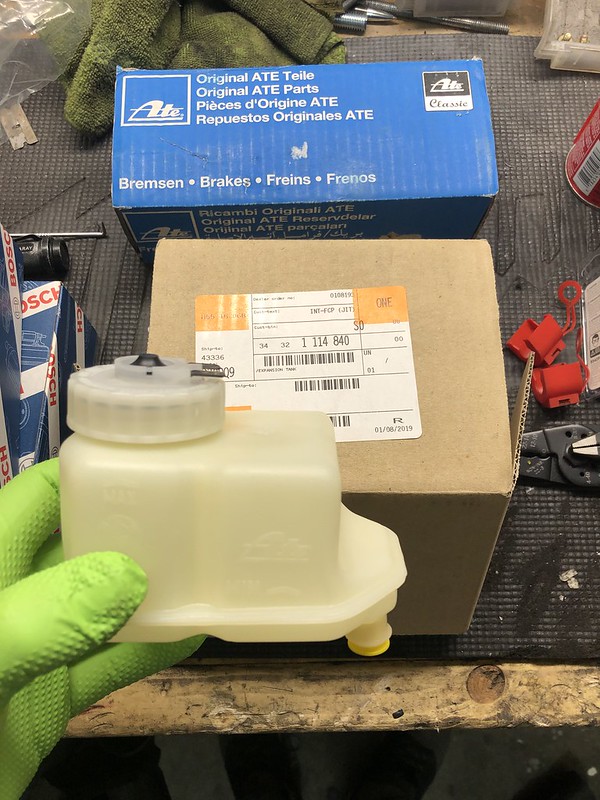

Next I had to finish up the remainder of the brakes, starting with about the most unexciting $300 you can spend on your car:

Needed to be done though, the old ABS sensors were crumbling

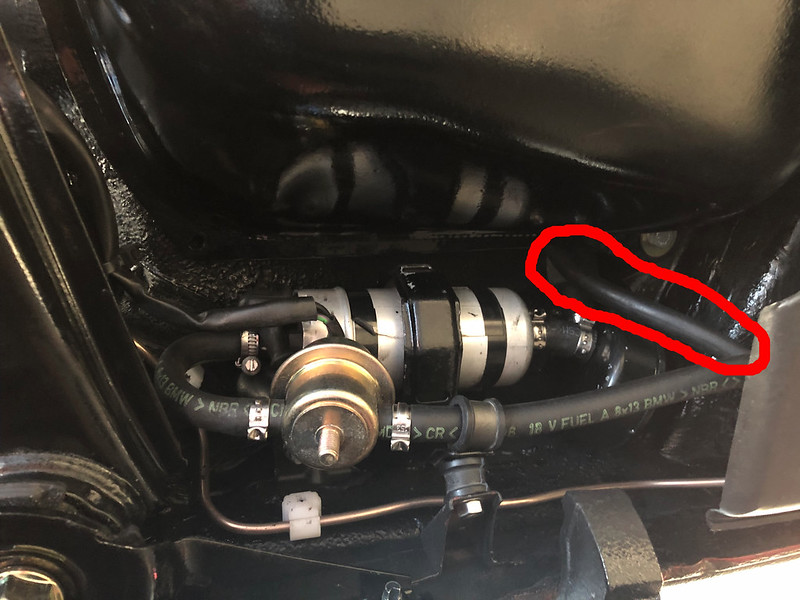

Also realized my front brake pad sensor harness was missing the ground ring so crimped on a new one:

Not too far behind in the expensive yet yawn-worthy parts:

Bought a brake master cylinder bleed kit only to find out that the MC I bought came with one:

Removing all the bubbles:

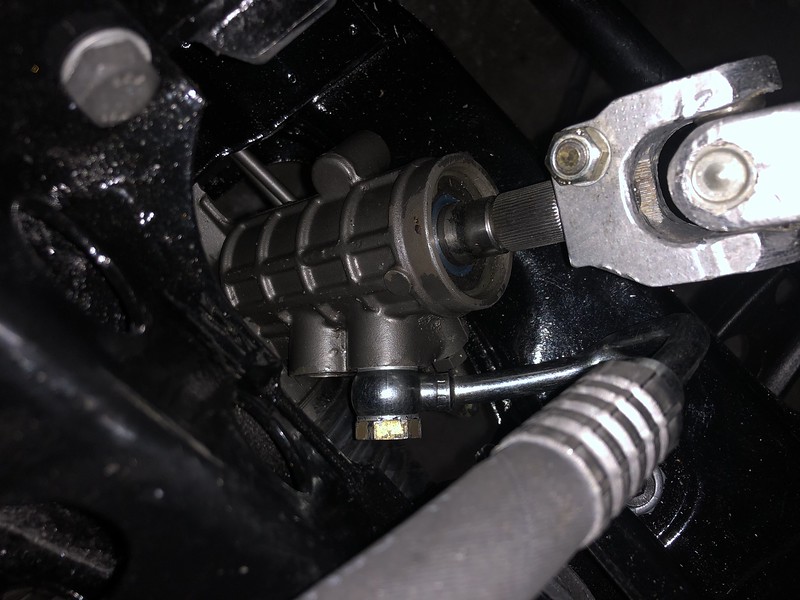

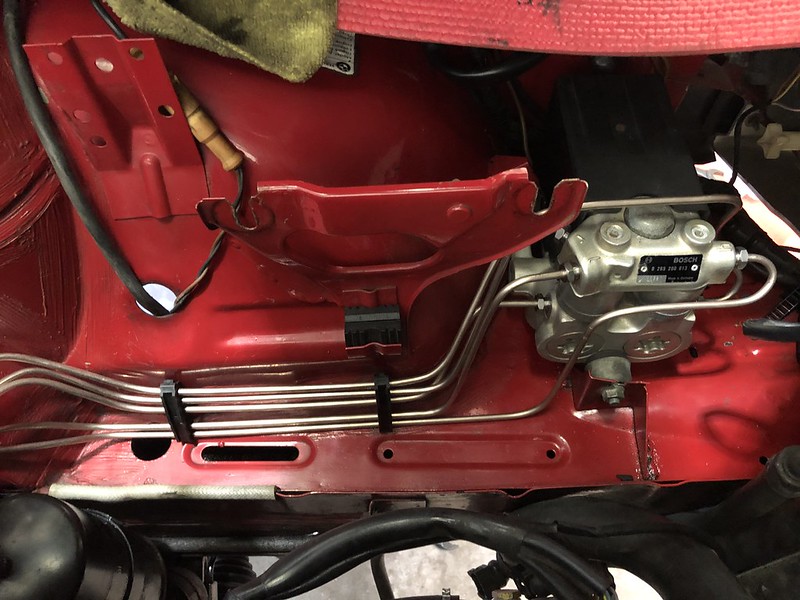

Got the MC installed and all the remaining hard lines hooked up. Now came time to bleed the system, including the ABS pump.

Since I previously removed, cleaned, and pumped the ABS pump full of compressed air I wanted to do a thorough job of flushing the ABS module. I found this thread which was helpful:

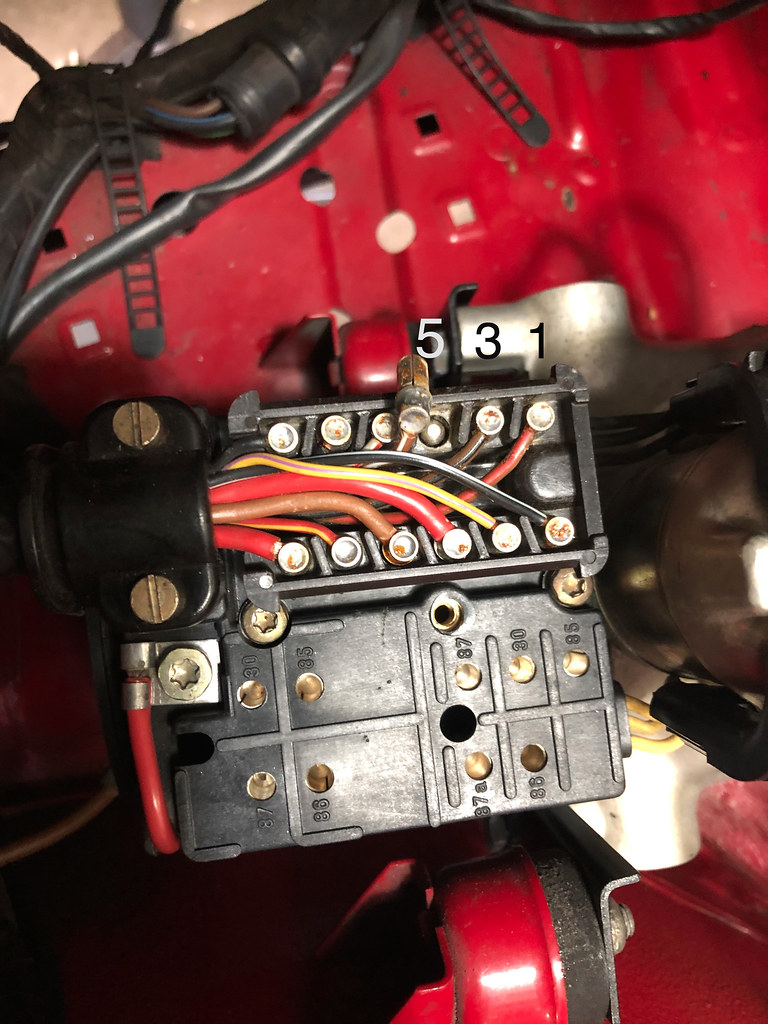

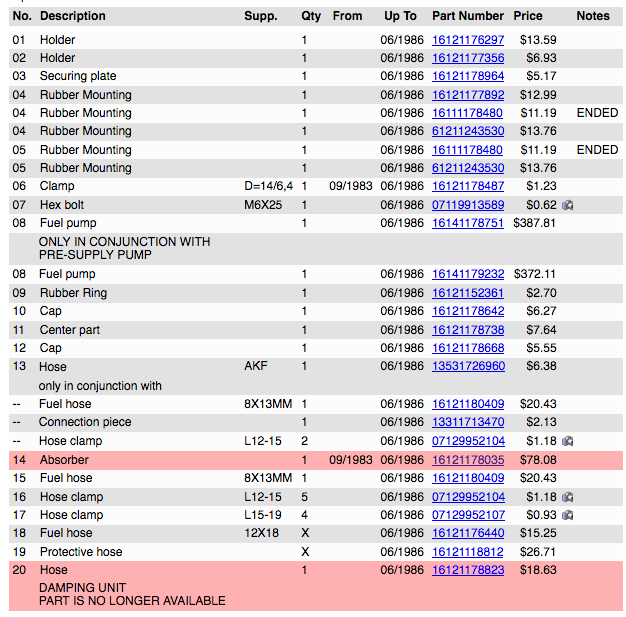

So I removed the cover and the two relays on the ABS module as well as the plastic cover for the harness plug. As you can read in the above mentioned thread, the pin positions you need to worry about are pins 87 and 30 from the relay on the left, 87 and 30 from the relay on the right, and pin positions 1, 3, and 5 from the harness plug.

The harness plug pins are individually removable using some small needle nose pliers as you'll notice here with pin 5:

- Pins 87 and 30 from the left relay supply power to the ABS pump itself.

- Pins 87 and 30 from the right relay supply power to the solenoid valves of the ABS module that open and close to selectively provide pressure to the different brake calipers

- Position 5 on the harness plug supplies the rear caliper solenoid, one solenoid for BOTH rear brakes

- Position 3 on the harness plug supplies the passenger front caliper solenoid

- Position 1 on the harness plug supplies the driver front caliper solenoid.

What you'll need to do is jumper pin 87 and 30 on the left to run the ABS pump. Keep only one of the pins plugged in until you are ready to actually bleed to prevent the ABS pump from running too long.

Jumper pins 87 and 30 on the right relay to get power to the solenoids. Using a remote starter switch (purchased for $15 at Advance Auto), you'll need to attach one end of the starter switch to the individual solenoid pins (Positions 5, 3, and 1 on the harness plug) and the other end to ground, I used one of the strut mount bolts.

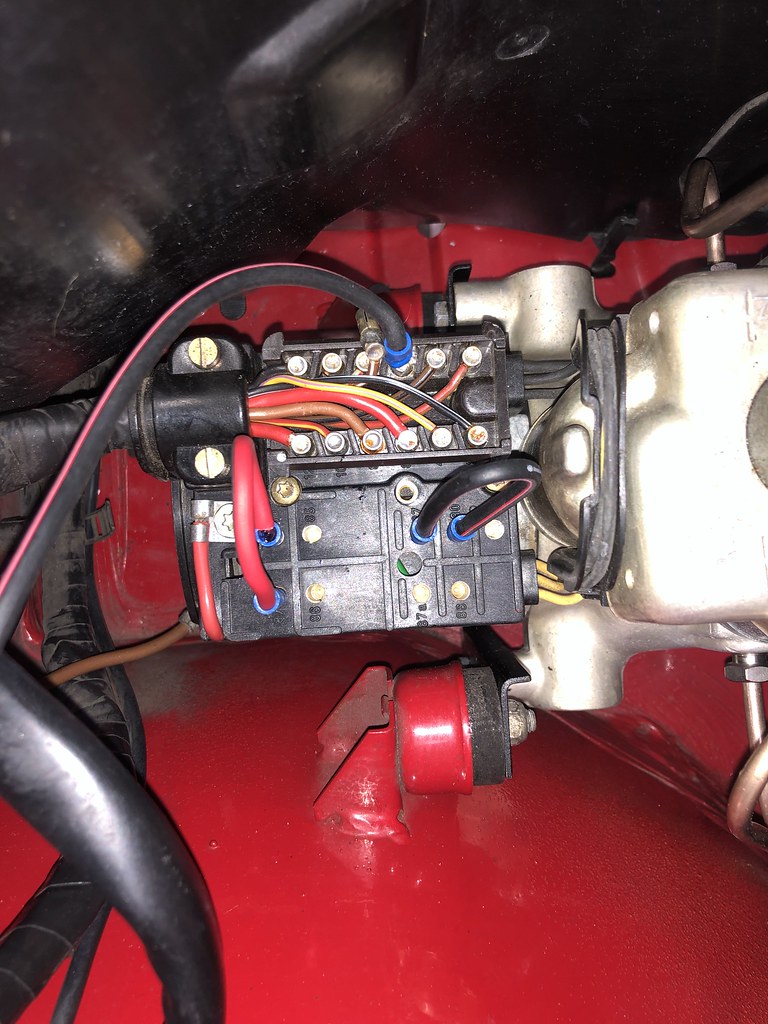

Here's the setup I used:

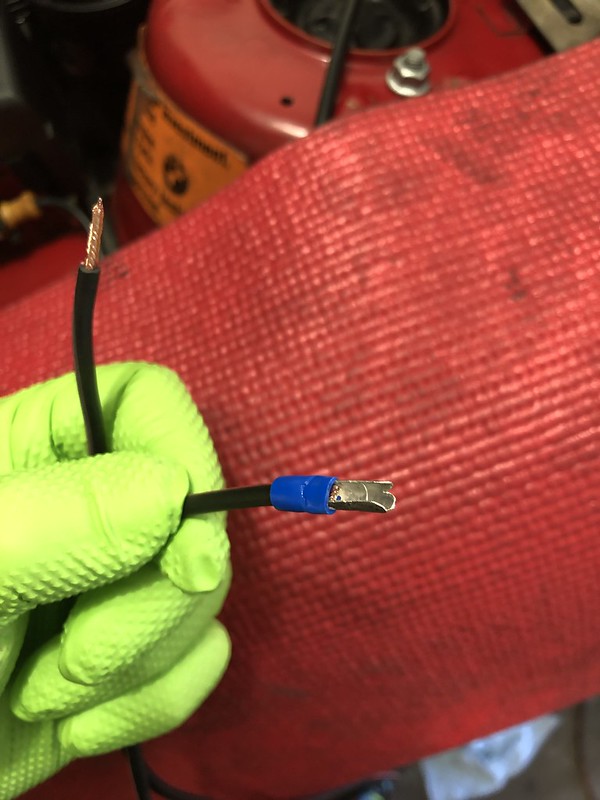

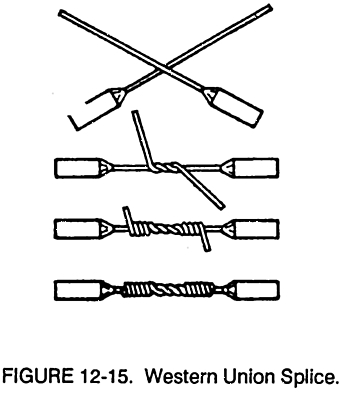

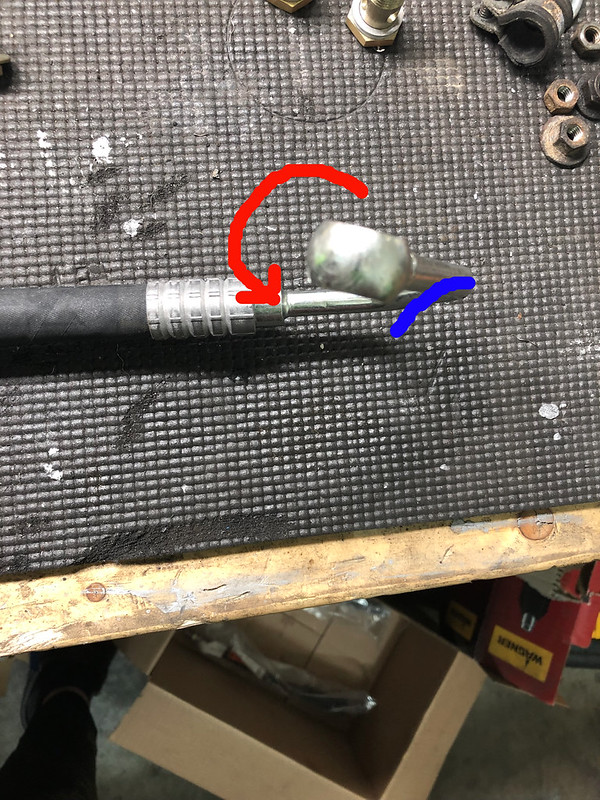

In order to connect the starter switch to the individual solenoid pins, I rigged up a "female" adapter from the male bullet plugs on the other jumpers:

I used a fairly long length of wire for this as you'll need to be sitting in the driver's seat while cycling the solenoid valves.

As I said before keep one of the jumpers for the relay on the left unplugged until ready to start bleeding otherwise your ABS pump will be running the whole time.

Get your pressure bleeder hooked up, one end of the starter switch grounded on the strut screw:

And the other end attached to the long wire that is plugged into solenoid position 5 (rear wheel solenoid) on the harness plug:

So for the individual solenoids, it will correspond to the proper way of bleeding the brakes: Passenger rear, driver rear (solenoid position 5), Passenger front (solenoid position 3), and finally driver front (solenoid position 1).

At the start, you should have:

Right ABS relay positions 87 and 30 jumpered

Starter switch connected to pin 5 and to ground

Left ABS relay HALF jumpered (remove either the end in pin 87 or 30, it doesn't matter which).

Make sure to fill the pressure bleeder with plenty of fluid as you'll go through a fair amount. I filled it with two liters of brake fluid and was getting pretty low by the end of the whole process.

Start by bleeding the passenger rear caliper until the line is essentially free of air. You want enough fluid to drain into the catch can until the drain hose is submerged to prevent air from re-entering. Once you're happy, put your key in the ignition and turn to position 2 (but don't start the car). Now, plug in the free end of the left relay jumper, you should hear your ABS pump turn on. Now, get in the car, and slowly depress the brake pedal while flipping the starter switch, you can hear the solenoid click on and off as you flip the switch. Flip the switch rapidly as you depress the pedal, you can actually feel it in the pedal as the solenoid opens and closes. As you release the brake pedal, release the trigger on the switch and slowly allow the pedal to return to the starting position. Do this 5 or so times. Now go back and check on you caliper and ensure no further air is coming out. When satisfied, turn the ignition switch off, unjumper the jumper to the ABS pump, and close the bleeder valve on the caliper.

Move on to the driver rear caliper and do the same, keeping the starter switch connected to pin 5 (this solenoid controls both rear calipers).

Then move on to the passenger front, and now connect the starter switch to position 3.

Then move on the driver front, starter switch to position 1, you get the idea.

As the pump turns on, you can actually see some air coming into the system that had previously been absent when just bleeding the caliper. I was happy with the results, we'll see how the brakes feel upon driving.

Last project of the day, got all the wheel hub collar nuts torqued with new lock plates and covers:

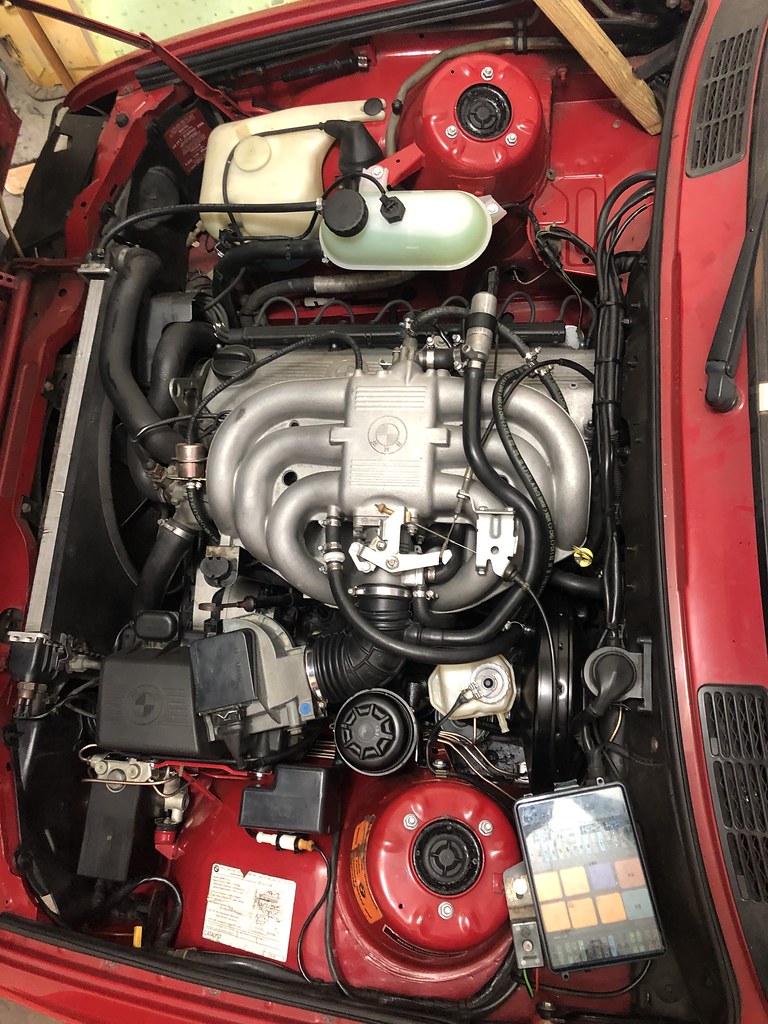

Got the engine bay cleaned up, amazing what some new plastic parts can do for the look of things. Also awesome to actually be able to see the fluid level in the coolant expansion tank:

Filled the PS reservoir with new LiqiuMoly ATF fluid. Waiting on some decals from Pukar Designs to complete the engine bay.

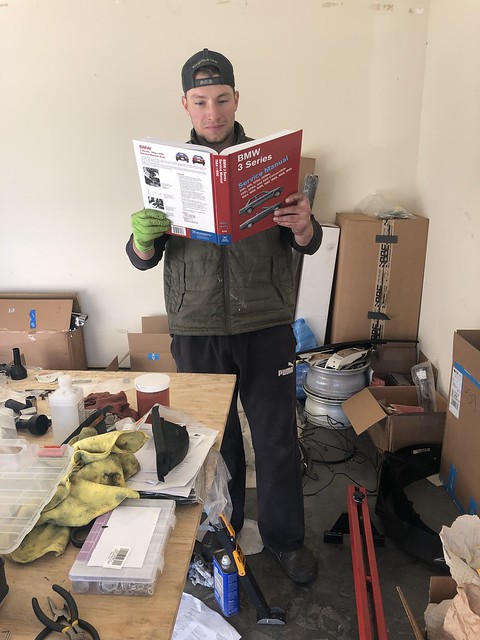

Last I ended up mounting and torquing the tires, and torqued all the swaybar connections per the Bentley with the car on the ground. Unfortunately, I misread one of the torque values for the rear swaybar link to trailing arm (Supposed to be 16 ft/lb, ended up torquing to 30ft/lb as the rest of the bolts were all 30) and snapped the bracket bolt off. Those rear trailing arm brackets are currently back ordered everywhere, and I threw my old rusted one away. If anyone has an extra (preferably new) laying around I'd be very interested.

I couldn't help myself but throw a couple gallons of gas in there and start her up. Took about 3-4 turns for the fuel to pump through and... she ran!!! Had some surging idle that I'll now have to track down (again, ugh) but the exhaust sounded good. My battery had died by the time I tried to start it up again today after work to try and sort thing out. It wouldn't hold a charge when I tried to jump it so I'm stuck until I can go get another one on Wednesday. Stay tuned...

Leave a comment: