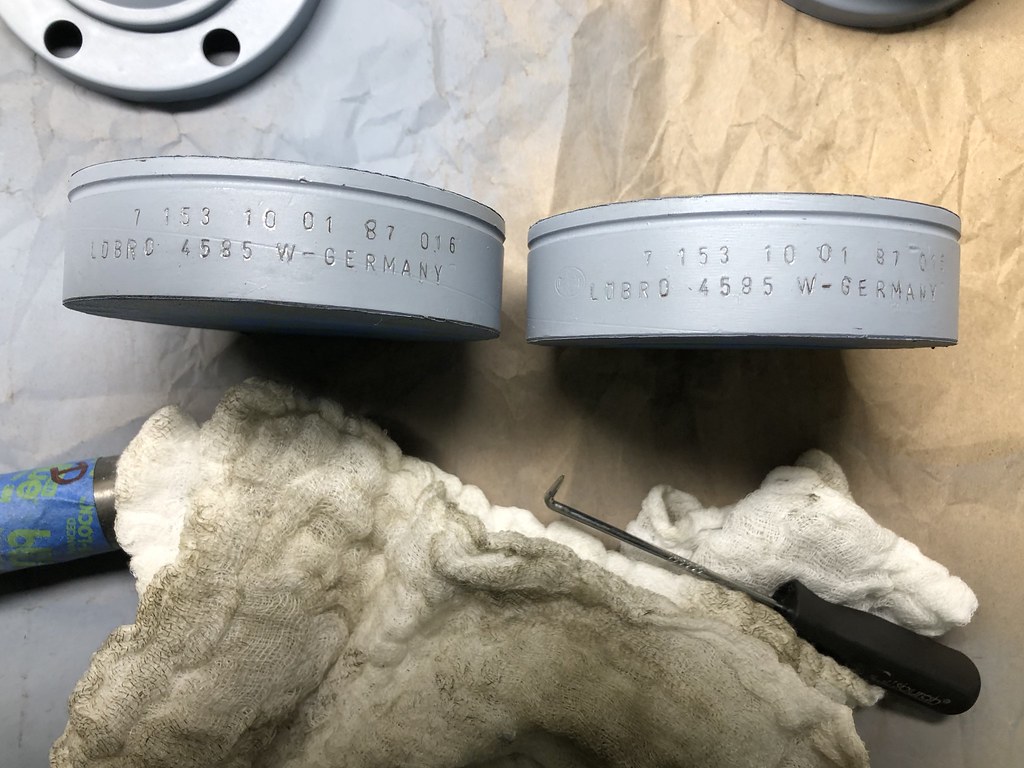

Re-sealed the diff with Permatex Ultra:

I had a paper gasket as well but decided to forego it after a bunch of reading. If it ends up leaking I can always use it.

Hand tightened the nuts and got a nice bead to squeeze out all around, then waited an hour to torque down.

I waited til the next day to fill it with Redline 75w90. Also replaced the speed sensor, the longer end goes towards the outside of the diff. When you put the securing plate back on you'll see it can only go on one way. Also, don't forget the speed sensor O-ring:

It was easier to put the O-ring in the hole first and slide the sensor in than to seat it on the sensor and try to get it on:

Flat side of the sensor aligns with the flat part of the lock plate:

Not quite Jordan level sparkly, but looks really good. I didn't have a 3.25lsd tag, if anyone has one lemme know.

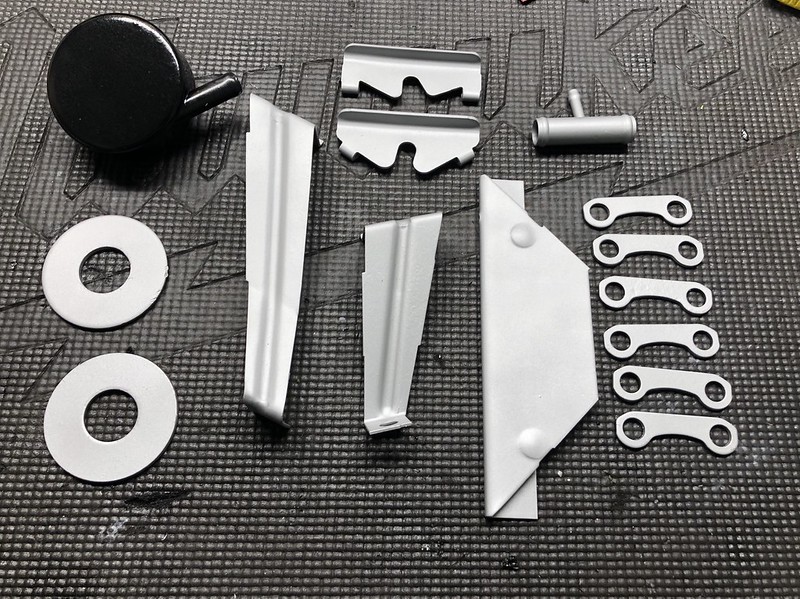

Also got to work refinishing some random hardware, still have a box full of stuff to get done before reassembly:

Fuel tank mounting brackets before and after cleaning:

And after paint:

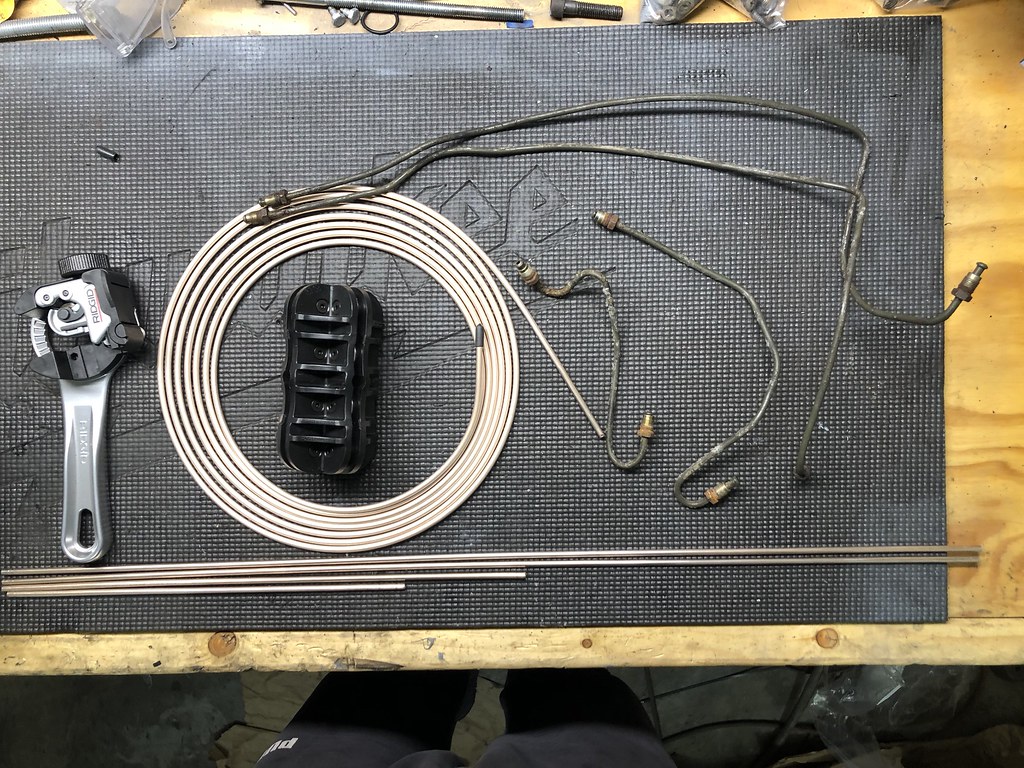

Also got to work bending my new hard brake lines. I found this article helpful:

I ended up using Cu/Ni brake line. It was really easy to work with and made really good bubble flares. It's also supposed the be the most corrosion resistant, which judging by my old lines was the main goal. I bought the Eastwood flare tool as well as the line straightener, they were a little pricey but made life easy. I ended up buying a total of 25 feet of line and still had a few feet left over. You'll also need a total of 10 3/16" 10x1mm bubble flare fittings.

I was really happy with how they turned out. For the main line that runs the length of the car and connects the front to the rear T-connector, it was a little unwieldy to work with (120 inches of line in a tight rental garage was a stretch) and became hard to make the bends in the correct 3-D orientation. I'd make the correct bend in 2D left-to-right, but then the orientation would be off front to back. If you ever have to do it you'll see what I mean. I ended up taping the old line to the new and used that as a template to keep everything together and it worked well.

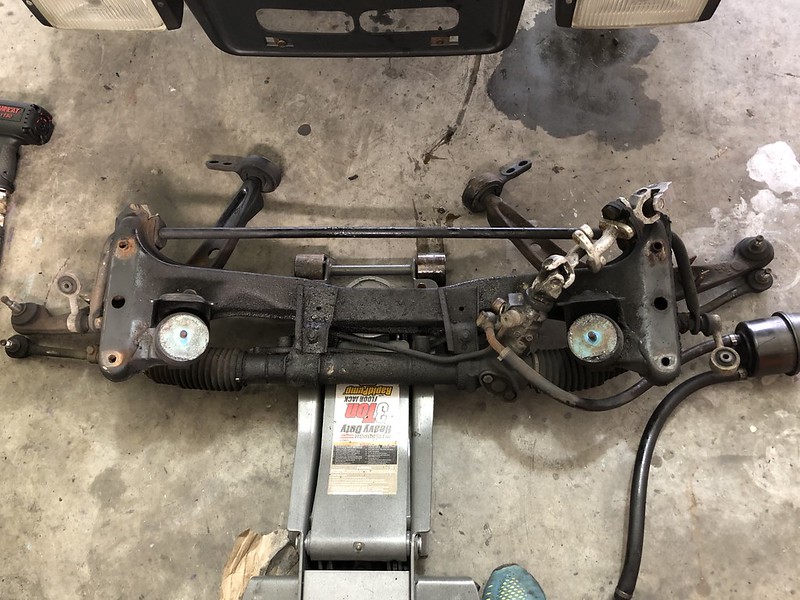

I also got all my subframe/trailing arm bushings pressed in as well as the rear wheel bearings. All pretty much set to go back in once I get the dust shields painted, waiting on cleaning a few other parts so I can paint a bunch of stuff all in one shot:

I need to start reassembling soon, my (other) pride and joy is slowly getting squeezed out of the garage:

Last, I took out the power steering pump and dropped the front subframe with the intent of also doing the oil pain gasket while it was off:

Got everything disassembled:

Then got everything that will be reused degreased and ready for paint.

Next I went to work on getting the oil pan out and hit a snag:

That little e10 Torx bolt tucked way up behind all the autotragic coolant lines stripped. It was the last of 8 bolts to get the transmission reinforcement bracket off. Couldn't have been one of the other 7 completely accessible bolts, had to be the one tucked way the f*** back up there. I did everything I could to make sure the socket was seated all the way in, but with all the coolant lines in the way I must not have been all the way on. I tried an extractor but I need to tap it on to get it fully seated and just don't have the room to get a hammer in there. UGHHHHHHHH I was and still am PISSED. WTF. I could have had the oil pan out, cleaned, and resealed 10 times over in the time it took me to mess around trying to get that bolt off.

With the trans lines out of the way and if I remove the mounts and drop the angle of the trans down a bit it wouldn't be tough to get to. I didn't want to have to remove all the lines and thus the transmission fluid, especially with a 5-speed swap planned. I guess I'll just have to wait until I do the swap and take down the front subframe again, which I didn't want to have to do. Removing the subframe actually wasn't all that bad, so oh well. Unless someone has any other suggestions, I'll just hold tight on the oil pan until then, not the biggest deal in the world.

Happy New Year!

Leave a comment: