Henneman was the manufacturer. They made CF and fiberglass. CF tended to shrink a bit and fit was not as perfect as FG.

My 2002's resurrection - 56k go die

Collapse

X

-

Brake harder. Go faster. No shit.

massivebrakes.com

http://www.facebook.com/pages/Massiv...78417442267056

-

O rly Lee. One way or another, there's a couple options then if the link I gave isnt the exact original manufacturer that made these for the FAQ. Thanks for the insight though :) I just found that link I gave earlier on the FAQ, I thought it was right. Either way, they're roughly priced the same.

Just FWIW, I found the link I gave here - http://www.bmw2002faq.com/component/...+manufacturer/

Do you have a link to the henneman site?Comment

-

You're welcome :)

Last real update of the day. It's almost 9:00 and I just finished cutting out the "good" metal to patch my floor. Couple of pics, and that'll be it for today. I'd say it was productive!

Cancer, be gone!

Lay out of the good, the bad, and the ugly (missing! :D)

My ugly mug. Remember kids, safety first! Ah, the end of a good day. :up:

Ah, the end of a good day. :up:

Comment

-

finally some progress. Keep it up and you might be ready for 2002 +10www.classicdaily.net

1970 m42 swapped 2002

1985 LS1/T56 Swapped e28 (557e)

www.blunttech.com - For all your parts needs

Follow me on Instagram for constant build updates @classicdaily

https://www.facebook.com/ClassicDailyLLCComment

-

You inspired me to pull the motor out of my 1600.

I have been staring at it for about 4 months....

It was your empty engine bay shot that did it"We praise or find fault, depending on which of the two provides more opportunity for our powers of judgement to shine."Comment

-

Well FWIW, so far I haven't gotten a chance to get working on the car. I've had to help out getting the race car trailer back in the backyard. Everything was going good until about 10 minutes ago when the stupid @%^*in motorized dolly thing we have for it didn't feel like pushing all the weight up a ramp to the side walk. Playing the waiting game for two smallish car batteries to charge from almost dead, trying again, and finally starting work on the deuce.

One thing regarding the 02 though, is I've pretty much decided it would be best to box in the inside plates. I think I might have to do that with the inside rear ones as well to an extent. I'm not sure 100% where the rear bars will land on the tunnel yet, but it looks like it'll be on a slight angle too, but shying away from the back side.Comment

-

haha! Because I don't have the dough to farm out the work Vlad. I'm not as much of a baller as you are ;) I kind of take pride in doing stuff myself, anyway...but believe me, if I had the money, the bodywork would be one of the last things I'd want to do myself. It's kind of important to get right. I could only imagine the bill to fix the bodywork if I took it to a shop though. Probably the most expensive thing that a shop will get to do to this car, unless I give up and let someone put quarter panels on it, will be the paint (including stripping it to metal). I'd even do that but I don't have a good 60-80 gallon compressor, water trap, or good paint gun! I could buy all that shit for less than the job would cost and have a bunch of tools too, but who knows how good the paint would turn out...I don't think the poor sob story about how long I've had the car, and what it will be like done, would make any of it any cheaper either even at CM :P lol

As far as welding goes today, I think the welding god is frowning on me. I got a late start and it is some seriously tedious work cutting little strips of 8th inch thick metal (not exactly fast with a dremel cut off wheel either, but precise) to box in the inside plates. I have the two pieces for the passenger side front tunnel plate done, but it took me a long time to get even close to right. Im taking a short break, then I'll head out and work on getting the the driver side boxing plates done. That'll probably put me at 6:00 here by then.

If I get motivated I'll probably remove the dried up undercoating off the good piece of metal I'll be patching into the floor too. Maybe even mock it up, mark it and trim it down to size. It's just BARELY larger than the hole in a couple spots. Pretty sure though it's not too small anywhere, I just didn't want to have to remove a lot of material though.Comment

-

By the way, the goal is to get this thing ready for the E30 Picnic, next year. Quite a goal to set without any real income right now, but I should be working on this thing EVERY DAY, doing something.

Kind of set myself up for that one, I've posted it on a public forum :)Comment

-

Alright another end of day update here.

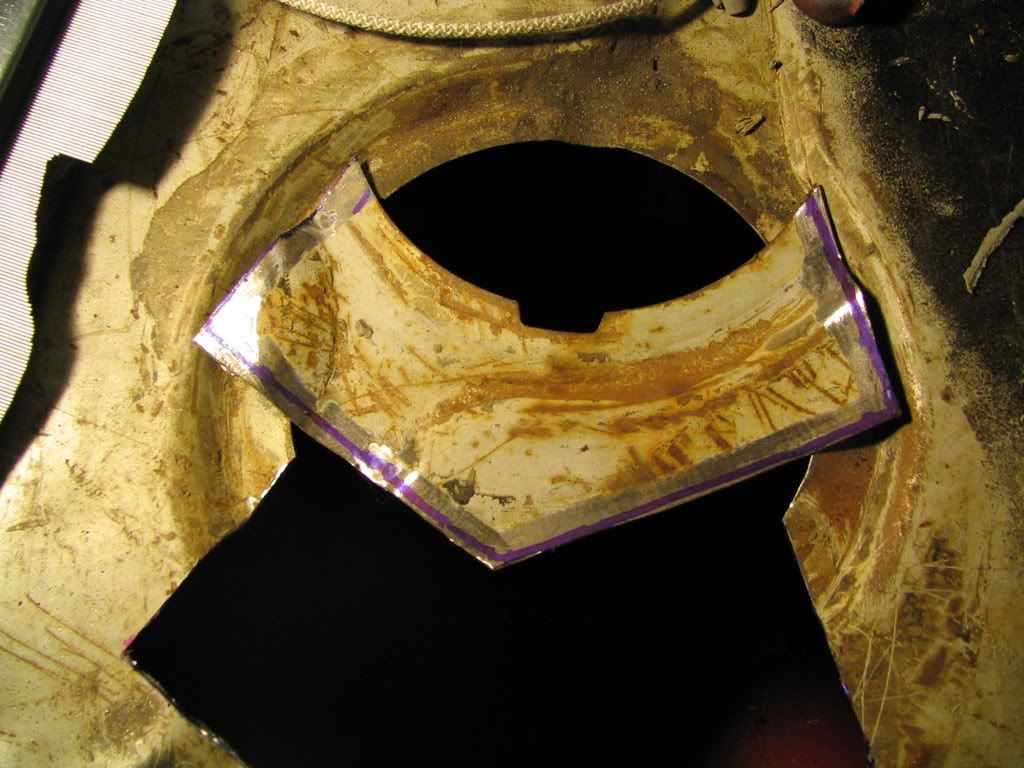

Here's what took the bulk of my time. I'm afraid I'm going to have to do something similar to this for the rear tunnel-side plates as well. That's only the 2nd 1.5" cutting disc I've had to use between cutting out those little strips, and the floor sections. Not bad.

Undercoat begone-

The idea I had here is to put it in the best location possible, then trace the outside edge with a sharpie and cut/grind off the excess.

Something like this.

I probably could have left it like this, but I wanted a little bit of gap between the pieces. It can hold itself in at this point. I ground off a little bit more mostly on the right hand side in this picture.

Poifekt!

I should be busy tomorrow welding in the triangle pieces to box in the plates, probably welding in that floor piece, and at least starting to weld in the rear plates. If I need to box in the rear inside ones like the front I can pretty much gurantee that I won't get it 100% done tomorrow, but probably by Friday.Comment

-

man can't wait to see her done!!! there is not much more i love in the world then a nice 2002. do you mind if i ask where you work? it always interests me to see where people who do this kind of work at home work. i hope i can do this my self some day.sigpic

"The bitterness of poor quality remains long after the sweetness of low price is forgotten."

Comment

-

Well, I'm supposed to be working on gokarts at the kart track at Infineon....but its kind of the off season, being all rainy and everything, and I havent gone into work in like 2 months (edit- not by my choice, just no work). Touchy subject, and I HATE retail (I worked at OSH for 6 months last year), so I'm trying to suck it up till I get work again OR give up on that and try to find work elsewhere but I honestly haven't really looked. I'm going to have to do something pretty soon though.

So basically, I don't. Right now.Comment

-

Hmm. Looking at the pics above #4 in Post #132 it looks like I may be making two patch areas for the water-trap drain holes. I know there's rust there, but it looks like it's poking through in that pic. BRB!!

<30 seconds....>

Alright. Didn't think so. It's definitely pitted there though, and I knew that. As long as I can neutralize it with some of my Picklex20, I'll be fine. I have some POR-15 paste too that can be used to build up weakened metal so I'll use a little there. When I put in the drain plugs they'll get a good smearing of Wurth seam sealer to keep water out from between the two pieces of metal.Comment

Comment