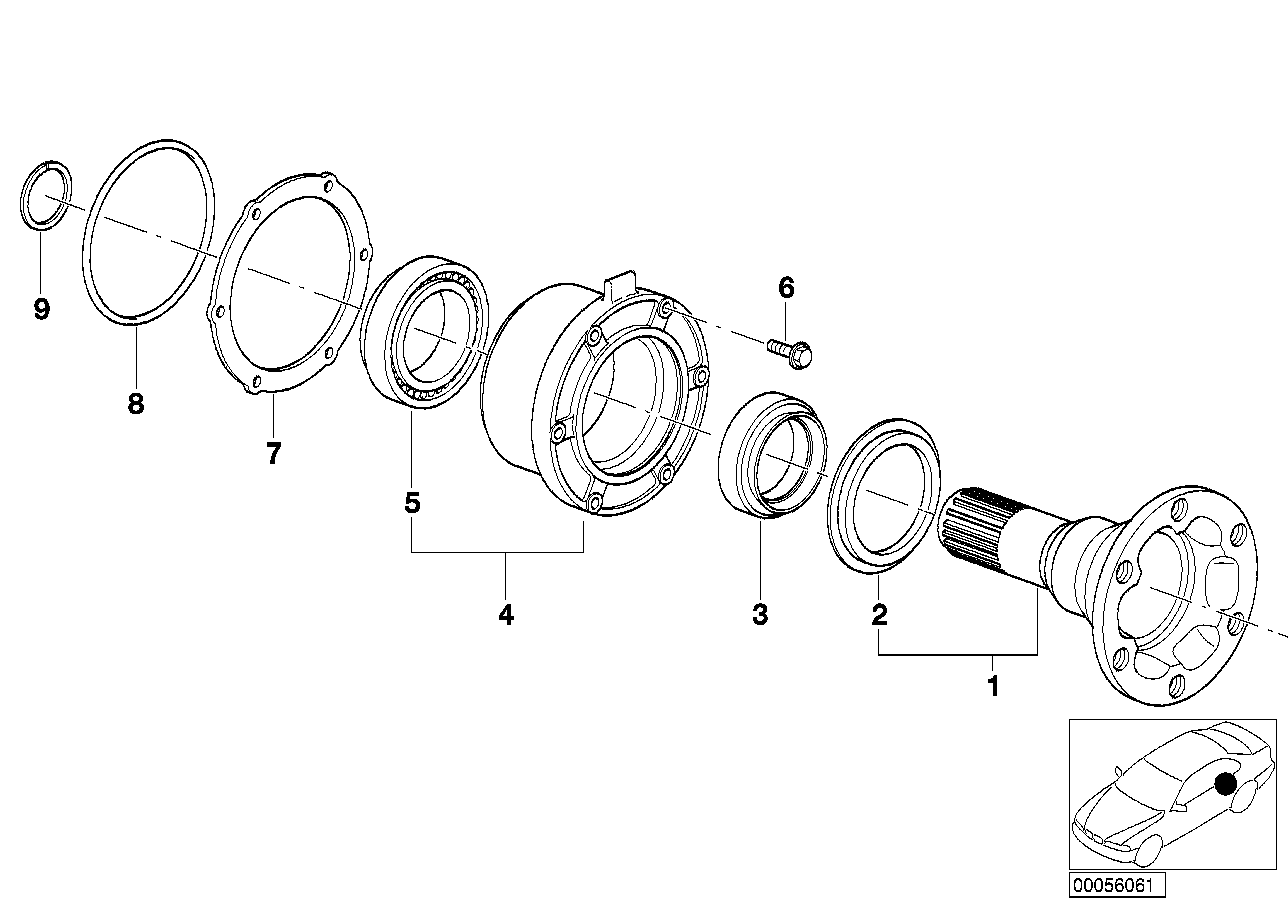

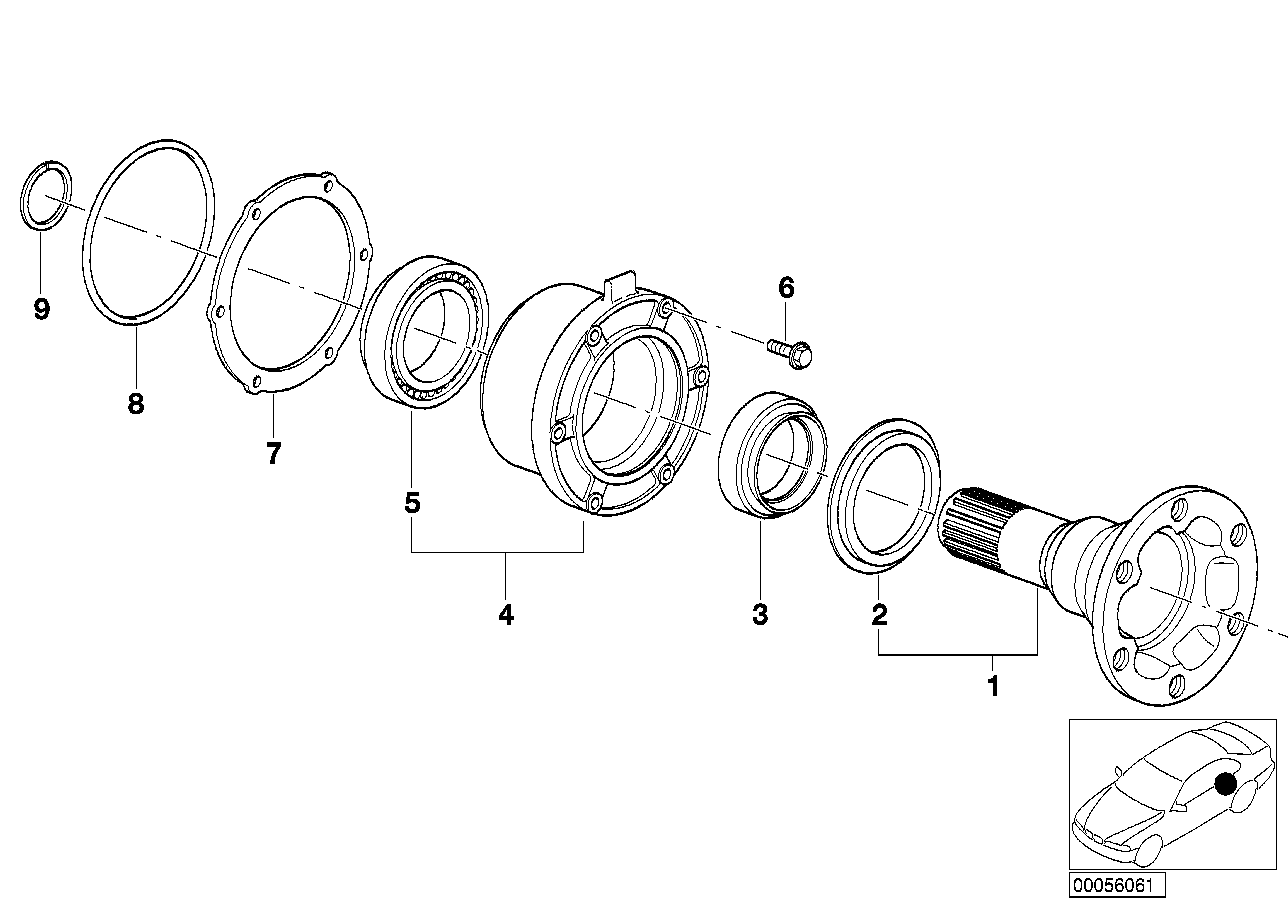

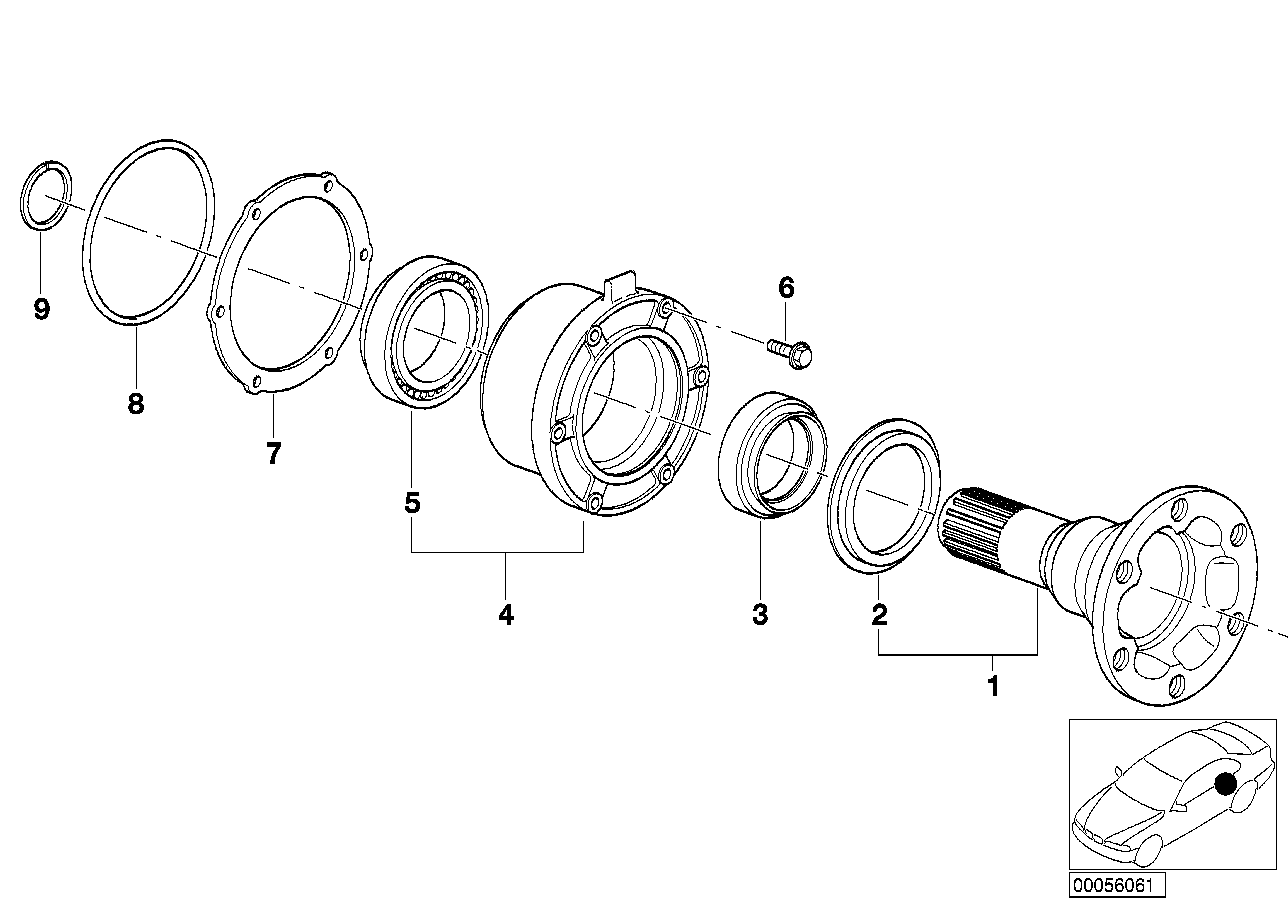

Do you know the part number for the dust shield for the flanges?

Is it

Is it

| 02 | Dustcover plate | 60X84X5 | 2 | 33131208006 |

| 02 | Dustcover plate | 60X84X5 | 2 | 33131208006 |

As you can see , the alternator didn’t receive any attention . I was not confident to take it apart .!

As you can see , the alternator didn’t receive any attention . I was not confident to take it apart .!

I will need to modified the throttle body : -Built a block off plate for the coolant holes and the pcv tube -JB weld or real weld the elbow that are always loose on our TB -add another vaccum port for the vaccum distributor box I want to make. As every time , all this will be refresh ! I also start to pull the engine .

I will need to modified the throttle body : -Built a block off plate for the coolant holes and the pcv tube -JB weld or real weld the elbow that are always loose on our TB -add another vaccum port for the vaccum distributor box I want to make. As every time , all this will be refresh ! I also start to pull the engine .  Car on jack stand Pretty much is disconnected (electrical and mechanical) Maybe an hour of work Again and I will (try) to pull the engine off. First time for me , finger crossed haha !

Car on jack stand Pretty much is disconnected (electrical and mechanical) Maybe an hour of work Again and I will (try) to pull the engine off. First time for me , finger crossed haha !

Everything has been pretty good. It is straightforward . Unconect things that is attached to the engine , then pull. Seriously , you don’t need spécial tool , except the engine hoist and engine leveler. Took me 5h hours from the time I stop the car in it’s place to the engine on the ground .

Everything has been pretty good. It is straightforward . Unconect things that is attached to the engine , then pull. Seriously , you don’t need spécial tool , except the engine hoist and engine leveler. Took me 5h hours from the time I stop the car in it’s place to the engine on the ground .  I am happy , this is a big step for a man who never done this haha! Look what 30 years can do to an engine

I am happy , this is a big step for a man who never done this haha! Look what 30 years can do to an engine

Now I have plenty of work ahead !

Now I have plenty of work ahead !

Next, the dirty tranny

Next, the dirty tranny

-deep clean -fresh seal all around -fresh oil -fresh misc part

-deep clean -fresh seal all around -fresh oil -fresh misc part

I don’t wait any second and install them on the engine , and install to , temporary , the manifold and the turbo

I don’t wait any second and install them on the engine , and install to , temporary , the manifold and the turbo  So good looking but .. I got an issue with the turbo and the spark plug wire . They touch the turbo housing and blanket + they will be very close to the downpipe ..

So good looking but .. I got an issue with the turbo and the spark plug wire . They touch the turbo housing and blanket + they will be very close to the downpipe ..

At first I taught I can modify the manifold . To see how much I can play with it , I install the engine on the engine bay

At first I taught I can modify the manifold . To see how much I can play with it , I install the engine on the engine bay  Then I realize i have 0 space to modify the manifold . It is close to the frame rail and will be at 1/2“ from the hood ..

Then I realize i have 0 space to modify the manifold . It is close to the frame rail and will be at 1/2“ from the hood ..

So , at the moment I’m working on a solution to push the spark plug wire toward the intake manifold . To be continued .. About the throttle body . I have delete the coolant pass in the throttle . For those who ever think about how the coolant pass in the TB . In fact , it doesn’t pass inside the TB , the coolant only touch it via little Chanel .

So , at the moment I’m working on a solution to push the spark plug wire toward the intake manifold . To be continued .. About the throttle body . I have delete the coolant pass in the throttle . For those who ever think about how the coolant pass in the TB . In fact , it doesn’t pass inside the TB , the coolant only touch it via little Chanel .  I also remove the pcv return and weld the hole . Since I will run an catch can , I no longer need this port. I also make an block off Plate for the coolant pass .

I also remove the pcv return and weld the hole . Since I will run an catch can , I no longer need this port. I also make an block off Plate for the coolant pass .

I also add a second port for extra vacuum source . Then the IAC elbow and the 2 vacuum elbow were loose and it is impossible to weld it to throttle since it’s not compatible . So I « cold weld » it with permatex stuff.

I also add a second port for extra vacuum source . Then the IAC elbow and the 2 vacuum elbow were loose and it is impossible to weld it to throttle since it’s not compatible . So I « cold weld » it with permatex stuff.  Way way better than JB weld . To make it strong AF , I « cold weld » it in 2 step , first step was before push them into place , and second step was at the outside to make an « sandwich » with the glue .

Way way better than JB weld . To make it strong AF , I « cold weld » it in 2 step , first step was before push them into place , and second step was at the outside to make an « sandwich » with the glue .

It is so strong . The only concern I have will be the longevity since the aluminium could expand/retract with all the heat .. time will tell ..! Little coat of paint to make look fresh

It is so strong . The only concern I have will be the longevity since the aluminium could expand/retract with all the heat .. time will tell ..! Little coat of paint to make look fresh

Next will be the tranny cleaning ..!

Next will be the tranny cleaning ..!

I wanted a better result but , I have give enough time to this transmission , it’s way better than before anyway ! All the seal were do 2 years ago so , except an oil change , no more work on it ! I also work on the engine bay . -remove the abs pump and line (will redo the brake line ) -remove all unnecessary braket -start to clean before the body work

I wanted a better result but , I have give enough time to this transmission , it’s way better than before anyway ! All the seal were do 2 years ago so , except an oil change , no more work on it ! I also work on the engine bay . -remove the abs pump and line (will redo the brake line ) -remove all unnecessary braket -start to clean before the body work

Comment