June 19th, 2021

Phase two of engine cleaning occurred, and it was easier than expected. The block cleaned up very nicely.

I found an LS1 engine reassembly guide, and then another, and then another, online. So I read through them all to begin the reassembly process for my LM7.

I also purchased a 3M Bristle Disc to clean up the block side of the head gaskets. It's similar to a paint stripping disc, just not as aggressive.

Packed all of the openings with rags and shop towels and rotated the engine on the stand so that the surface I was working on was flat.

Gingerly used the disc to remove all gunk, leaving the surface nice and shiny.

Turned the engine upside down before removing all of the rags and towels.

Used my air compressor to blow any remaining residue out of cylinders and coolant channels.

Repeat for the other side.

I was nervous about this part, so I was excited when it was done and I hadn't ruined anything.

I chased the other mating surfaces on the block with the disc as well while I had it out.

After that was done I continued with the engine assembly, reinstalling the oil pump, new pickup tube for the F-body pan, and front timing cover.

The timing cover cannot be torqued down until it is appropriately set over the crank and harmonic balancer (HB), as that is what it seals to.

So this forced me to determine what HB I wanted to use. There are 3 different depths depending on what vehicle the LS was installed in. The C5 corvette is the most shallow, so that's the HB that I went with. Ordered an OEM version.

I also had to make sure this HB would work with the alternator relocation bracket I am going to use, as I will be running an electric water pump in place of the much larger and more cumbersome C5 corvette mechanical water pump.

Everything checked out, so I ordered another handful of parts for delivery.

Head bolts and a variety of other parts all arrived and are waiting their turn for installation.

I dropped off my F-Body oil pan to a local welding shop last week. They are welding on the -12AN bung to the passenger side of the oil pan for the turbo oil return line. They only do aluminum once a week so it will be done one day this upcoming week.

I won't be able to install it until I torque down the front timing cover and verify it's spacing to the bottom of the block, as the pan seals to the bottom of that cover.

No pictures, but I should have some soon enough.

The 1,000 hp twin disc clutch has arrived. A thing of beauty it is.

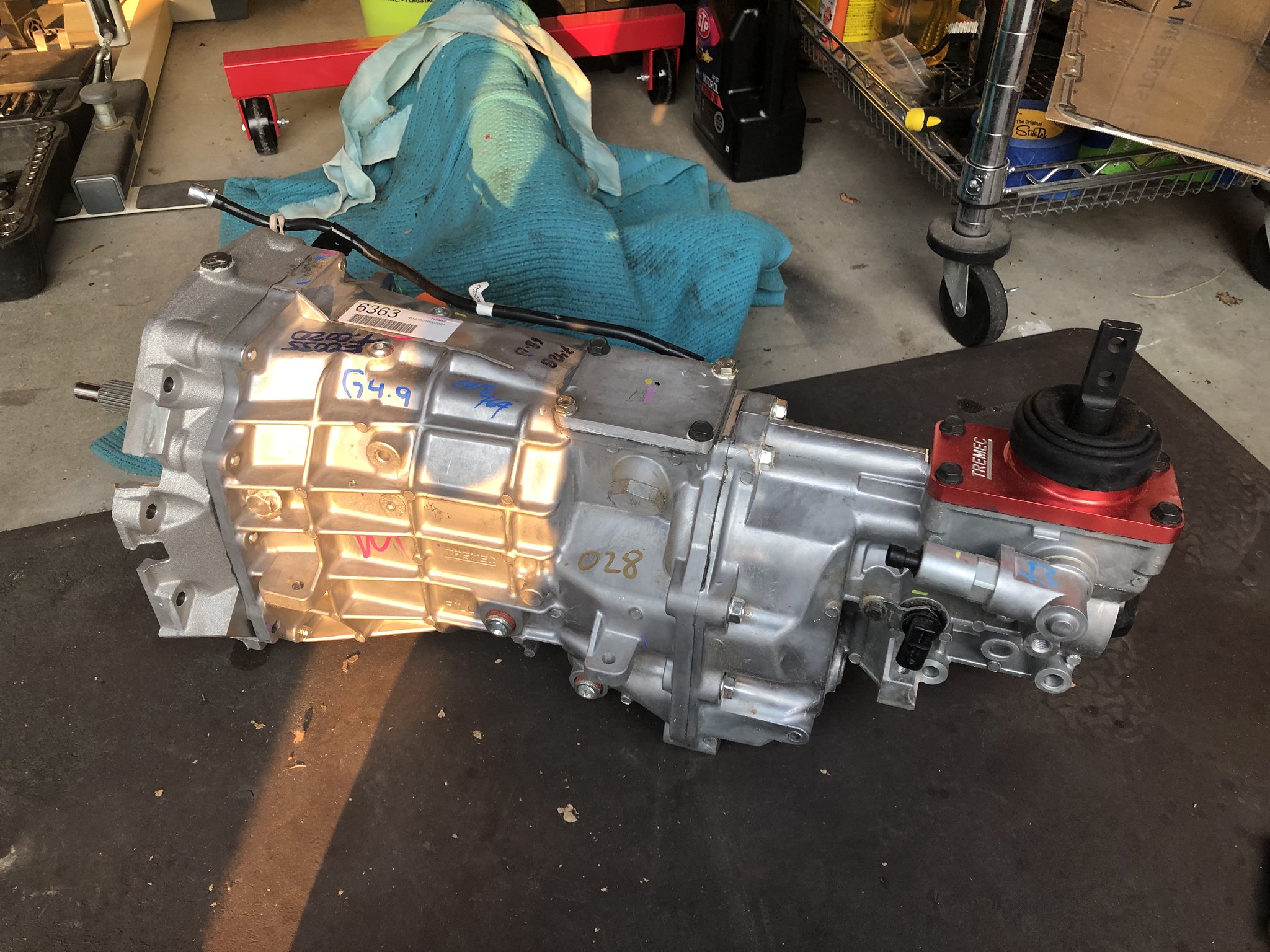

The incredibly expensive Tremec T56 Magnum-F 6 speed manual transmission, with hybrid gear ratios, built to withstand over 700 ft*lbs of torque, arrives on Monday. I am VERY excited about this part.

Approximate Hours Invested in Project Since Purchase: 442

Phase two of engine cleaning occurred, and it was easier than expected. The block cleaned up very nicely.

I found an LS1 engine reassembly guide, and then another, and then another, online. So I read through them all to begin the reassembly process for my LM7.

I also purchased a 3M Bristle Disc to clean up the block side of the head gaskets. It's similar to a paint stripping disc, just not as aggressive.

Packed all of the openings with rags and shop towels and rotated the engine on the stand so that the surface I was working on was flat.

Gingerly used the disc to remove all gunk, leaving the surface nice and shiny.

Turned the engine upside down before removing all of the rags and towels.

Used my air compressor to blow any remaining residue out of cylinders and coolant channels.

Repeat for the other side.

I was nervous about this part, so I was excited when it was done and I hadn't ruined anything.

I chased the other mating surfaces on the block with the disc as well while I had it out.

After that was done I continued with the engine assembly, reinstalling the oil pump, new pickup tube for the F-body pan, and front timing cover.

The timing cover cannot be torqued down until it is appropriately set over the crank and harmonic balancer (HB), as that is what it seals to.

So this forced me to determine what HB I wanted to use. There are 3 different depths depending on what vehicle the LS was installed in. The C5 corvette is the most shallow, so that's the HB that I went with. Ordered an OEM version.

I also had to make sure this HB would work with the alternator relocation bracket I am going to use, as I will be running an electric water pump in place of the much larger and more cumbersome C5 corvette mechanical water pump.

Everything checked out, so I ordered another handful of parts for delivery.

Head bolts and a variety of other parts all arrived and are waiting their turn for installation.

I dropped off my F-Body oil pan to a local welding shop last week. They are welding on the -12AN bung to the passenger side of the oil pan for the turbo oil return line. They only do aluminum once a week so it will be done one day this upcoming week.

I won't be able to install it until I torque down the front timing cover and verify it's spacing to the bottom of the block, as the pan seals to the bottom of that cover.

No pictures, but I should have some soon enough.

The 1,000 hp twin disc clutch has arrived. A thing of beauty it is.

The incredibly expensive Tremec T56 Magnum-F 6 speed manual transmission, with hybrid gear ratios, built to withstand over 700 ft*lbs of torque, arrives on Monday. I am VERY excited about this part.

Approximate Hours Invested in Project Since Purchase: 442

Comment