What prompted the use of the e36 intake manifold?

e30guydownunder: Project M42, probs definitely got more power than your S50

Collapse

X

-

-

Mostly it was what I had spare to use in the front cut. of course that has since changed, but a few other points.

The E30 M42 manifold has been proven to be an inlet restriction, reverse flow (180 degree flow direction changes) are not good! This is a bit nicer in that respect.

It was also easier to adapt this to take the M30 throttle body, all I did was hack the front / old flange off and make up a new one :)

I won't be running the inlet flappy valve as the engine is always above 3500rpm anyhow so the valve would not affect / improve the driveability of this car.Comment

-

I've also been pondering using an electric waterpump like the one you are on my turbo m10 build.

From what I was told by a friend (running it on a Ford Small block), is that he just removed the pump and t-stat. Hooked the new electric water pump up to the lower radiator hose. He's never had a days trouble.

Thing that makes me think though is that will create constant water flow through the radiator, so wouldn't it mean it would take longer to get the engine up to temp?

Comment

-

Thanks for the input.

Straight from DaviesCraig Website. http://www.daviescraig.com.au/Electr...P-content.aspx

I am using the controller and pump kit. The controller vaires the on/off time of the pump to change the flow characteristics in order for the water temp to come up quickly and then be maintained. My controller is also one of the later model ones which controls the fan as well.Question No. 11

Is the idea that coolant can pass too quickly through a radiator true?

The "pump too fast lose less heat” notion is very popular and many experienced mechanics are very attached to it but – it is a fallacy. Davies Craig has been carrying out research and development for over a decade on a number of projects and has never been able to pump genuine liquid coolant faster and lose less heat. In all car engines, when the mechanical pump reaches cavitation speed, coolant turns into a gaseous state which is compressible,(liquid is not) and the real flow rate of liquid coolant drops even though the mechanical pump has a higher rpm, and so heat loss drops. The engine temp then rises. And it only seems like the flow rate is too fast, and the coolant is spending too little time in the radiator to lose its heat etc. etc..

Question No. 12

My vehicle is fitted with a thermostat bypass what should I do when I wish to replace the existing mechanical water pump with an EWP®?

Where there is a thermostat bypass in some engines including those produced by BMW & ROVER, there may be a bypass from the thermostat housing back to the water pump chamber so when the thermostat is fully closed, coolant passes directly from the engine block to the thermostat housing and then straight back to the block without passing through the radiator. When fitting your EWP® to an engine which uses a bypass valve style thermostat, after you have removed the thermostat, you will need to block off the bypass passage (with a core plug or similar), to prevent flow from your EWP passing directly back to the radiator without passing through the block.Comment

-

Good to know on the intake. Forgot about that pesky 180 degree turn. I've heard that using the e36 manifold interferes with the stock brake booster, fwiw.Comment

-

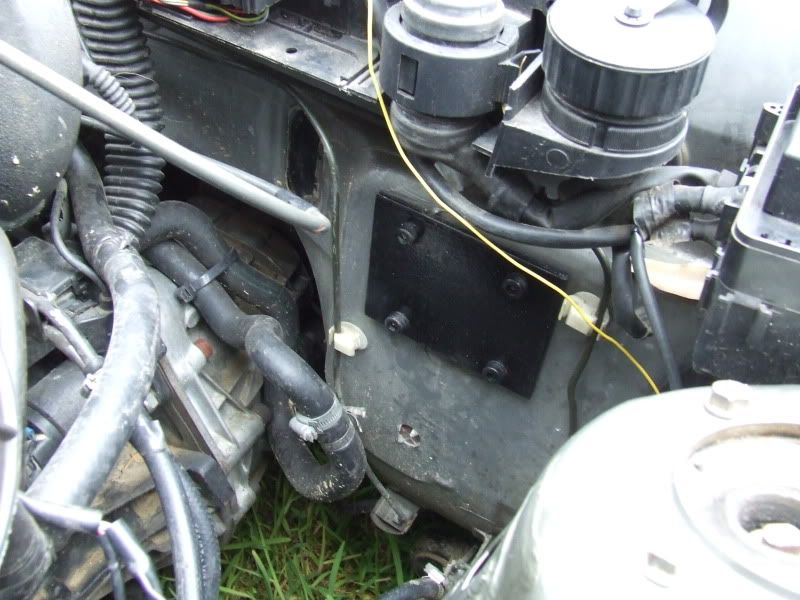

It's just as wel;l my booster looks like this then :)

Got my Twin master cylinder setup in and working finally. Just need to move the fuse box and then I can mount up the fluid reservoir properly.

Comment

-

Preparations have begun for a trackday March 19th. Advan A050's should arrive this week and the continual aquistion of parts for boost continues.

Comment

-

I'm nearly caught up to your rate of progress! The Daily's have been giving me hell, moving from the E30 was a bad idea.

Pretty keen to get it out and try some new tyres though. Should be good fun. Will have my GoPro ready also.Comment

-

This project is not ded, the engine is in the shed upside down, with no head and a hlf constructed aluminium sump.

MLS has been ordered...O-rings seem like a bit much stuffing around and SHOULD in reality work.

should be an interesting update within a month if I plan on attending the next track day ;)Comment

-

Thanks for the pics dave. Looks great!

My Good Friday has been good!

Kept the sump up above the crossmember height, no more cracked pans for me!

All the bits ready to be welded together:

Pretty happy with how it has come along. Good things: Standard dipstick now works, oil pickup in the flange of the sump is as factory and no chance of it stuffing up -> engine failure, aluminium has a better heat rejection than steel, the thing doesn't weight 10kgs!Comment

-

Gotta slow this shit down:

Today work started on the brakes. Wakefield raised a heavy brake pedal as an issue with the new pedal setup. Rather than buying ANOTHER set of master cylinders, obviously the logical thing to do is fit larger calipers. I'm going to need something once turbo'd anyway.

I wasn't happy with how the GTR brake setup was going to work out under a 15". Really need 16" wheels to run a 296mm disc successfully, can just imagine rocks getting in there and tearing the wheels to shreds.

So we have gone with some 280mm discs up front, 270mm down back and I'm using sliding WRX Calipers....I know, not a racing caliper, BUDGET. I've been struggling to give these things away and they seem to work decent on the WRX anyway. The lil E30 is some 400kg's lighter also.

I need some spacers behind the front rotors to get the backspacing where I want it....The E30 front rotors worked out nicely :D

These were machined to the right OD to locate the rotor hubcentrically:

The rear rotors are the right backspacing but will need the PCD redrilled. So I machined down an old front hub (centre bore was too big) to suit the rear rotors and drilled the locating hole thru from the standard rear rotor. Now I have a drilling template for the new rear rotors.

Comment

-

Alright so Today I got down to business and shit is going at quite a pace :)

For a while now the front and rear rotors were in a state they fit on the hubs:

Rears:

Front Spacer:

Front Rotor:

The calipers were just sitting on for those pictures. But today I fixed that!

The Rear's use a simple 10mm flatbar adapter:

The Rear's all bolted up:

The front's were a lil more complicated. Where the caliper is sitting I didn't have enough space for an adapter between the upright and where the caliper was. So it had to go out and around:

From the front:

A view of the bit's made to date:

I didn't know the rear rotor hats weren't going to be as thick as the original rotors, so the 3mm spacer was made. This also got me out so the 10mm adapter would work nicely.

All thats left is to make some hub centre extendo's for the fronts (like the Turner Motorsport items). And one more rear brake rotor spacer. Then I just need to order the new front hubs and rear wheel bearings. My press in studs are here ready to go.

Now I can focus on rebuilding the engine and getting this thing ready for an event in July.Comment

-

Good work slutbags, hope you made 2 of everything ;)Your signature picture has been removed since it contained the Photobucket "upgrade your account" image.

Originally posted by der affefirst try a finger or 2, you need to have them suck on it first and get it nice and wet to help it slip in.

if she goes for that, astroglide up your pole, have her lay on her stomach and slip it in slowly and bury it to your balls and leave it there until she relaxes. once she is used to it slam that ass like a screen door.Comment

Comment