Little update:

Its spring break for me now so I'll try to get everything that

I can get done with no money done this week. My leg is

healed now so I'm back to work and should have a good regular

cash flow again so that will help.

Also Its the RedBull Crashed Ice this week-end in Québec city...

I will miss most of it though.

So I dissembled my calipers and decided that I'm getting them powder

coated black, SS pistons for the front and solid brass guides on all of

them.

Then I removed the booster in preparation for the booster delete kit that

Lee (Massive) designed.

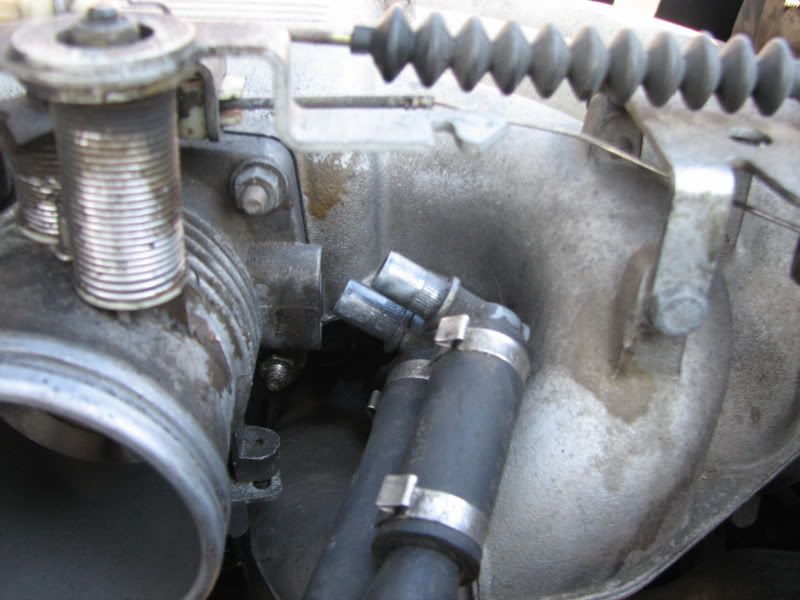

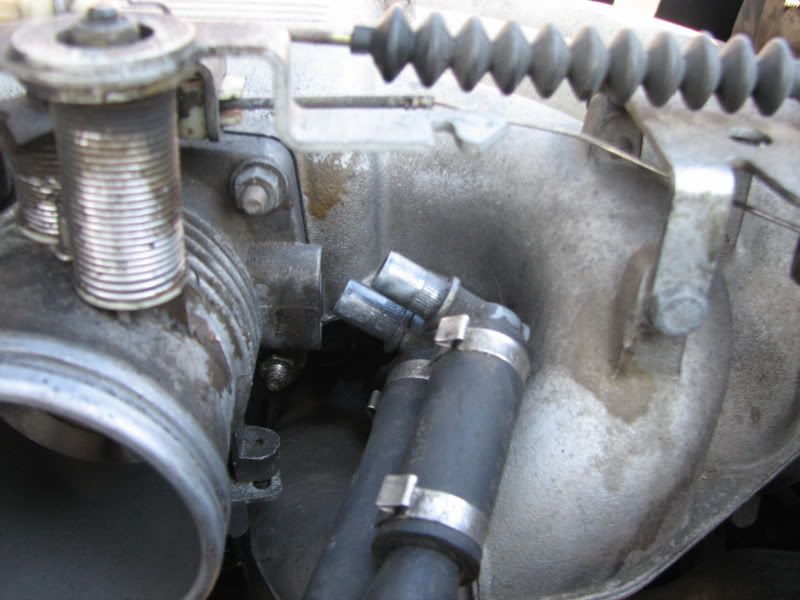

When I removed the hoses between the booster and the TB, I found one

of my vacuum leaks source, I just pulled them out.

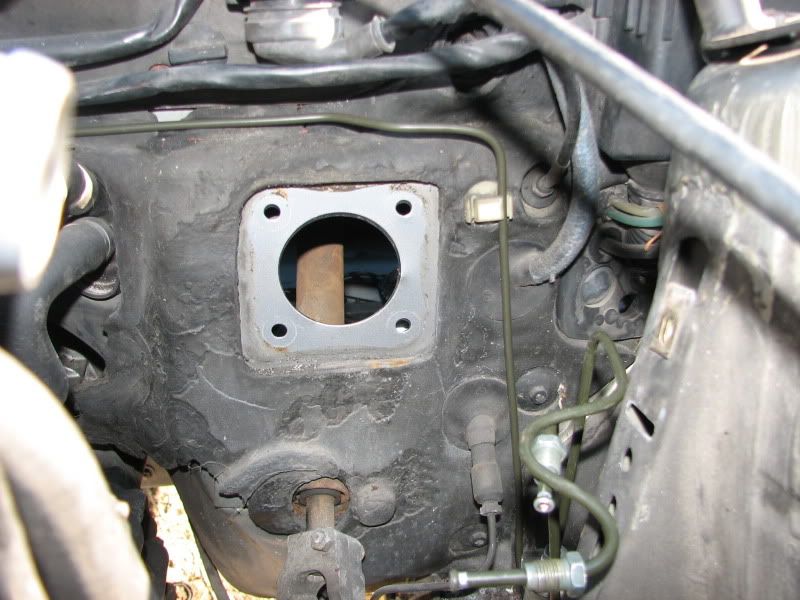

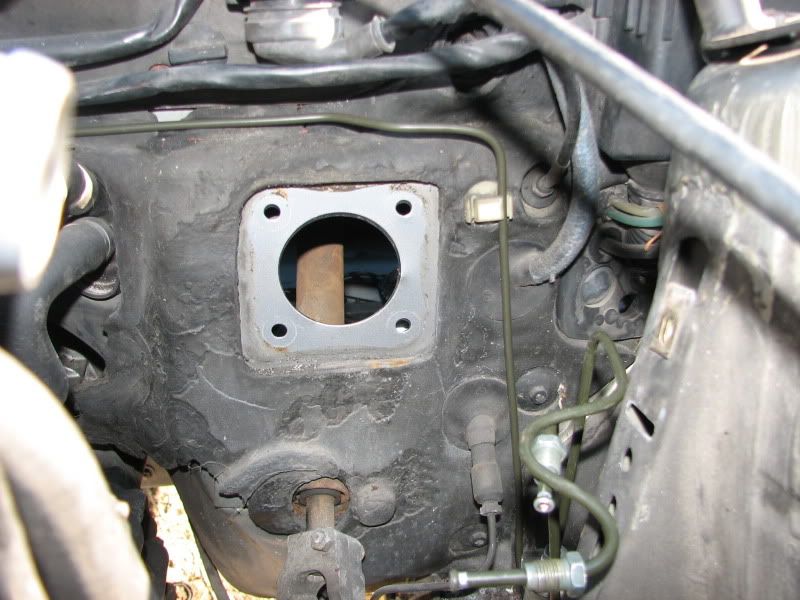

This is how my setup looked like after my ABS delete I did early last fall.

Those of us who have already removed/swapped a booster know that

getting the 4 nuts out can be a pain. But today I went really well.

Since I'm installing the Massive booster delete bracket, the brake pedal

needed to come out sooner or later so I started by this. The brake pedal

and the clutch pedal are on the same axle/bolt but its possible to slide the

bolt only half way out and take the brake pedal out without taking the

clutch one out.

Caution: If you are not careful you can damage the wiring with the head

of the bolt when you slide it out. I also broke my brake light

switch wiggling out the pedal...

Then when the pedal is out and the knee panel as well reaching the four

nuts is very easy with a deep 13mm socket+extensions+swivel+ratchet.

Getting the booster out of its spot ended up being some kind of puzzle but

I got it out eventually.

I also removed the insulation that was behind the booster

and the fuse box. I had the impression that I was removing play dough.

I did find a small rust hole behind the fuse box that was hiding behind

the insulation. One more thing to fix....

Trying to figure out the cleanest way to reroute the brake lines. I will be

neat when done

Charley

Its spring break for me now so I'll try to get everything that

I can get done with no money done this week. My leg is

healed now so I'm back to work and should have a good regular

cash flow again so that will help.

Also Its the RedBull Crashed Ice this week-end in Québec city...

I will miss most of it though.

So I dissembled my calipers and decided that I'm getting them powder

coated black, SS pistons for the front and solid brass guides on all of

them.

Then I removed the booster in preparation for the booster delete kit that

Lee (Massive) designed.

When I removed the hoses between the booster and the TB, I found one

of my vacuum leaks source, I just pulled them out.

This is how my setup looked like after my ABS delete I did early last fall.

Those of us who have already removed/swapped a booster know that

getting the 4 nuts out can be a pain. But today I went really well.

Since I'm installing the Massive booster delete bracket, the brake pedal

needed to come out sooner or later so I started by this. The brake pedal

and the clutch pedal are on the same axle/bolt but its possible to slide the

bolt only half way out and take the brake pedal out without taking the

clutch one out.

Caution: If you are not careful you can damage the wiring with the head

of the bolt when you slide it out. I also broke my brake light

switch wiggling out the pedal...

Then when the pedal is out and the knee panel as well reaching the four

nuts is very easy with a deep 13mm socket+extensions+swivel+ratchet.

Getting the booster out of its spot ended up being some kind of puzzle but

I got it out eventually.

I also removed the insulation that was behind the booster

and the fuse box. I had the impression that I was removing play dough.

I did find a small rust hole behind the fuse box that was hiding behind

the insulation. One more thing to fix....

Trying to figure out the cleanest way to reroute the brake lines. I will be

neat when done

Charley

It was a quick fix...

It was a quick fix...

.

.

Comment