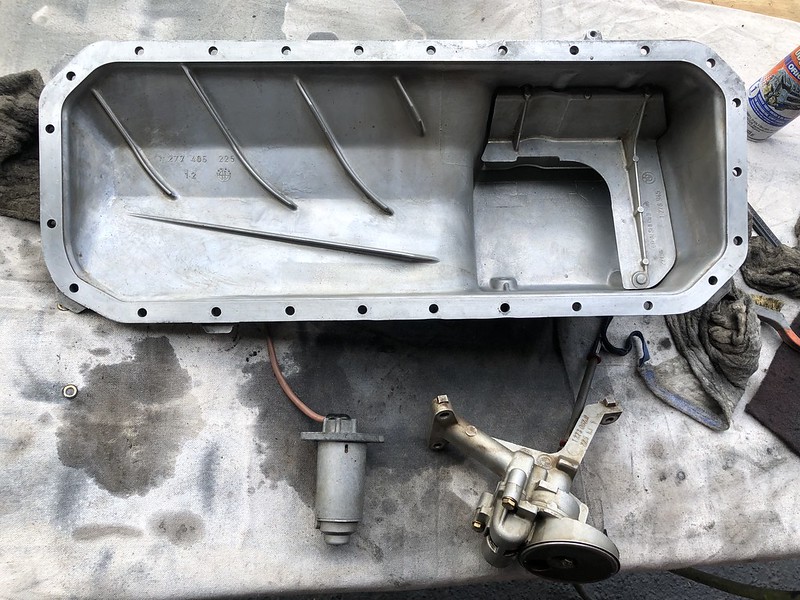

In order to get it off, I ended up loosening the engine mount bolts and jacking the engine up as much as I could, loosened but did not fully remove the steering rack, and removed the oil pump. Not as bad as I was anticipating. It was a tight fit but easily slid the oil pain out:

Cleaned up the pan, pump, oil level sending unit, and the underside of the block. The old gasket was basically plastic and flaked off:

Used a light layer of Curil K2 to seal the new gasket to the pan so that it wouldn't move around on reassembly:

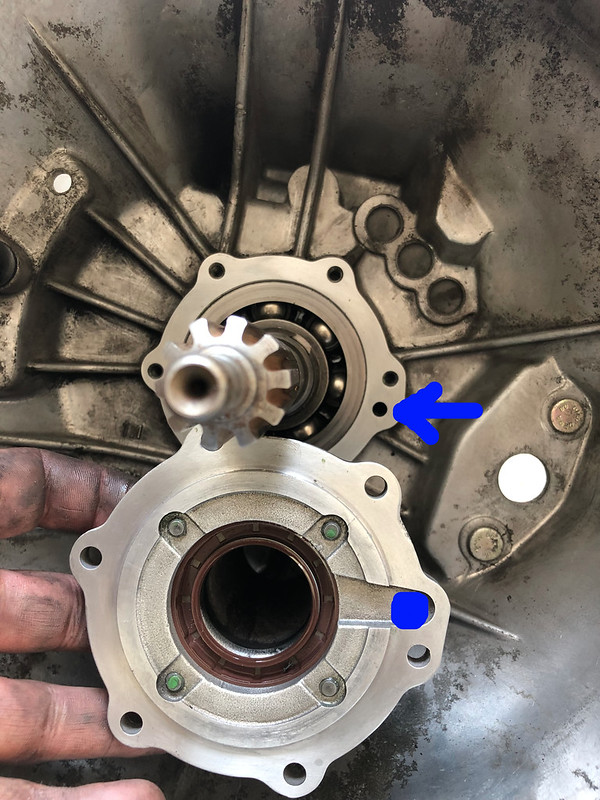

Also use a little dab where the rear main seal carrier as well as the crankshaft seal carrier mates to the block:

Slid the pan under the block and got the oil pump back in place. Not many pictures as it was quite the balancing act. Toughest part is getting the oil pump drive shaft back in place, it's just hard to see where it inserts into the block while balancing the pump with only a couple inches between the block and the pan. Got the pan back on and snugged up the new bolts in a star pattern, inside-out.

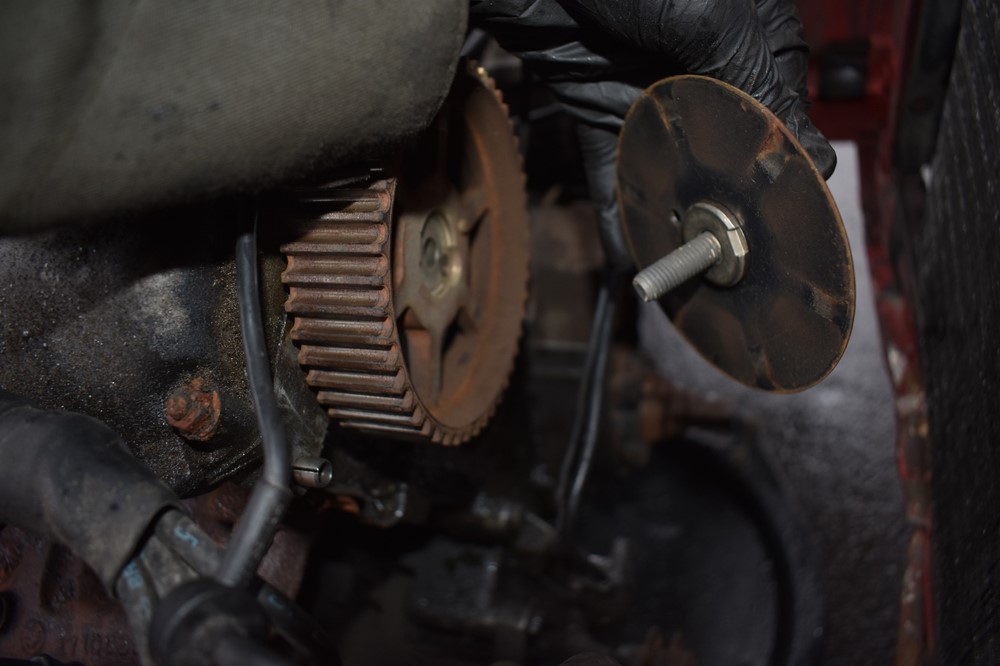

Making good progress, I decided to get the trans back in. Obligatory resurfaced flywheel shot:

New pilot bearing:

Got the flywheel 3/4's of the way on before I remembered to put the starter alignment plate back on (D'oh), and got the clutch and pressure plate on. After a bit of wrestling around under the car on the jack, voilà:

We offically have a manual e30! I've made some more good progress, but I think this is more than enough pics for one post, and #200 for me no less! I hope to have the car running within the week, waiting on one or two odds and ends to ship.

Leave a comment: