I’d get it warmed up and block the icv to see if there’s any change. Presumably it’ll run ok without it. That will isolate the issue to the icv or something else

M42 Head Gasket Blown, Project Thread

Collapse

X

-

89 E30 325is Lachs Silber - currently M20B31, M20B33 in the works, stroked to the hilt...

new build thread http://www.r3vlimited.com/board/showthread.php?t=317505

-

I have experimented a little with the ICV. In the cases where the idle was too high (stable or oscillating), unplugging the ICV would make the idle return to normal. As mentioned, the AFM output was indicating that the ECU was purposely opening it that much for some reason since it looked to be the case that the extra incoming air was all metered.

I have not tried unplugging the ICV when the engine wants to stall, but it makes sense to try. If the ECU sometimes decides to open it too far, maybe the stalls are because it is not opening it enough?

I can try pinching off the hose to the ICV when it is idling too high, just to rule out any other source of incoming air. At this point, I am 99% sure that the ICV itself is not the culprit. It operates smoothly on the bench with a variable power supply and does not stick at all. I have tried 2 different ICVs to no avail. I also tried swapping in a spare ECU and it also did not improve things, so the mid-current driver stage that drives the ICV is also not the issue.

It seems that there is some erroneous signal somewhere that is confusing the Motronic and making it operate the ICV incorrectly. Evidence I have so far indicates that the ICV's operation is a symptom rather than the illness itself.

The engine runs too smoothly at all throttle positions from 1000-4000RPM for me to suspect a physical issue with the intake or fuel supply system.Comment

-

A modified engine will start, run, and idle with a stock ECU. Just don't get into MBT, more than likely, the stock table will be too advanced.

That being said, return to stock, or go stand alone for easy diag.

Just an FYI, the Dyno plot for the squid stock upgrade is my Dyno sheet, sent it to him when testing the second m20 ITB car we did back in 14(?) when doing the base runs....

I prefer NOT to sell chips on the interwebs, though, live/remote and/or local only. Never was a believer in "stage 1,234,567”. Every engine has specific demands IMO.

Comment

-

There were probably a few seconds here and there of MBT when driving it around since I was aiming to do at least a little break-in. It was all 2000-4000RPM with one or two little bursts to almost 5000 which did not feel great, but I did not hear any indication of detonation. But yeah, no more of that until it idles properly.

I had some pretty wonky tunes provided remotely very early on and the car ran fairly well with those compared to what it is doing now. I just hope that all of my re-wrenching and probing will turn up something conclusive. Tunes that Sssquid came up with for engines built to the same spec might not be perfect for my individual engine (which is why I was doing tons of data logging and sending it to him), but it would at least run "well" I think.

Maybe I just need to forget about this for a week and spend time doing other stuff. I think I am burning out a bit lol.Comment

-

i agree, but you need to make sure there arent multiple issues so id verify when the ICV is totally isolated from the engine that there are zero other issues89 E30 325is Lachs Silber - currently M20B31, M20B33 in the works, stroked to the hilt...

new build thread http://www.r3vlimited.com/board/showthread.php?t=317505

Comment

-

If you are logging, then remote is fine. I was tuning an m20 on a Dyno in Denver last Sat using the Dyno plot and logs.

Digger is onto something. At work, we often will disconnect the ICV and plug the hoses for diag. A 3mm vac hose going from the intake boot to manifold will let the car idle, and keep the air metered via AFM. Just don't expect to rev it much until it warms up, the ICV opens quite a bit on tip in, when in closed loop. It will want to stall with throttle input during warm up.Comment

-

Sounds good, I will keep with the stock tune, stock AFM and experiment with removing the ICV from the loop. Once I get the engine warmed up, I will try pinching-off the ICV feed line to make sure that air is not getting in elsewhere. If that checks out, I will replace the ICV with some spare 3.5mm vacuum hose I have left from replacing the FPR vac line.If you are logging, then remote is fine. I was tuning an m20 on a Dyno in Denver last Sat using the Dyno plot and logs.

Digger is onto something. At work, we often will disconnect the ICV and plug the hoses for diag. A 3mm vac hose going from the intake boot to manifold will let the car idle, and keep the air metered via AFM. Just don't expect to rev it much until it warms up, the ICV opens quite a bit on tip in, when in closed loop. It will want to stall with throttle input during warm up.

Firebird, do you happen to know if the INPA/EDIABAS software will be of any use for reading various runtime parameters in real time? I have the "Factory Interactive" service manual, and it has a decent amount of troubleshooting guidance for the various signals, if one has the diagnostic software. It looks like the INPA software is fairly easy to find around the web, and K-line interface adapters also seem to be reasonably cheap.

I also found the PN for the 88 pin breakout box for testing all of the signals in/out of the Motronic, but if anyone actually sold them they would not be worth the cost. Someone in Eastern Europe has to have old BMW dealer stuff...if only I could find them!Last edited by bmwman91; 06-23-2020, 08:37 AM.Comment

-

I haven't experimented with logging Motronic since I use an emulator, there's data tracing (kinda like "follow mode" in aftermarket ECU's), so you can see what cell the ECU is using on the various maps, and make corrections.Comment

-

A thing I have done in the past is use an Arduino to tap directly into the UART lines for the microcontroller and communicate directly that way. It is then all simple TTL signaling with a total bypass on the one-wire K-line interface. You probably saw my threads where I totally reverse engineered M1.7 and M1.7.3, so it was fairly easy to determine how to do it. The same deal applied to the L-line, which was only used for a one-time 100-baud handshake to make the ECU enter diagnostic mode. No need for any level shifters or one-wire logic that way. That is how I dumped the 8K ROM on the MCU, allowing me to form the full 40K binary (8K MCU ROM + 32K UV-EPROM) and get IDA to disassemble it properly. The 8K on the MCU is all of the interrupt vectors, which are needed to be able to trace anything since the program counter needs to be directed correctly from the start, and I found a very old HTML site with a list of commands and the protocol for telling the ECU to dump blocks of ROM and RAM.

Anyway, you probably knew all that already. The point is that I could also solder some wires from the various TTL-side lines of the L- and K-lines to unused pins on the Motronic connector, and route those wires out to an Arduino. It is my understanding that all of the axis descriptors for the maps (3B, 4A, etc) are actually RAM addresses for those very parameters. So, many of the runtime variables that I'd want to watch are already pretty well known in terms of location and scaling into physical quantities. The stock K-line interface is slow, but it would be easy enough to use VB.NET to make a basic interface to poll the values and display them.

The other test I am going to do, along with you and digger's recommendations above, is to pop the hose for the ICV from the intake boot and see what happens if I apply ~5PSI. I expect a little leakage from the TB, but if there is some sort of major gap elsewhere I should be able to hear it.Last edited by bmwman91; 06-23-2020, 10:10 AM.Comment

-

OK, the issue is mostly resolved. The car runs, and I had a good time driving it for 30 miles, running it about as hard as hard as I could while keeping it under 5000RPM (I am going to put more like 100 miles on it before really revving it just to be sure the rings are worn in). It turns out that it was a software issue after all. I have a corrected high performance Sssquid tune in the car, which is what he has developed across something like 8 other 2.1L M42's from MM. After driving a turbo diesel for 7 months, I have to remind myself that punching the throttle at 2000RPM isn't going to do much haha.

With that said, the idle still has issues, but they are relatively minor compared to what I was dealing with. They seem to be heavily dependent on engine temperature. I have outright removed the LLCO wire from the Motronic connector, so I know it isn't that lol. Anyway here's where the idle seems to be at now, in the order that I encountered the issues:

1) The car did the thing where it stalled after running for a minute as I pushed the clutch in coming to a stop sign. It started right back up and did not do it again (for a while).

2) Once it was warmed up, it would stumble and catch itself as I came off the throttle approaching most stops, and it would intermittently exhibit a 800~900RPM hunting when sitting at idle.

3) I drove it to visit my parents, and it sat for maybe 30 minutes. When I got in to start it, it did not want to start. As it cranked it just barely gave an indication of a couple of attempts to fire, and a little throttle was needed to get it to actually start. The temp needle was a little shy of the 1/4 mark at this start.

4) As I slowed to turn in to my driveway ~20 minutes after #3, it stalled. I again needed to apply a little throttle to get it to start, and it stalled again when I let off the gas to park. I again needed to give it a little throttle to start it.

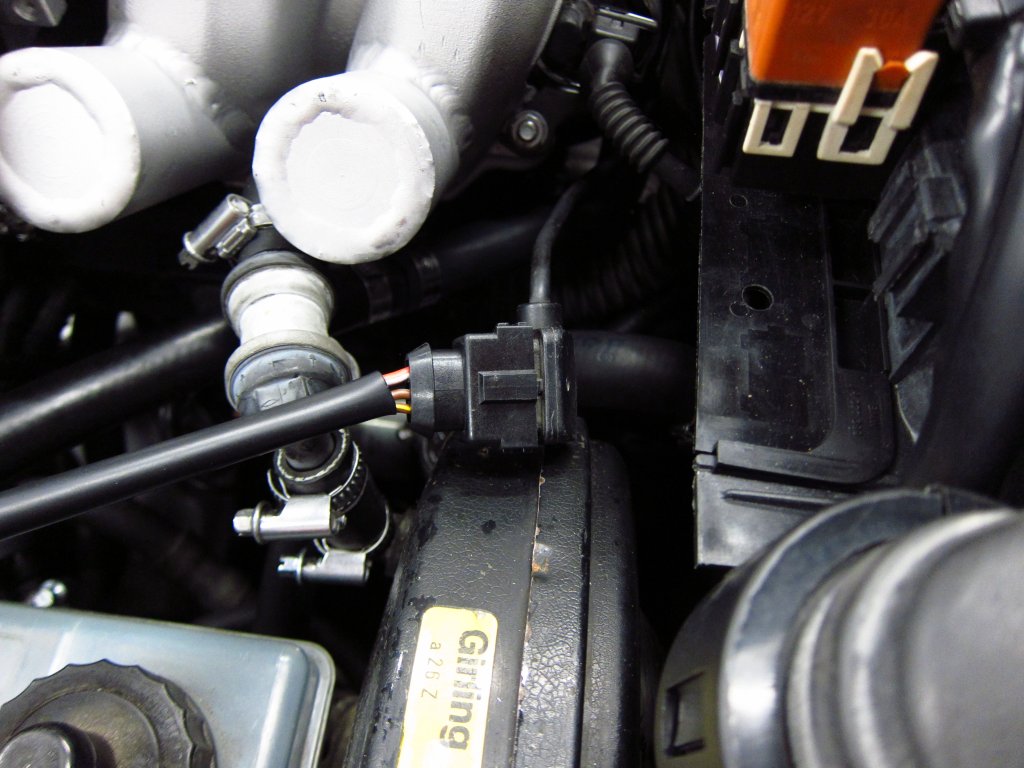

I still have the stock AFM in there, and it has the little extension harness / low-pass filter that BMW issued to most M42's at the time. I am replacing the CLT sensor when the new one comes in later this week, although the current one seems to Ohm-out just fine. Also, I assume that the super light RHD flywheel is not helping anything. I will still be re-checking for vacuum leaks and messing with bypassing the ICV as suggested since the above issues are a lot more similar to ones people have with more "common" faults in these cars.

For the record, the 7.4lb flywheel is fun as shit. Effortless rev matching, no weird noises at start (some people said that the RHD flywheel sounded raspy, but I do not notice anything) and crazy good response. To hell with the noisy rattling from the transmission, BMW should have shipped these cars with light flywheels!Comment

-

LTW FW generally will have a falling idle at a stop/clutch in when "too" light. And yes, any Getrag is a joy to drive with a LTFW, bit noisy as all get out. Not just BMW, you can Google "Getrag Rattle" and it's all makes/models - Dodge, Chevy, International...all of them....Comment

-

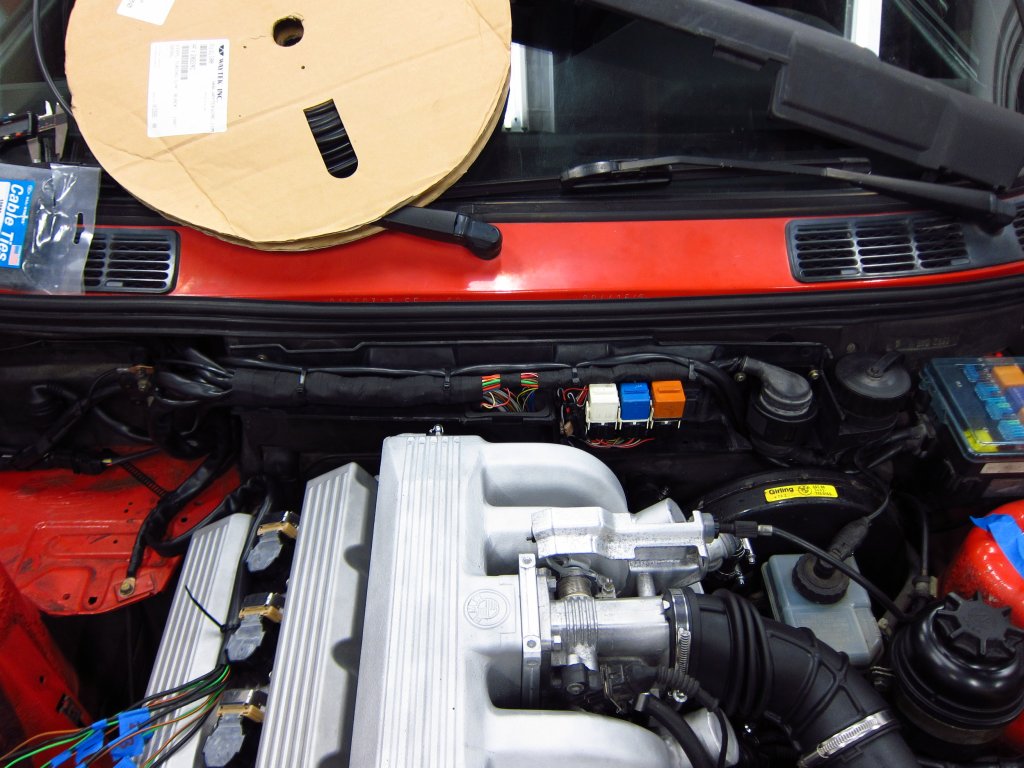

OK, as promised it is time for the photo dump of app the stuff I have done since the last set of photos.

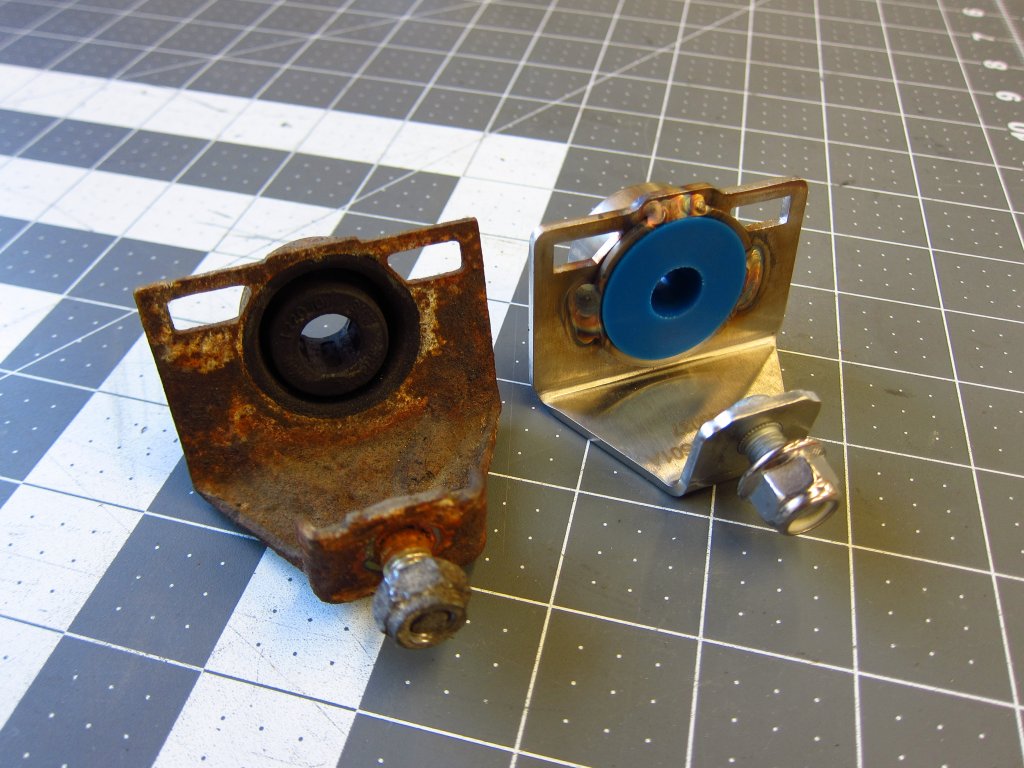

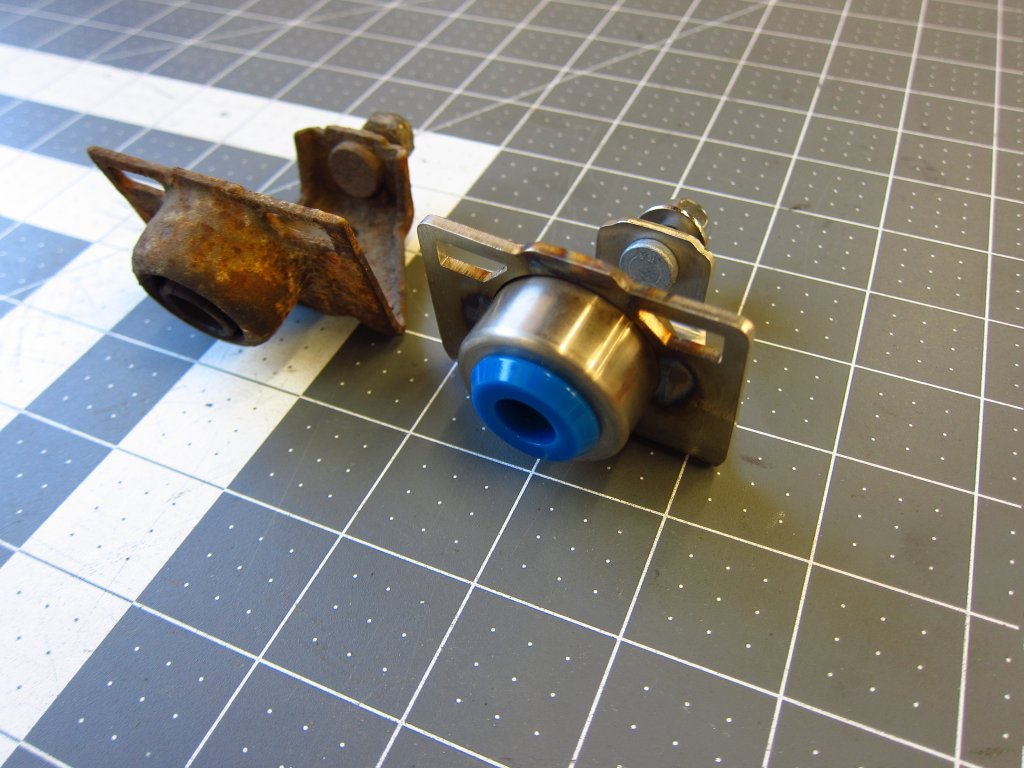

The rear shift carrier mount was in bad shape, and sort of expensive to replace, so I opted for the beefier Turner Motorsport upgrade. It was only marginally more expensive, and it would eliminate the last of the stuff in the linkage that was making extra slop. It does not fit exactly like the original one (the angle is a little different), but it is good enough to work properly. It was listed as being E30 compatible, so who knows.

I did make one small modification to the carrier. Rather than jam the mushroomed end through the new poly bushing (teehee), I just channeled my inner rabbi and filed it down. In normal operation the mushroom serves no function and just makes removal of the carrier more of a pain.

Here it is installed on the car.

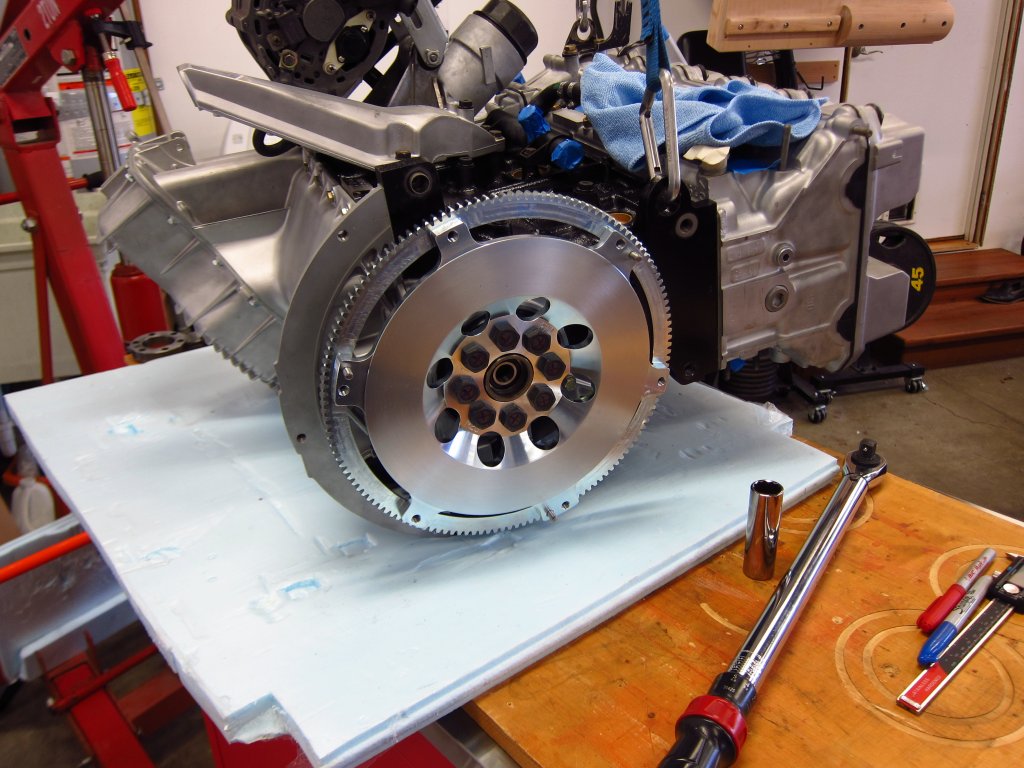

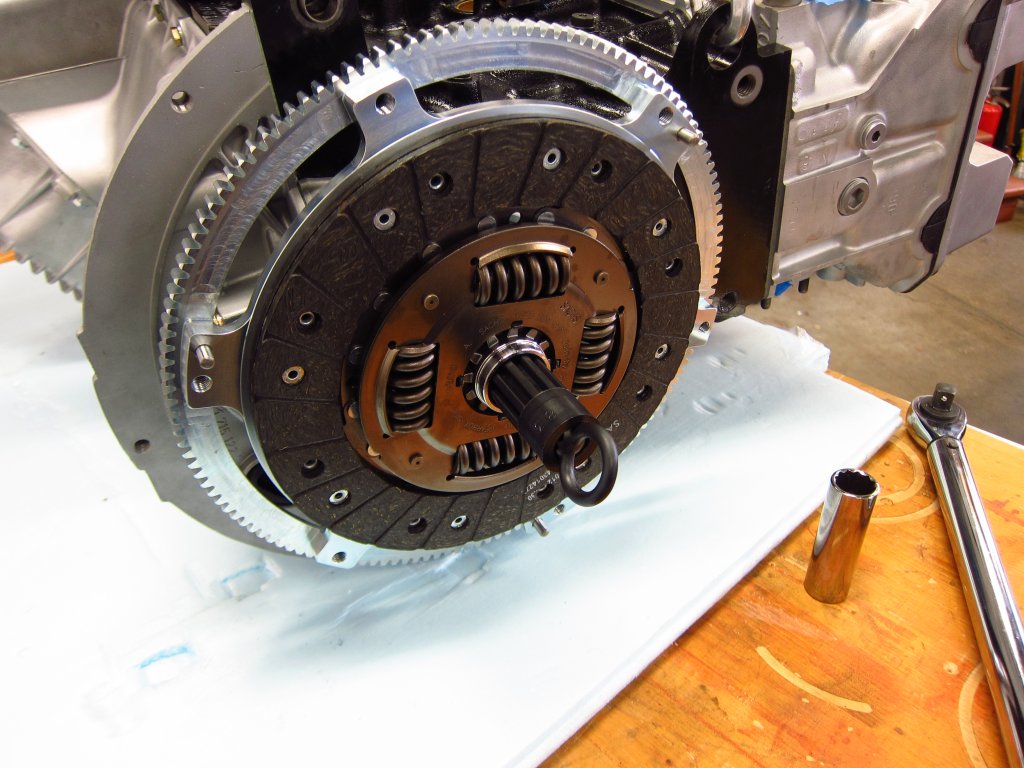

Here is the nice new 7.4lb RHD flywheel installed on the engine.

I also bought the proper crank locking tool, which is a hell of a lot easier to use than the big ½” cold rolled plate I drilled holes in 15 years ago. It was $85 at Pelican Parts. The weight of the engine was more than enough to keep things from moving around as I torqued the FW bolts to 120 ft-lbs.

Next up were the clutch disc and pressure plate. The FW and PP were dynamically balanced together and came ended up with <0.9 grams of total imbalance in the end. Cardelli Motorsports in San Mateo, CA did the balancing for me for $100 cash.

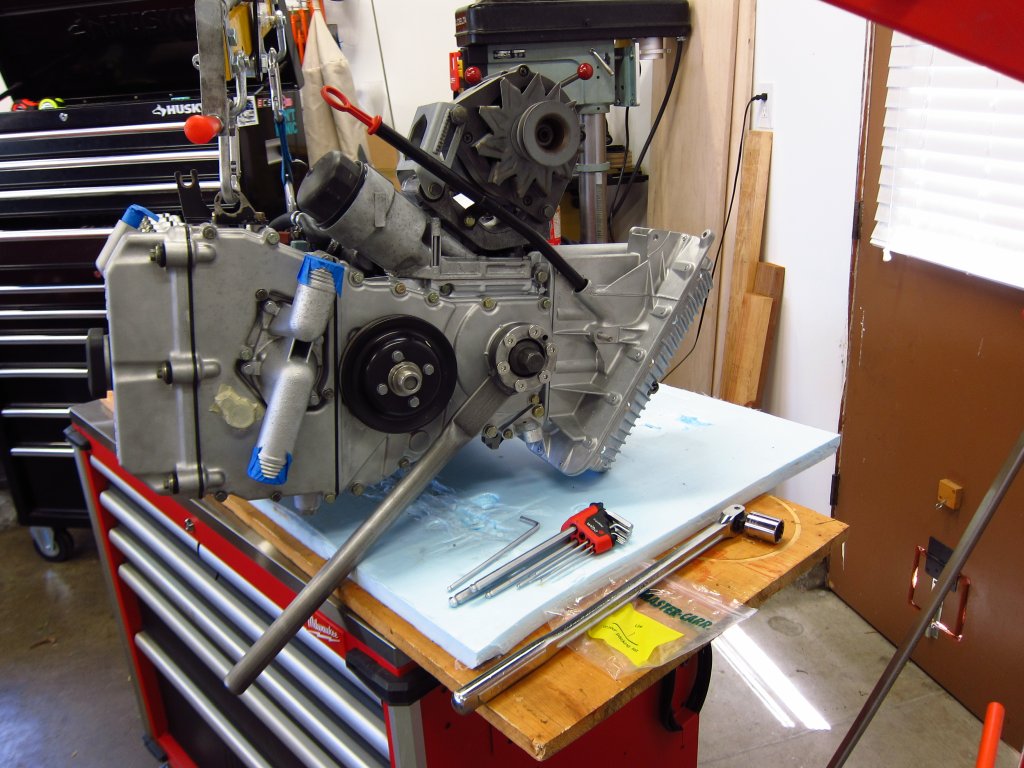

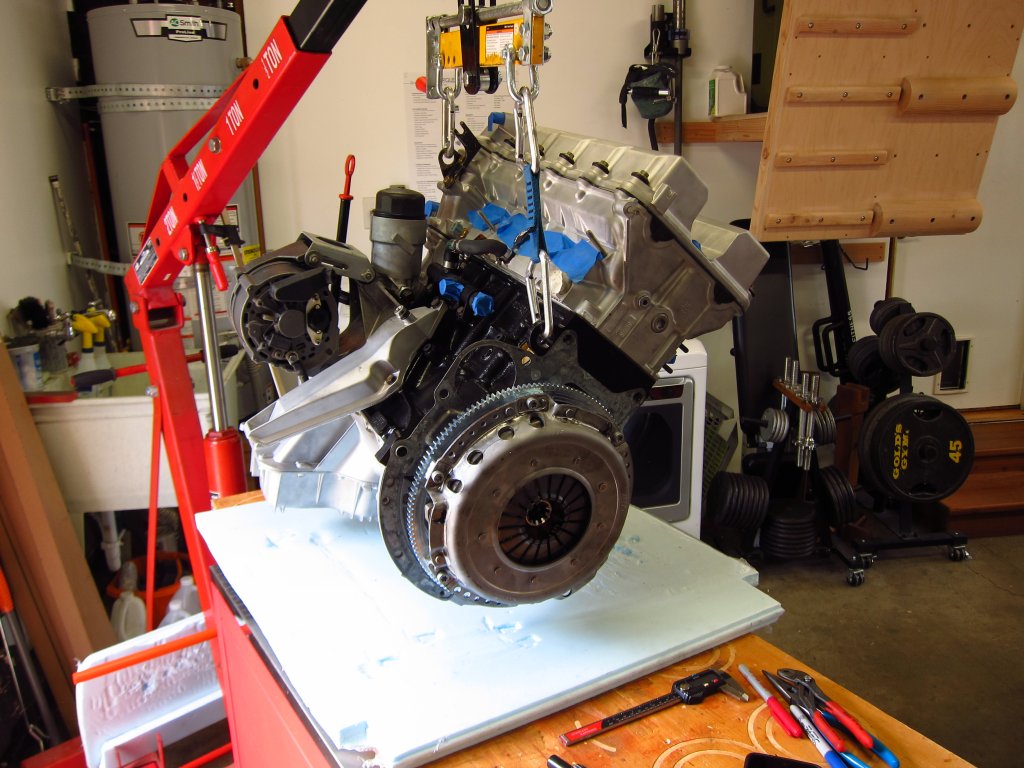

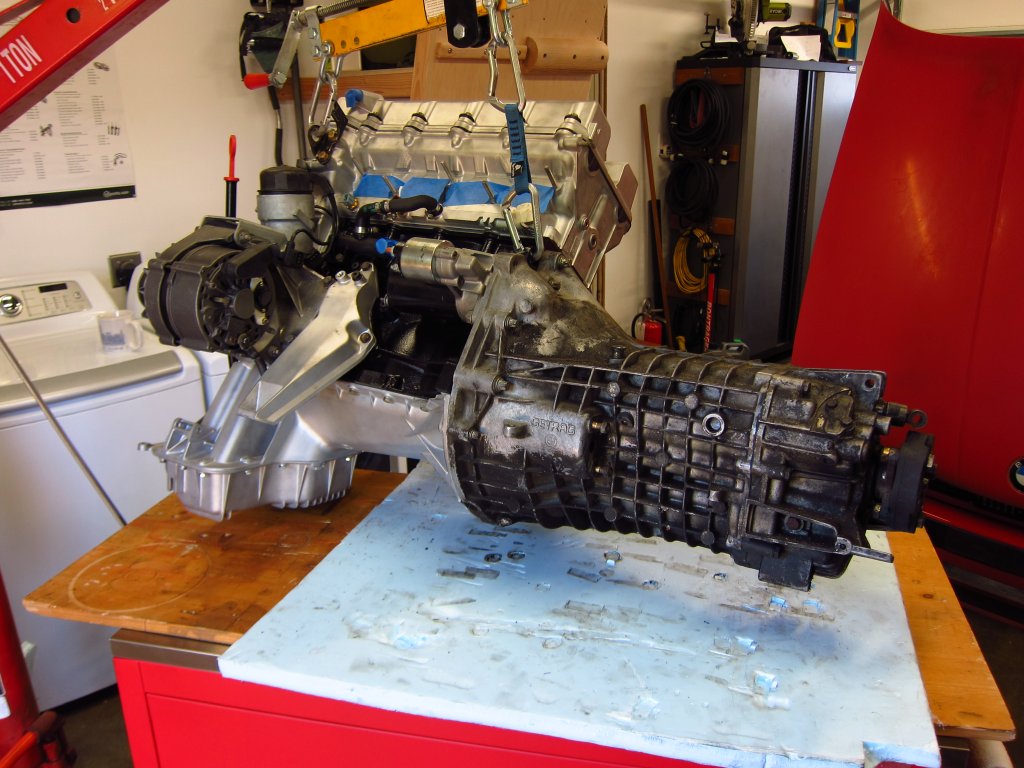

Next the transmission was bolted on. That was a super easy task with the engine up on the mobile workbench, and I got it to slide right into place. One hand to support it (so as to not load the pilot bearing excessively), one to start one of the big top bolts. And no, I did not bother cleaning the transmission. I had thought about it, but at that point I needed to get the project moving and out of the garage.

And there it was, mostly ready to go back into the car. It had a nice new ground strap as well. I replaced all of the ground straps (engine, alternator, hood) with new ones from Bavarian Restoration.

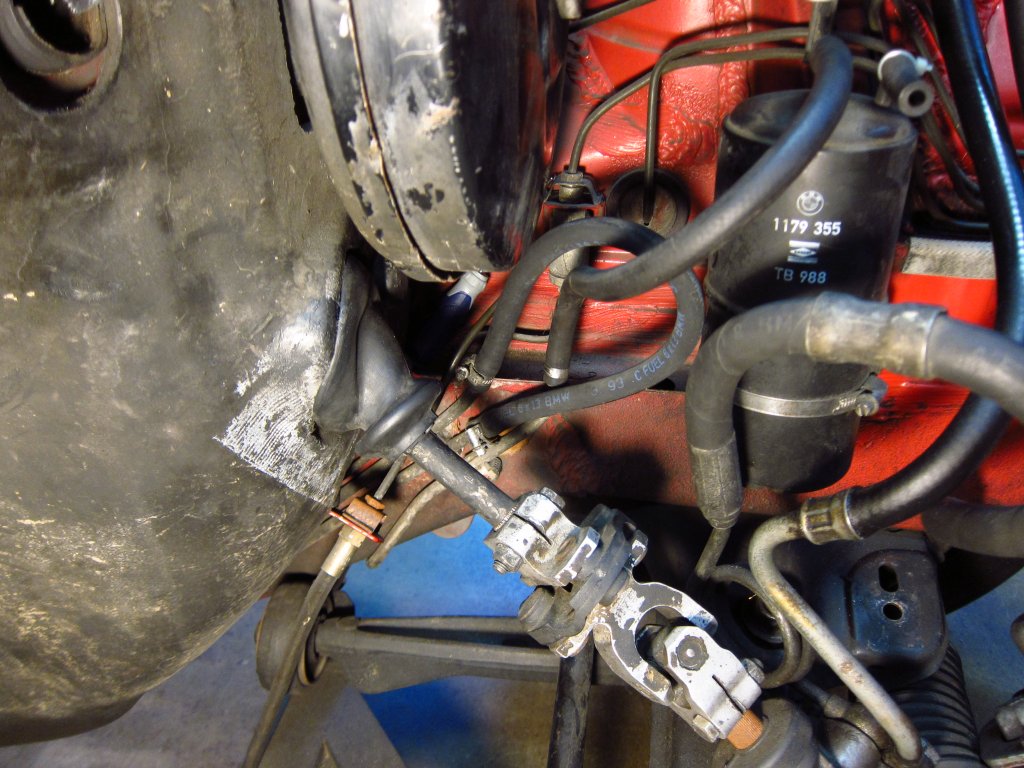

There were a few odds and ends to take care of before dropping the engine back in. Among them was purging the fuel lines that had sat for 7 months. This was pretty easy to do by looping the old feed hose onto the return hardline and hooking the battery up to the pump. If you hook the battery negative to the chassis and the positive terminal to C101 pin 13 (fuse box side) it will run the pump and have fuse 11 there for protection. I ran it for a few minutes and that was that. All flexible fuel lines up front were replaced with new ones.

Oh, and at some point I decided to cut my old flex disc in half to see how it is constructed. They are directional and need to be installed properly to put the proper parts into compression when applying engine power, leaving the other less stiff parts free for taking up vibration when engine braking. These things have some beefy fiber bundles inside (maybe aramid or glass, I did not check too closely).

Anyway, here it is plopped into the car. The main items to reinstall first are the engine mount arms and mounts and the exhaust header. That saves you from a bunch of reaching around under there, and getting the header in/out with the engine in place is a hassle. A few of the other accessories were also installed. Leaving the intake manifolds off, and having the entire firewall wiring tray out, made it super easy to get in. I almost did not even bump the engine or transmission into the car at all while tilting and lowering it in. In the past the main trouble spot has been up at the firewall where the intake manifold would hang up on the wiring tray (or the main wire loom).

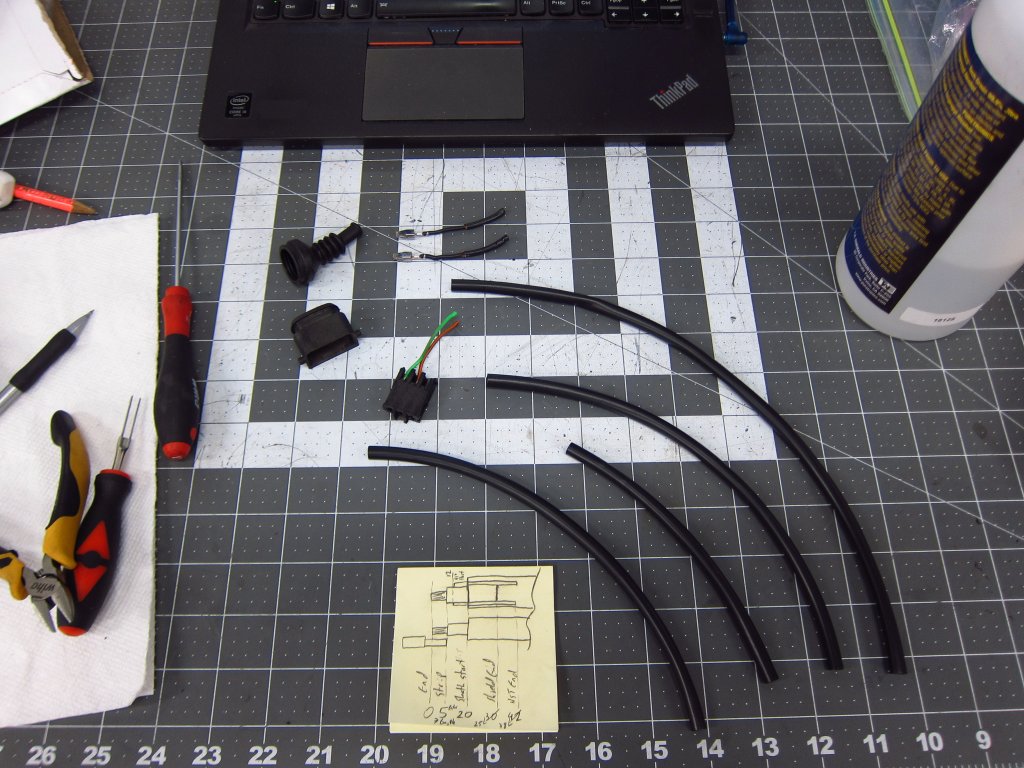

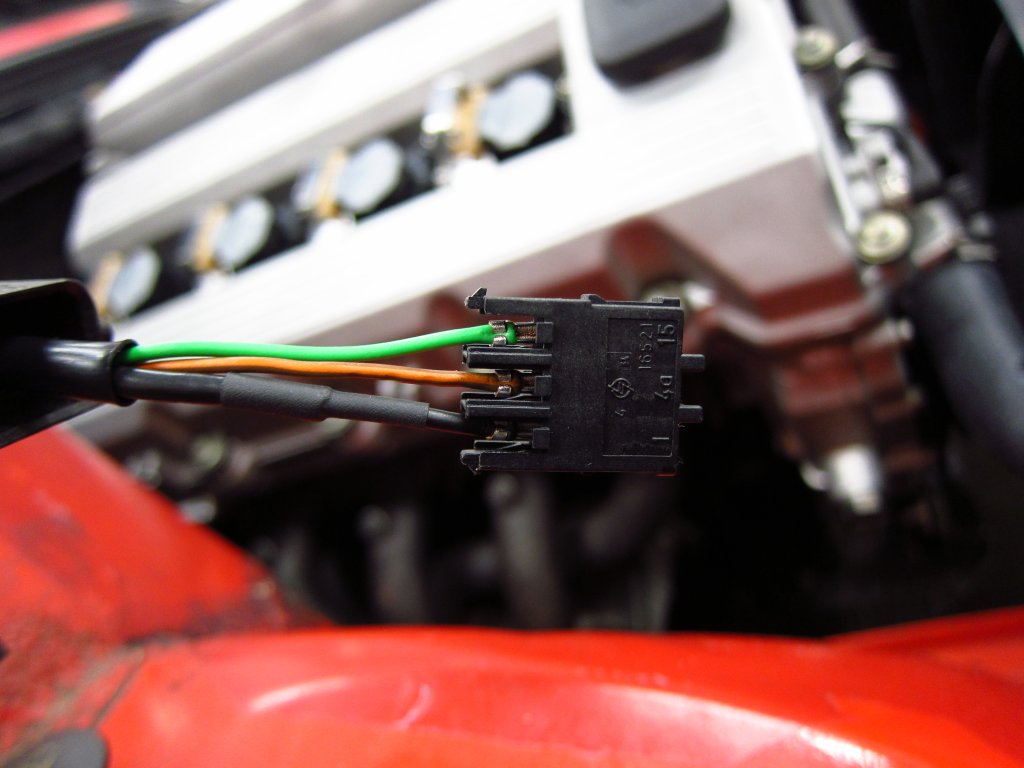

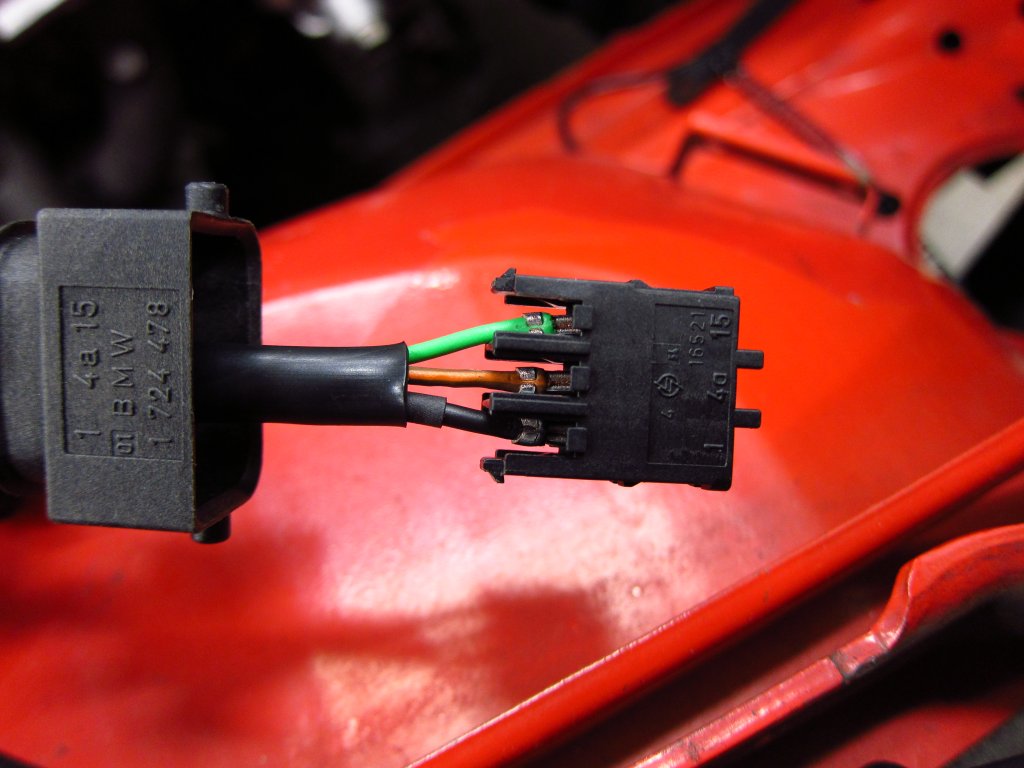

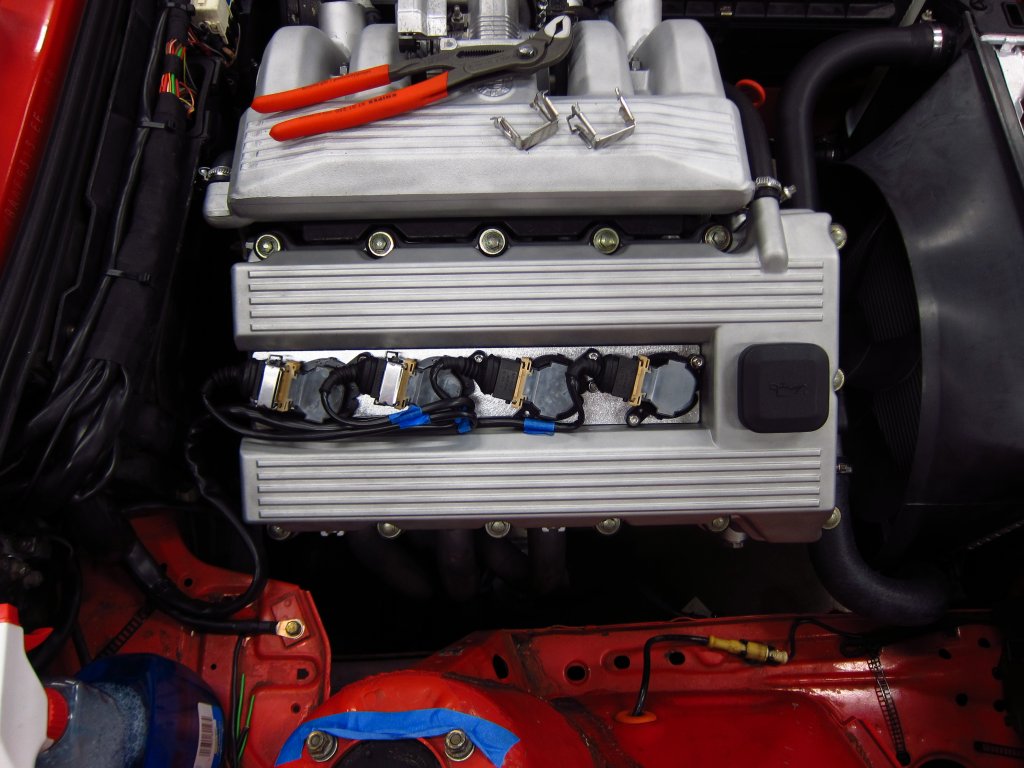

After bolting on some more stuff, I turned my attention to the engine wire harness that I had completely rebuilt. The final remaining task was to trim the ignition coil leads to their final length. I took measurements of the wires, where things were stripped, etc., on the original connectors and duplicated that with the trimmed ones. All of the sheathing is new since I changed up how the bundles route from the main loom on the firewall, and getting it all neatly in place was a bit of a chore. The main 0.56” ID sheath that the 12 wires for the 4 coils ran through split into four 0.25” sheaths, and to get clearance on the ends for the heat shrink tubing and stuff I needed to slide it all up into the main one. Windex for the win, it does wonders for enabling things to slide around while also drying quickly. Anyway, I am getting way too excited about wiring lol.

I started by figuring out how exactly I wanted to route the main bundle to give it a proper service loop for strain relief, and then I played with a few different configurations for the individual leads. The one I settled on worked out so that none of the smaller looms would rub on the metal plug retainers, none of the plug ends would be subject to any movement from the chassis loom and everything could be conveniently zip tied into place and serviced in the future. This is a COP plate kit from HQ Autosport, but I made some changes to the fasteners and added some washers as spacers for ergonomic reasons (maybe I will do a write-up of how I improved upon it sometime).

OK, I will try not to type another giant paragraph about wiring. As much of a pain as it is, it is sort of fun if you are doing it right.

Once things were roughed into place, I cut the leads and sheath pieces I would need. From there it was just a matter of crimping the terminals on and putting the connectors together. As another FYI point, the rubber boots for these connectors are a real pain in the ass to get onto the 0.25” sheathing. It is the same diameter as the original sheaths, but the boots are either not intended for use on that size, or they are supposed to be REALLY snug. Getting them onto the sheath was a bitch…be warned!

Here it all is laying in place before I actually finished it up.

And here is the final setup. I am pretty pleased with the little service loop that connects the chassis to the engine. Compared to how I trimmed and routed stuff on the old harness back in 2006 when I invented the COP conversion (fun fact!), this is immensely better. Considering that shitty wiring job lasted 14 years with no broken wires or pierced insulation, this should outlive me.

And so, here it all is today. I have ~160 miles on the engine and have been driving the dog shit out of it. Damn it is fun, and despite being able to feel the car’s age, it is a hell of a lot more fun than most newer cars. All drivetrain and suspension stuff is effectively new, but it’s still based on 40 year old automotive design, so the way it handles and reacts feels a little dated. BUT, it is a go-kart compared to heavy newer sports cars, and despite being slower it has a feel that you don’t get anymore. I had mostly forgotten how much I enjoy driving this thing over the last 7 months of waiting and toiling!

Other random crap….

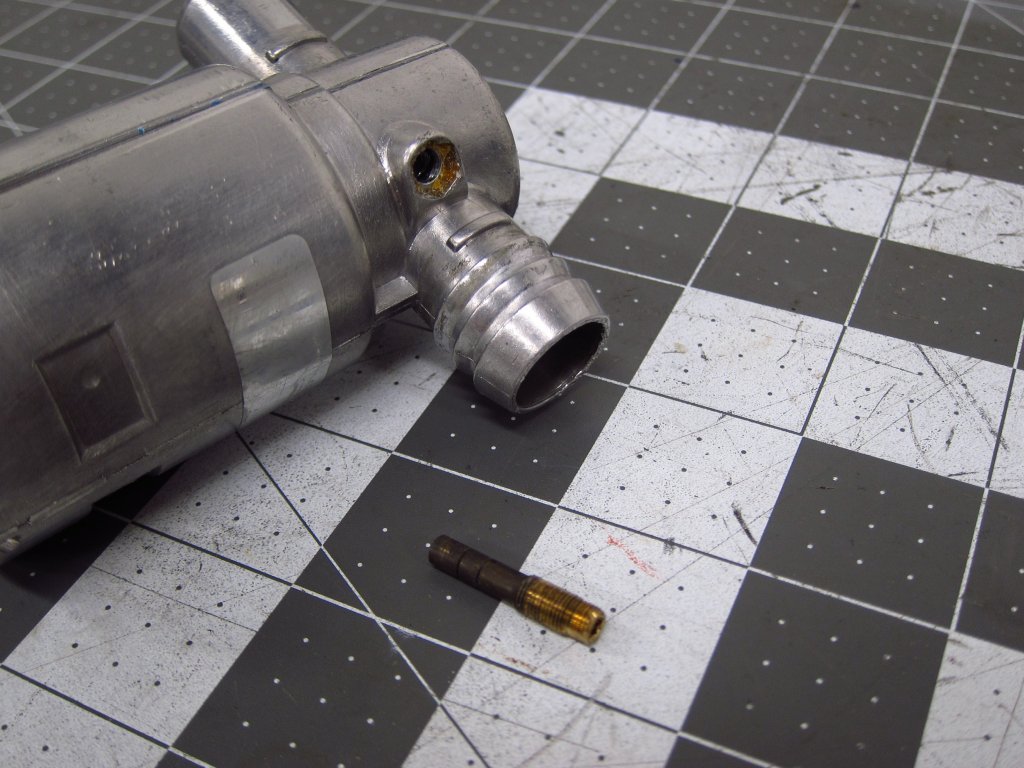

As you all have seen, I was chasing down gremlins as I tried to get it to run. Since roguetoaster sold me an ICV that was in cleaner shape than my old one, I decided to dissect the one I took out. I’ve never seen one opened up, probably because you have to totally destroy it to get it apart. The outer housing is staked in like 10 places (both the end, and on the sides) and one part is pressed in. Ultimately it is just a simple little electric motor. The design is sort of unique, and clearly not intended for high torque, but it works well enough. The single coil that makes up the stator interacts with the magnetized center cylinder and funky-shaped upper section that serves as a rotor of sorts. The I assume that the shape of the ferrous top is what allows it to interact with the symmetric magnetic field from the coil (I wouldn’t expect it to generate motion at first glance, were it not for the wedge shapes at the top which you can sort of see in the next pic).

This set screw (which is epoxied into place) sets the end stop for when the thing is not energized. It leaves the ICV open an amount that corresponds to the engine’s air needs at the designed idle speed, hence why unplugging it usually leaves the car idling reasonably well.

This little flag is the thing you see moving through the hose barb. The ECU sends a 100Hz PWM signal to the ICV, and this little door flaps open and closed at that rate. Varying the on/off time in that 100Hz signal is how the “average” opening amount is created by the ECU to control idle (Motronic also uses enrichment and ignition timing to control idle speed and stability).

Back when my fuel injectors were stuck shut, I tried to free them with a programmable power supply (you can program voltages and on/off times to make a pulsed output). I also had some spare wire harnesses that were cannibalized to rebuild the one in the car, so I took more parts from them and made my own little debug connectors for the injectors (and some other stuff just in case).

Phew…there it all is. Things are mostly wrapped up now, and I will make new threads for the other non-rebuild stuff I came across in this project. I’m going to cross section one of my old ignition coils for fun, and probably take apart the old MAF sensor element. Mostly I need to remember to make a DIY for how to improve the HQ Autosport COP bracket kit, and try to get measurements of the wiring dimensions. Granted, many of the measurements are useless unless you totally rebuild your harness since the stock ignition coil wire routing won’t leave you enough length to do it my way.

Thanks a lot to everyone for all of the input, encouragement and discussion over the many months since this all started! The E30 community is probably the #1 reason why I still have this stupid car lol.

Comment

-

Congrats,. Great work and documentation. I probably missed the info elsewhere, but what are the modifications to the upper intake manifold?Comment

-

Comment

Comment