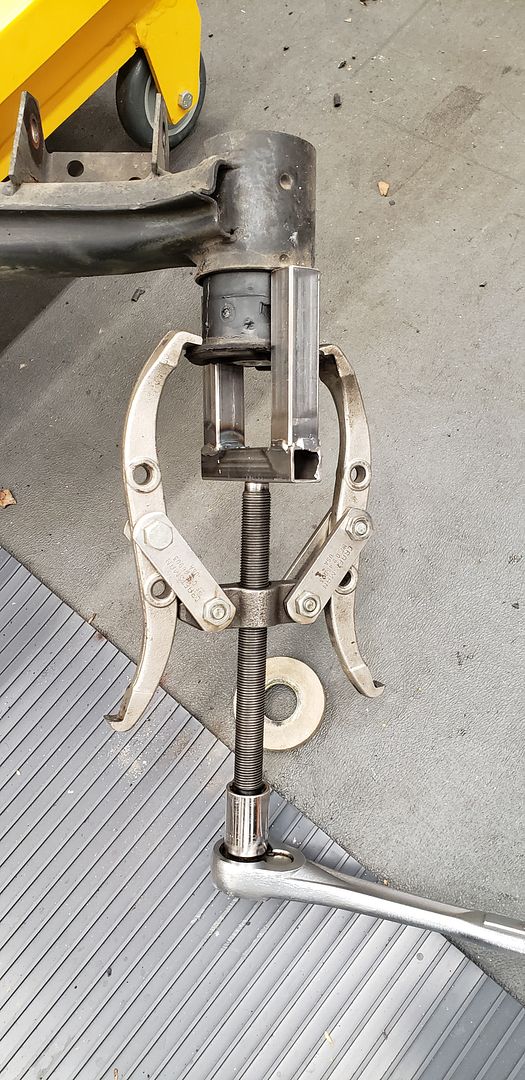

I used a threaded rod to get it part way in then a 2 jaw to push it home. With threaded rod I used a bearing puller spacer/puck between the body and sub frame beam so the threaded rod went through hole of the bearing spacer so it was nice and solid so the force was transferred into the bush

Subframe bushing removal

Collapse

X

-

89 E30 325is Lachs Silber - currently M20B31, M20B33 in the works, stroked to the hilt...

new build thread http://www.r3vlimited.com/board/showthread.php?t=317505

-

I don't know how you got this to work. When I tried it, all I did was bend the lip on the subframe bushing and then my 2 jaw puller slipped off the old bushing.Comment

-

Lots of heat and threaded rod with sockets attached. You'll get it eventually, then have a well deserved cold beer

Sent from my SM-G973U using Tapatalk

Comment

-

Having done subframe bushings 3 times now, I have some thoughts.

1. Unless you can borrow the BMW special puller tools, drop the whole subframe. If you are replacing the subframe bushings, you will probably want to do trailing arm & diff bushings while you are at it. Dropping out the whole rear subframe assembly is honestly easier than trying to do it on-car. Just make sure to cap the flexible brake lines with something that brake fluid won't destroy...if the brake lines drain out completely it might make bleeding a hassle if air gets into the master cylinder.

2. I've removed bushings both by burning and slitting the outer metal sleeve. The fire solution is toxic and will mess up the powder coating on the subframe. Cutting the sleeve is a lot of work, and carries a risk of damaging the subframe. Last time I did this job, I just paid an auto shop to deal with it on their press.

3. Installation. I have turned my own tools using iron pipe fittings & Acme threaded rod in the past. That worked OK, but I think that I was about 1Nm away from shearing the rod by the end lol. Last time I did the bushings, I just took the subframe to an auto shop and paid $100 for them to press the old ones out & the new ones in. If you DIY it, you want to use bushing installation lubricant of some sort. Dish soap and water works OK as a DIY installation lubricant.Comment

-

Having done subframe bushings 3 times now, I have some thoughts.

1. Unless you can borrow the BMW special puller tools, drop the whole subframe. If you are replacing the subframe bushings, you will probably want to do trailing arm & diff bushings while you are at it. Dropping out the whole rear subframe assembly is honestly easier than trying to do it on-car. Just make sure to cap the flexible brake lines with something that brake fluid won't destroy...if the brake lines drain out completely it might make bleeding a hassle if air gets into the master cylinder.

Thats why I bought the tool years ago and now rent it. Best $50 anyone can spend imho opinion. Can even be used while on the car. Did my e28 like that.Alex 88 m5 | 91 318is | 19 Subaru Ascent

BMW Tool Rentals & Fender RollerComment

-

I tried the floor Jack method tonight. Froze the bushing and coated the bushing and frame in silicon spray. Didn’t work. Only lifted the car. Going to build the threaded Rod version to pull the bushing into the car.

i was wondering. Every build has a socket then washer then nut to pull the bushing into the car. Why not just use a washer?Comment

Comment