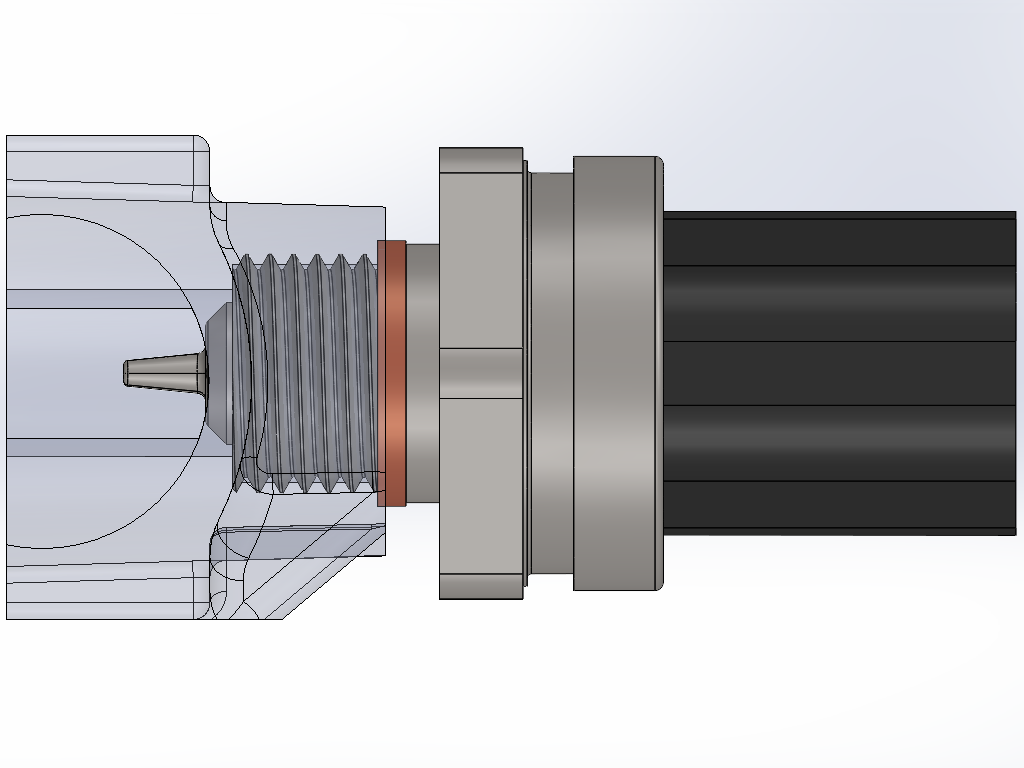

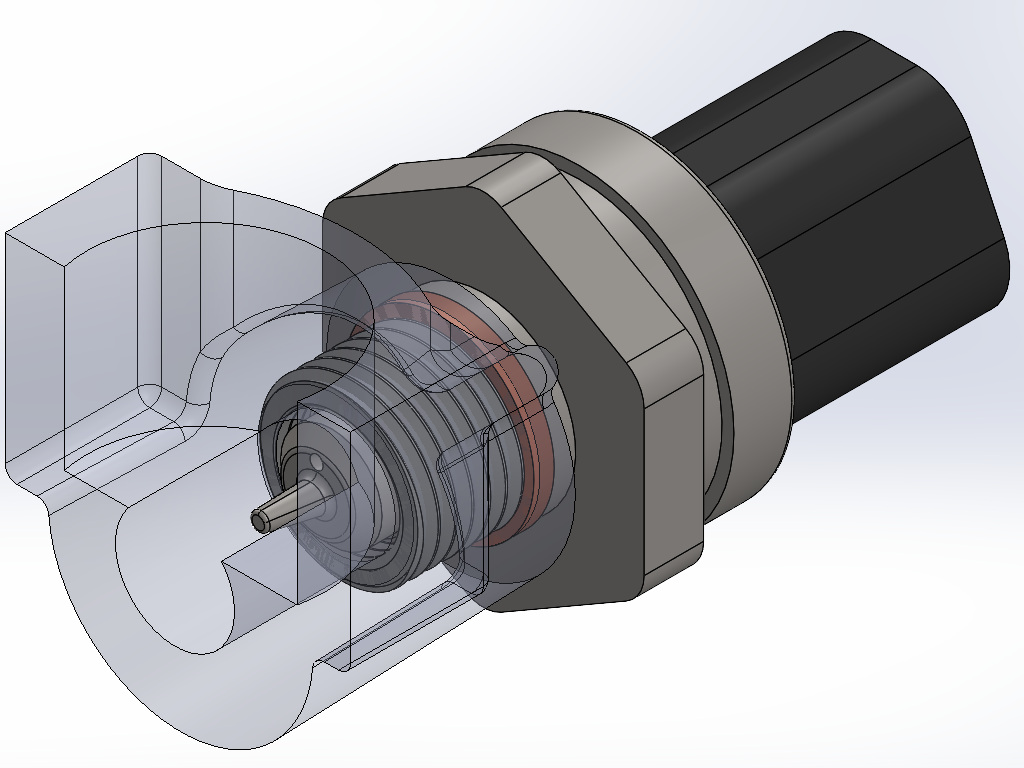

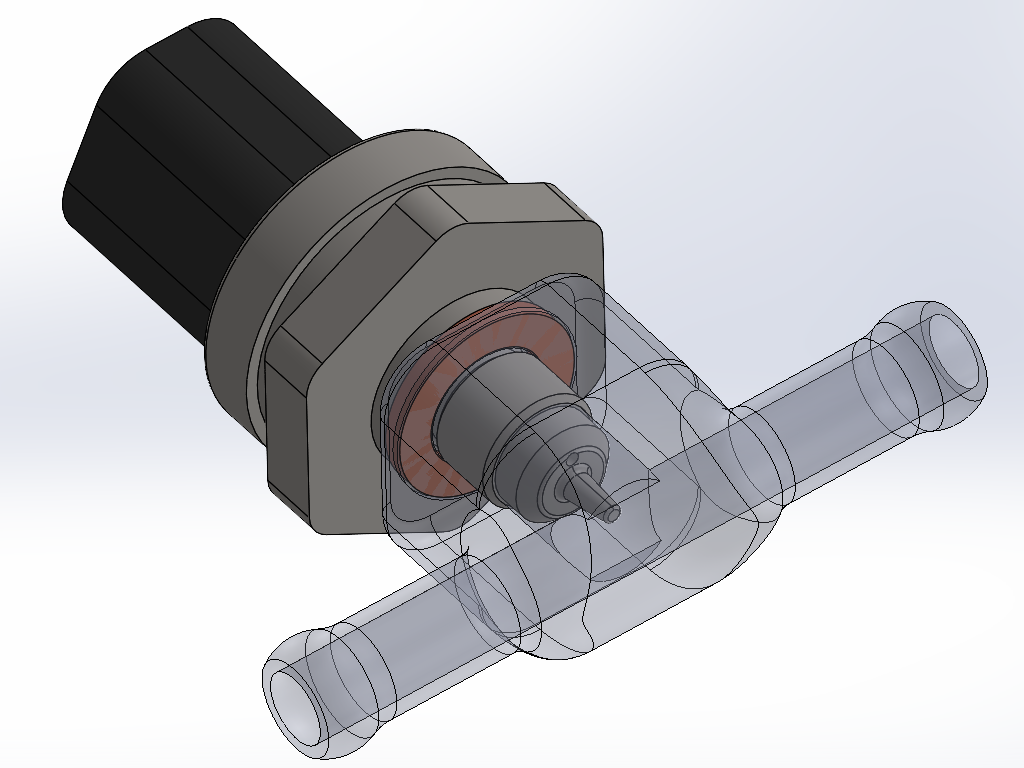

So with a little trimming that can all be done pretty easily on a manual mill, here's how the sensor will end up fitting in there.

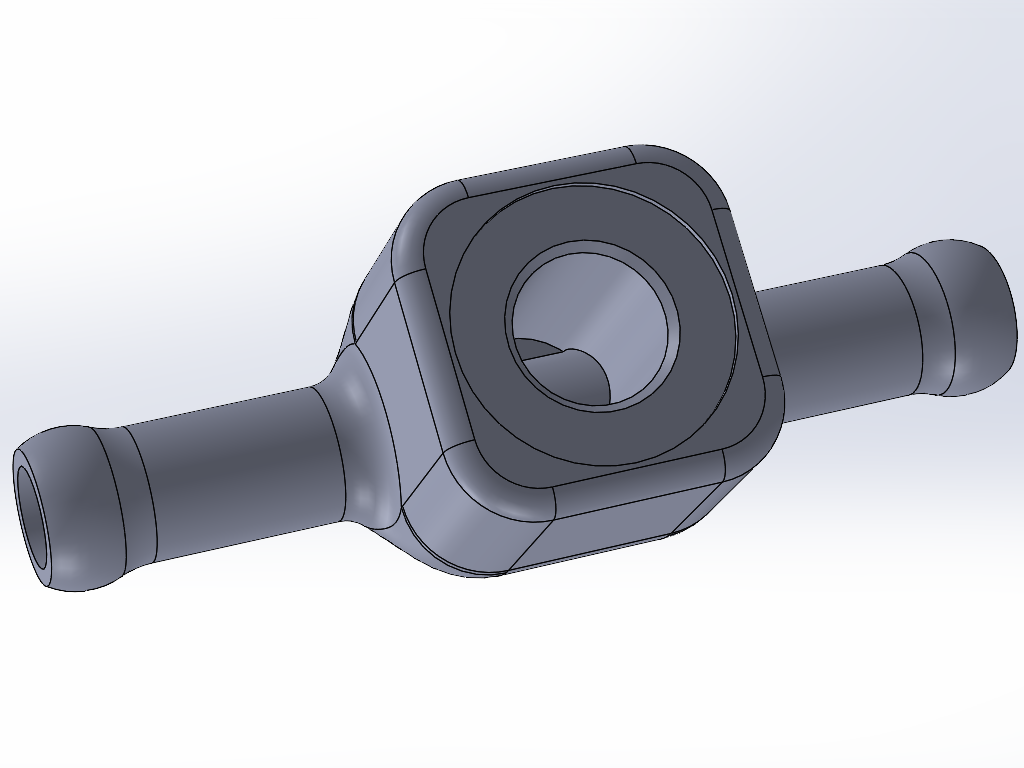

For the fuel sensor, I am planning to have a little inline tee fitting CNC machined from some 7075 aluminum rectangular bar stock I have laying around. This will install into the 8mm ID hose that feeds fuel into the rail, as close to the rail as I can get it. I'd expect the fuel to heat up minimally overall since it flows at a fairly high rate and has a lot of metal tubing to dump heat from between the front & rear of the car, and it probably does not spend enough time in the rail to significantly heat up much more after the sensor, so I figure I will get a decent reading of it like this. The other option was to get a spare fuel rail and have a friend TIG a little threaded boss onto it, but that seems very unnecessary, and would be a pain in the butt to access if I needed to replace the sensor.

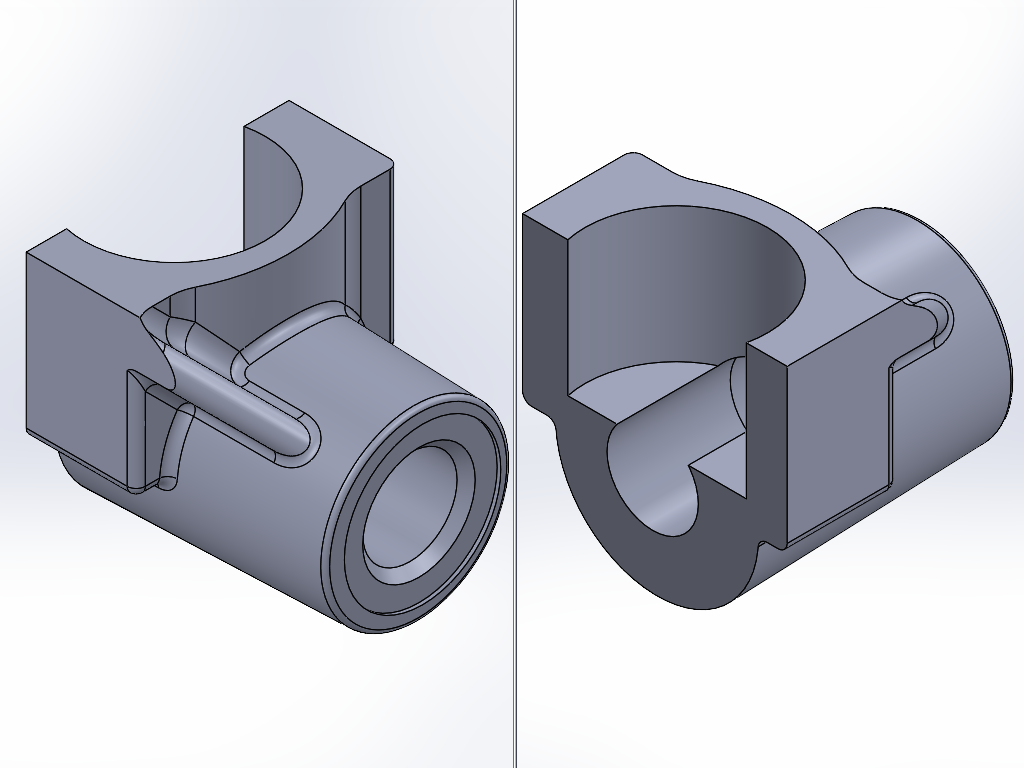

The other open items I have are to figure out where & how to mount the M50 ICV, and how to mount the MAP+IAT sensor. I'd like to fit the ICV in approximately the same location as the original, but it is pretty tight and will likely require even more custom machining. The other option is to mount it vertically in the open(ish) area behind the intake boot and a little to the left of the intake manifold. For the MAP+IAT, I am thinking I am going to mount it on the rear-most sloped face on the top of the intake manifold since that is the only spot I where I am confident that it'll clear the hood insulation. Maybe I will try sticking some foam blocks on the top flat part to see if I can clear the insulation closer to the middle, but it seems iffy. Either way, it needs 9~10mm of material thickness to get a seal with the o-ring it uses, so I will need to machine a little mount plate or flanged sleeve or something.

Leave a comment: