Panici's '87 325is E30 - Boosted In Bronze

Collapse

X

-

Rear Ended Yesterday...

Parked at the side of a quiet side street. Sitting in the car tuning the ECU for altitude compensation.

Rear ended by a lady not paying attention.

As you can see in the pics the pillar is tweaked a little. Opposite side popout window also doesn't open without forcing it.

Car seemed to drive straight around town at least...

Would be very surprised if insurance doesn't total the car out. This may be the end of this thread :(

Still waiting to hear from my claims adjuster.

Was in the ER until 3am, I checked out OK physically, with a sore neck and back.

Emotionally I am obviously distraught. Six years of careful work destroyed in an instant.

I will save the car if I can.

Last edited by Panici; 09-30-2020, 06:51 PM.

Last edited by Panici; 09-30-2020, 06:51 PM.Leave a comment:

-

Driving, Tuning, M50b25 Manifold

Have been enjoying driving & tuning the car. Wired in my speedo to the ECU, so now I have gear detection.

This let me set up some trick features like a leaner AFR map when in 5th gear and under 30% throttle for fuel economy.

Also hijacked the ebrake wiring, using the dash light as an output from the MS3X, and the switch as an input (activates on two clicks up, before the ebrake shoes engage). Currently configured to change my spark map to one without overrun burble.

Swapped in an M50b25 manifold. First attempted to use an M50b20 manifold unknowingly (seller didn't know either apparently). Lucked out and found an M50b25 manifold local-ish and repeated all the tweaks needed to fit it. Made my own bracket and vac hoses, which surprisingly don't leak, except for where they connect to the manifold (common issue).

Just turned down the idle valve duty and that sorted the problem.

Deleted the traction control throttle body.

Also installed the dual MAP sensor mod in the ECU for altitude compensation.

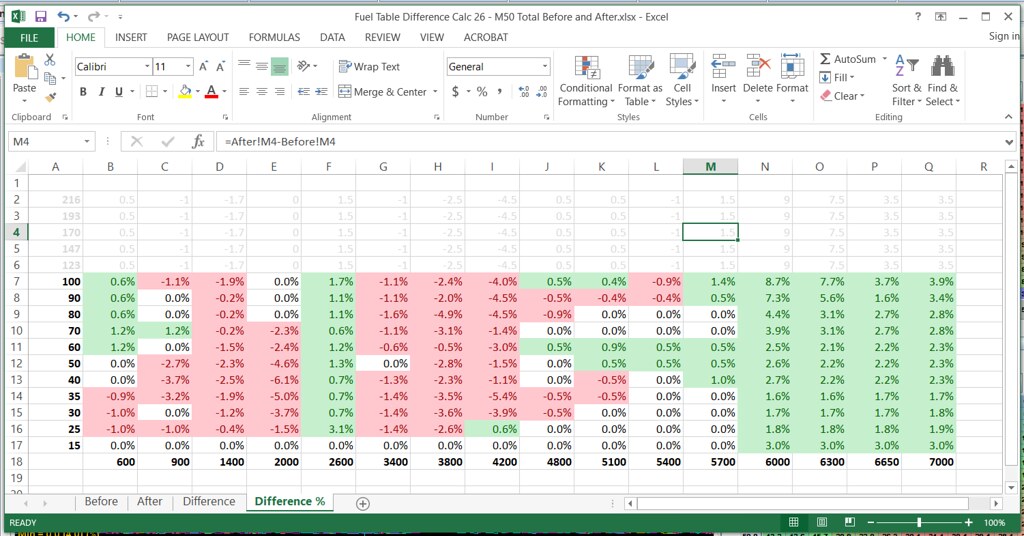

I'm not finished tuning for the M50 manifold yet, but here are my VE table changes so far. You can clearly see where it lost power in the midrange, but gained a whole bunch up top!

Last edited by Panici; 09-30-2020, 07:14 PM.

Last edited by Panici; 09-30-2020, 07:14 PM.Leave a comment:

-

Are you going to make a heat shield in the engine bay for the intake, or are you going to just ignore it until you turbocharge it?Leave a comment:

-

Wheel Testing, Intake Air Temp, Altitude Changes

Driver's side BECK/ARNLEY brand hub/wheel bearing stripped a lug bolt hole on the first wheel change.

Attempting to return to Rockauto, meanwhile have bought and installed a MOOG replacement.

Test fit a set of ROH Eurosport 15x7 wheels. Will be using these for the Miata, but wanted to see how they looked on the E30.

Tires are too small (honda fitment) so it throws off the whole wheel gap situation, and I didn't have big enough wheel spacers to get them sitting nicely relative to the fenders.

The look certainly is different (not sure if I like it or not) but I've already taken the wheels back off.

Noticed both heat soak and very slow response from the OEM OBD2 MAT/IAT sensor, so I installed a GM Open Element IAT sensor.

This new sensor made me aware that I was running 140F intake air temperatures.

Given this tuning opportunity, I set up my MAT-Based Timing Retard table to pull some ignition if intake temps get too hot.

Starts pulling timing at 130F (1°), and by 180F is pulling 6°.

After some experimenting I found that the filter was sucking hot air right off the back of the radiator.

Since I'm not running a hood right now, I swiveled the intake tube to get the filter up into clean air.

Used some spare parts from the E39 M52 intake boot to make the IAC hose connect up properly.

This brought my intake temps down to ~90F.

That 50F drop in IATs (and corresponding increase in air density) equated to 5% more fuel once I tuned my MAT Air Density table.

Obviously this isn't a permanent addition to the car, but it's fun for now!

Tuning is coming along nicely, I have my fuel map close to perfect now.

Tried adding in some more timing, and was getting near the Pazi88 timing basemap.

Car pulled hard, but I have backed off the timing again for now to be on the safe side.

Trying to get better data from my Knock sensors, have ordered an electronic mechanics stethoscope which I plan to modify into a set of det cans.

This will be another tool to help get the timing dialed in.

I've got a rough configuration in my AFR safety system. This shuts things down if the motor goes too lean under power.

Usually used for boosted applications, but doesn't hurt to have for N/A.

Went to visit my friend Jeremy to ride some dirtbikes, and took the E30 on its maiden long-distance trip with the new motor.

About 2.5h of driving each way, and I only ran into issues when going up in elevation.

Saw 15 on my AFR gauge when cruising, and busted out my laptop to add some fuel to the whole table.

I found out later that due to the way the MS3X calculates fueling with the single MAP sensor, the car leans out when going up in altitude.

I've since ordered a dual MAP sensor mod for the ECU (dubbed Mapdaddy) that can measure ambient pressure, so you can tune the ECU to compensate accordingly.

This mod also upgrades my main MAP sensor from 2.5bar to 4bar, which gives plenty of sensor headroom when I turbocharge.

I was impressed with my average fuel economy of 9.2L/100km (25.5MPG) on the trip, considering I wasn't driving for economy.

That's markedly better then the M20B25 with the Dinan chip I was running previously.

Since I had the laptop out it was kind of cheating, as I was able to lean the cruise out on the fly.

Car sat overnight in a rainstorm with the hood off (covered the air filter).

On the drive home the clutch engagement point was noticeably closer to the floor, so I thought I got water or air into the system somehow.

Once I got safely home and into the garage, I tried pulling the clutch up with my toe, and now it seems to be operating normally with the usual engagement point.

Jeremy 3D printed me a vent gauge pod, and I moved my wideband gauge. Much better spot for it here compared to the ashtray.

I'm not sold on the aesthetics, but it works for now.

Last edited by Panici; 07-21-2020, 06:00 AM.

Last edited by Panici; 07-21-2020, 06:00 AM.Leave a comment:

-

Thanks! The tall 15" tire sidewalls definitely adds to the ride comfort compared to larger wheel setups.

Currently running 5mm front and 15mm rear spacers with the Euroweaves.

I have played around with a set of 10mm but they looked a bit too wide in the front.

Could probably get away with 20mm rears but I don't have a set to test with.

Leave a comment:

-

I can't remember, are you running wheel spacers or are those just stock euroweaves?Leave a comment:

-

Radiator Hoses, Wheel Bearings, Tie Rod Ends

Swapped out my cobbled together radiator hoses for two of the Gates 21794 which I cut to fit.

I also got a much better bleed on the system; It's no longer riding the SPAL fan for dear life to stay cool!

Changed my front wheel bearings on both sides, passenger side was starting to get loud, but they both needed to be done.

Still waiting on new front axle nuts and bearing caps (in the mail).

Bought some E36 outer tie rods, which let me switch to the brand new E36 inner tie rods that came with my Z3 steering rack. Along with the new wheel bearings and an eyeballed alignment the front end feels nice and planted now.

Still working on my tune as well. Started to dial some timing back into the map, and working on leaning out the cruise areas for fuel economy.

Bonus picture of the Miata from the other night.

Last edited by Panici; 06-30-2020, 07:16 AM.Leave a comment:

-

Tuning Accel Enrich, Upper RPMs, Overrun Burble

Turned on Accel Enrichment (AE), and got some base settings for the Accel-Pump mode from someone on Boosted E36 World facebook group.

Turns out his curve of fuel vs TPSdot is completely different then what I would end up using, but at least it gave me a starting point.

Here is a video and corresponding log of some revs when I first turned the AE turned on.

You can see the big knock spike on the first tip-in from idle, and see the CEL flash in the video at the same point in time.

I found that the wideband can't respond fast enough to see fueling changes made by AE in real-time, so a lot of the AE tuning was done by trial-and-error, making changes and feeling how the motor responds.

I know there are better methods to tune AE, but I've now got it in the ballpark.

Here is the curve I'm currently using. No more tip-in knock, throttle response and drivability are both good.

I was getting misfiring at RPMs over ~6000, so I gapped the colder NGK BKR7E from .030" down to .027".

Along with trimming my fuel out in that rev range, the issue is almost resolved.

I also added a fat ground wire from my Quadspark modules to a clean & bare chassis point, further away from the ECU grounds.

I'm going to try adding some timing back in, as i'm still 5-6 degrees below my base map in that area.

(Picture of plugs when they were gapped at .030")

Here is my current fuel/VE table. Keep in mind that the bottom row is 15kPa (Overrun), and top half is untuned boost areas. It's quite an improvement compared to the one in my previous post.

I'm starting to play with timing in the 15kPa area as well, aiming to get some nice burble on the overrun without getting too crazy into the pops & bangs territory. Currently at 1.8deg timing in that bottom row.

You can really see how the Volumetric Efficiency (VE) drops off in the higher RPMs. That's a great visual showing how restrictive the M52 intake manifold is at higher rev ranges.

Last edited by Panici; 06-22-2020, 02:19 PM.

Last edited by Panici; 06-22-2020, 02:19 PM.Leave a comment:

-

Tuning Details, Cleaning Carbon, Relocated Spark Boxes

Had a miss on cyl 3 so threw in a set of new sparkplugs (NGK Iridium IX BKR6EIX - 6418) which sorted the issue.

Some details about my MS3X standalone ECU learning process:

I've never done any engine tuning or mapping before, so there is a bit of a learning curve to say the least!

Thankfully I had a base map which helped me get the motor running back when it was on the wood blocks.

I started off by adding a bunch of fuel and pulling a little spark uniformly from the base map.

Then I sorted out my open-loop idle and mid-throttle fuel map.

Started on my WOT fueling, and then came across a few things.

I set up my CEL to come on when the knock sensors pick up more then 40% noise. This isn't necessarily knock, it depends on how the sensors are configured (supposed to be done on the dyno), and how noisy the motor is when revved up.

I have my threshold to start pulling timing automatically at 55%.

I noticed I started out with the CEL just barely flickering around 4500rpm at WOT, but as I started to pull fuel out from my 10-11AFRs it would light up a bit more. (It was around this time I discovered the Autotune fuel map feature of Tunerstudio, which made things a bit easier compared to the log, review, change, repeat method I was using previously.)

I started to pull some spark out from the base map in those areas, but then I got sidetracked a few times.

I re-scaled my fuel and spark tables to account for future boost, so this required a rework of the fueling. Top half of the fuel and spark table is obviously untuned until I have boost ready.

I then found out that a setting called "Incorporate AFR Target" would allow me to set my AFR via a separate table, and allow the VE table to actually represent the motor's real volumetric efficiency. This changes the fuel calculation completely, and I had to start my fuel tuning over again from dead rich.

I've now set up some pretty tables in excel which allow me to track my changes and give me a different visual representation of the data.

That's pretty much where I'm at now. I've only had two runs at setting up the new fuel table. To be safe I pulled a bit more spark from both the WOT high RPM area and the low kPa mid-to-high RPM area. No idea what type of fuel was used on the base tune, but I'm using Shell 91 (No Ethanol).

I've also got a bunch of other neat features figured out on the ECU. I have my SPAL fan control working, which lets me bump up the idle at the same time etc.

I have a coolant-temperature based rev limit set up to prevent revving a cold motor up too much. Nice protection if the throttle gets stuck or something along those lines. Lots of small things too like Barometric Correction.

Ran some seafoam through the motor (pulled the Wideband to avoid damage), and some water mist afterwards. Should have knocked some carbon off the internals!

Regarding spark plugs, I swapped in some Copper NGK BKR7E (4464) plugs, which are one heat range colder. I was also advised to run copper plugs as the electrode will melt/fail earlier (compared to the more expensive/longer life plugs) as a sort of failsafe if something goes wrong with the tune.

Also changed the oil with some fresh Rotella T5 15w40, and a MANN filter.

I relocated the Quadspark ignition modules away from the exhaust. They're supposed to be mounted somewhere reasonably cool, as they have their own heatsinks.

Was hoping I could build a little heat shield and get away with keeping them under the battery tray for now, but I was still getting misfiring as the area heated up (mostly while sitting still idling).

Tucked them up under the dash, can't even see them unless you stick your head underneath. Had to punch a hole in the firewall, reused an E39 gasket to make it look OEM. Bonus is the engine bay is just a little more shaved now!

Last edited by Panici; 06-13-2020, 04:51 PM.

Last edited by Panici; 06-13-2020, 04:51 PM.Leave a comment:

-

Hey Kevin,Just read your entire build thread, it's been years since I've seen it.. Glad you still have the car!! Good to see you were able to get the X3 booster to fit, I installed mine a little different and removed the "sandwitch plate" or whatever you want to call it, from the booster. It's held on with those two 13mm nuts. Cool to see it fits both ways, I didn't have to drill my firewall because I removed that plate but I did have to bend my lines pretty far inward towards the firewall, to reach the new master cylinder location.

Anyways good work man,

-Kevin

Thanks for the read-through, I know it's a little verbose in some areas.

I didn't know the sandwich plate came off, I never even thought to try! That would have been a much cleaner solution, I really didn't like having to modify the firewall.

I could also use the extra room on the front side of the master, everything is pretty tight.

If I ever have to take the booster off again the sandwich plate is going in the bin! Or maybe I'll do it just for fun when I have the motor out again. :)

Leave a comment:

-

Just read your entire build thread, it's been years since I've seen it.. Glad you still have the car!! Good to see you were able to get the X3 booster to fit, I installed mine a little different and removed the "sandwitch plate" or whatever you want to call it, from the booster. It's held on with those two 13mm nuts. Cool to see it fits both ways, I didn't have to drill my firewall because I removed that plate but I did have to bend my lines pretty far inward towards the firewall, to reach the new master cylinder location.

Anyways good work man,

-KevinLeave a comment:

-

Engine Bay Beauties, Tuning

Washed the car this morning, then went for a test & tune drive.

Have the open-loop idle sorted now, and around-town driving pretty close to my AFR targets, which are still very rich as I'm learning the ropes.

Car runs and drives great just cruising around though!

Did some more work on the mid-throttle fuel maps, but need to log more time in this area.

Also did a few WOT runs. Need to pull a bunch of fuel out, but want to sort the timing first. I moved the Vanos engagement point from 4200 to 4800 so that requires some spark changes.

Last edited by Panici; 06-09-2020, 04:29 PM.

Last edited by Panici; 06-09-2020, 04:29 PM.Leave a comment:

Leave a comment: