I couldn't do much of anything for the better part of a week, without my side spasming.

But I'm better now, and back at it.

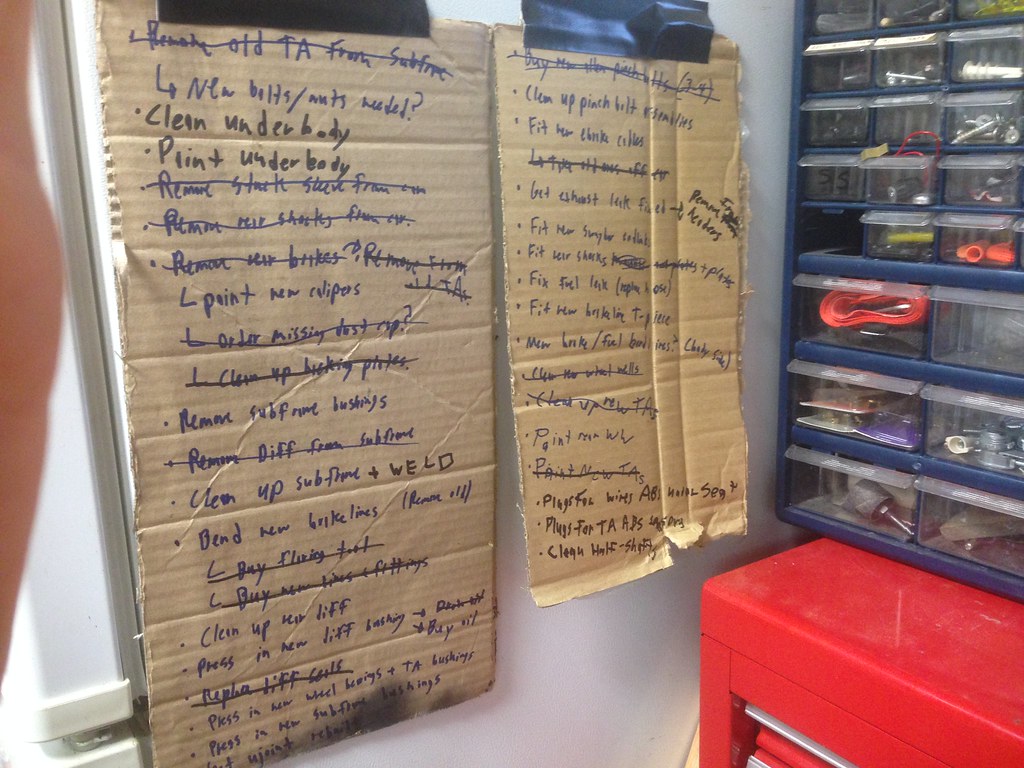

Today's progress:

- Installed new fuel filler hose.

- Old one was split around the clamp.

- Sometimes you could smell gas, and the hose leaked when the tank was full.

- Topcoated the (previously addressed) chassis spots with a high-build fleet paint

- Pressed in both new Lemfoerder subframe bushings

- Bought and then proceeded to bend an 8" C-clamp in the process.

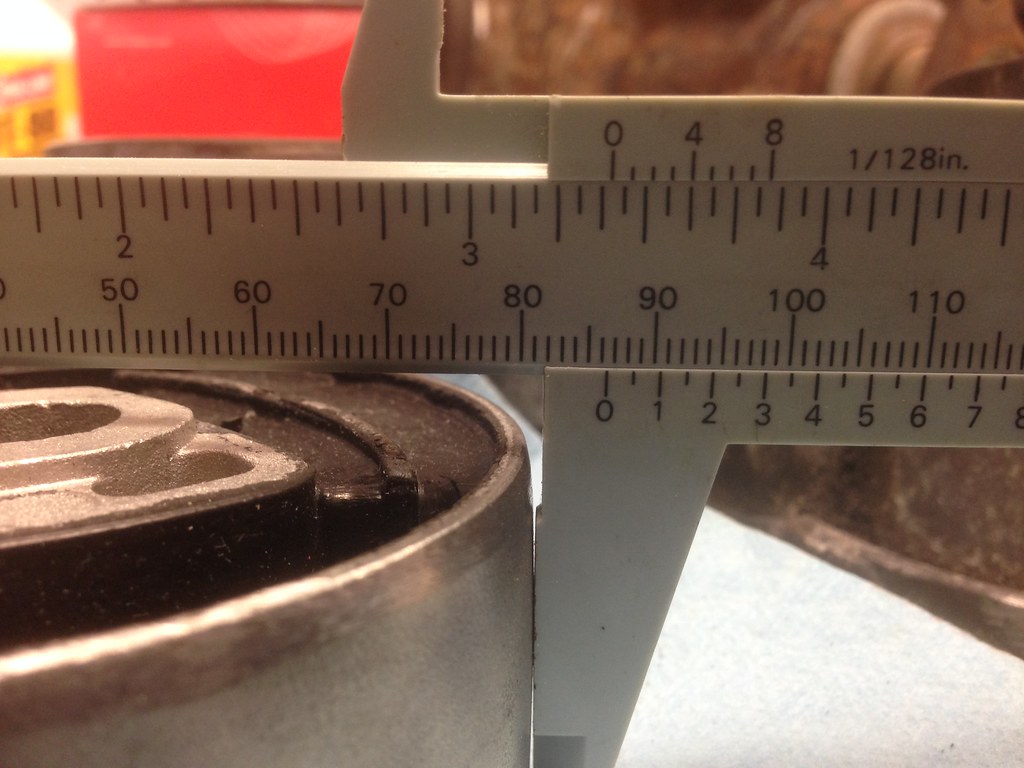

- Pressed in rear hubs into new wheel bearings

- Touched up subframe and diff POR15 in a couple spots (two coats)

- Painted the driver's side pinch bolt assembly.

Leave a comment: